Poorly maintained cooling towers could be a breeding ground for the legionella bacteria, posing a serious health hazard to those exposed to it. Glenn Dobbs discusses ways to prevent legionella growth, while achieving energy savings, through using cooling tower water filtration systems and basin agitation.

Glenn Dobbs, President of VAF Filtration Systems.

Legionella prevention has become an important topic in the cooling tower industry. Several class action lawsuits have been filed in recent years holding community officials, designers and cooling tower owners financially accountable for the publics’ safety, with the prevention of Legionella in their cooling water systems.¹ Australia has already implemented the most stringent laws in monitoring cooling tower water quality for the prevention of Legionella. This was a direct result of a Legionella outbreak at a Melbourne aquarium in 2000 that infected more than 125 people, of which more than 76% were hospitalised and four died.² Australia’s laws include cooling tower registration, Risk Management Plan reviews and audits, as well as mandatory maintenance procedures. Other countries will soon follow.

Legionella bacteria are spread exclusively by the inhalation of aerosolised water contaminated with it. Legionella symptoms are very similar to severe flu symptoms. Most people exposed are not infected, however those that are infected must be admitted to a hospital and treated for Legionella infection immediately. It could prove fatal for 10-30% of those infected, with legionella infections occurring in hospitals having higher fatality rates.¹ In many countries, Legionella infection may be misdiagnosed as pneumonia or flu, resulting in underreported occurrences, although it is known that Legionella occurs in most cooling water systems worldwide, especially in those not well maintained.

This article discusses how to prevent Legionella habitat and nutrient source buildup with proper cooling tower water filtration systems, and how this prevention will also result in significant, measurable savings in energy, maintenance, and chemical use as compared to systems without filtration.

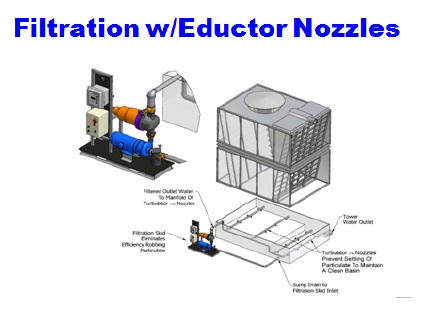

Preventing Legionella with basin agitation and water filtration

Image 1: Legionella habitat and food source

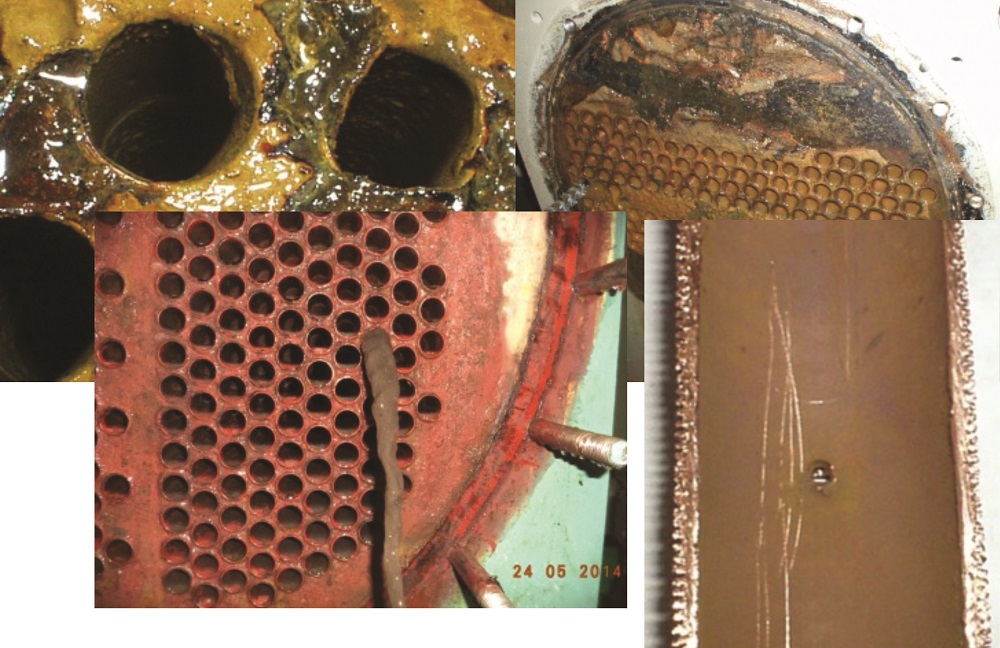

It has been shown that the habitat and nutrient source for Legionella occur in the cooling tower basin sedimentation and within the fouled surfaces of the cooling water system.3,4 (Refer to Image 1)

Corrosion inhibitors require clean surfaces to form passivation of metal. Microbiological control agents in biocides incorporating bio-dispersants are limited in penetrating sediment and surface debris. (Refer to image 2).

Image 2: Organic and microbial fouling in a

cooling tower

Legionella occur where water temperatures range from 20 degrees to 45 degrees C (68 degrees to 113 degrees F), and where nutrients are available. Ideal nutrients for Legionella consist of organics, algae, silts and iron oxide that occur in cooling towers.3,4,5

The sediment that settles in the cooling tower basin provides this nutrient source, which also harbours the bacteria from the chemicals applied to kill it. Unfiltered cooling tower water systems provide the perfect environment for Legionella to thrive, even with proper chemical treatment. Continual removal of sediment from the cooling tower basin is best achieved through basin agitation. This lifts the sediment off the bottom of the basin for removal by an appropriate automatic filtration technology. Eductor nozzles are used for this agitation, and are spaced throughout the basin floor, as shown in the following:

Filtration with Eductor Nozzles

A filtration system placed near the basin pulls water from the basin that is pumped through a filter. The filtered water is then sent back to the basin through the eductor nozzles at the proper pressure, usually 1 bar (15 psi) for agitation. Proper eductor nozzle layouts typically result in a 350-tonne tower basin volume of water being filtered about once every hour, and will typically result in 3,500-tonne and larger cooling tower basin water volumes being filtered two or more times per day. This has been found to be adequate for Legionella habitat and nutrient buildup prevention.

Filtration technologies

Automatic selfcleaning screen filtration systems can filter all types of particulate down to 10 microns

The type of filtration technology to be selected is determined by its ability to remove suspended solids that include low-density organic particles that provide the habitat and nutrient source for Legionella. An ASHRAE publication in 2000 states, “Filtration systems that remove low-density organic particles must be used since these particles provide habitat and nutrients that stimulate bacterial growth including Legionella. Centrifugal separators do not remove very small or low-density particles, and therefore are not appropriate for this purpose.”5 An appropriate filtration technology must provide a “barrier” to all particulate, including the lower density organics upon which Legionella thrive. It has been shown that centrifugal separators cannot perform this function.5,6

Appropriate filtration technologies that provide barriers to all particulate, including low-density organics, include high-efficiency sand media filters, automatic disc filters and automatic self-cleaning screen filters. Each have their own unique operating characteristics, maintenance requirements and initial costs, as described below.

[div class=”text-box text-box-left”]

In a nutshell

A cooling tower basin agitation and water filtration system:

1. Removes and prevents the buildup of the habitat and nutrient source for Legionella and allows the chemical treatment to penetrate these areas to kill Legionella.

2. Reduces fouling of the heat transfer surfaces, which enhances scale and corrosion inhibitor treatment, and is known to likely reduce energy consumption more than 10% when compared to systems without filtration.

3. Reduces chemical costs of water treatment by 14%.

4. Reduces maintenance labour costs required to clean the cooling tower, basin and chiller by 80%.

5. Does not increase water consumption of system, since the backwash usage simply extends cycles of concentration.10

[end-div]

High-efficiency sand media systems are stated to have the advantage of removing particulate down to 0.5 to 1 micron in size. These systems are known to have significantly higher water usage for the automatic backwashing of the media. A 225 m3/hr (1,000 gpm) high-efficiency media system typically uses more than 4,500 litres (1,200 gallons) for each cleaning cycle. The filtration process is taken off line for backwashing of the media. The backwash water waste is sent to the drain, along with the chemical treatment in it. Also, the media in these systems require periodic replacement and must be purchased from the media system manufacturer to meet performance expectations. The cost of a high-efficiency media system is two to three times higher than an equivalent automatic disc or automatic screen filter system with the same flow rate.

Automatic disc and screen filtration systems can remove all particulate down to 10 microns. So the additional particulate a media filter can remove is from one to 10 microns in size, which consists of about three per cent of the total volume. This has been shown by obtaining particle size distribution by volume of several cooling water systems and measuring the total volume between one micron and 10 micron particle sizes. The result is, high-efficiency media will remove about three per cent additional particulate by volume for two to three times the capital cost of disc or screen filtration.

Automatic disc filtration systems have the same particle removal capacity of screen filtration systems. Disc filters require backwashing in the same way as described herein for media filtration, but at much higher pressures and, therefore, have a relatively high energy and water waste requirement for backwash. Disc filtration systems cost about the same as automatic screen filtration systems, but have higher maintenance costs and become more expensive as the required filtering flow rate increases.

Proper eductor nozzle layouts typically result in a 350-tonne tower basin volume of water being filtered about once every hour

Automatic self-cleaning screen filtration systems can filter all types of particulate down to 10 microns. They require a smaller footprint and the flush waste is the least. A 225 m³/hr (1,000 gpm) system will require about 55 litres (15 gallons) of water for each screen cleaning cycle. The filtration process is uninterrupted while cleaning the screen. There are fewer parts and, therefore, less maintenance is required than with disc filters.

A large entertainment complex in Australia tried several filtration technologies before ending up with automatic screen filtration systems. The maintenance engineers determined that automatic screen filtration resulted in improving cooling tower cleanliness, heat transfer efficiencies and chemical treatment effectiveness, as well as reducing backflush water loss and maintenance costs associated with the other filtration technologies.6

Energy savings

Cooling tower water filtration maintains efficient cooling tower performance and keeps chiller tubes clean to maintain high heat transfer efficiencies. In the cooling tower, the following fouling that occurs without filtration reduces cooling efficiencies:

• Fouled water distribution nozzles prevent the even flow of water to be cooled over the fill pack.

• Fouled fill pack causes water channelling, which prevents even water flow and reduces surface water exposure for cooling.

• Water channelling allows dissolved hardness salts and suspended solids to build up in the dry areas of the fill. This compounds the problem of fouling, deposition, nutrient and restricting air flow.

• Fouled drift eliminators restricts air flow, which further reduces the cooling capability of the cooling tower.

Images 3 and 4: Fouled cooling tower fill

Scale, solids and bio-fouling restrict air and water passages reducing cooling performance.

A cooling tower’s cooling efficiency is known by measuring its approach temperature (difference of the cooled water exiting the tower and ambient wet bulb temperatures). Most cooling tower manufacturers have a design approach temperature that ranges from three degrees C to 4.5 degrees C (5.4 degrees to eight degrees F). In Asia, it has been found that a new cooling tower after six months of operation will have an approach temperature of seven to eight degrees C (12.6 degrees to 14.4 degrees F), resulting in about 14% energy loss.

Image 5: Fouled heat exchangers

In the heat exchanger/chiller, the heat transfer surfaces are fouled without the use of filtration. It is known that only 0.25 mm of surface fouling on heat transfer surfaces reduces heat transfer efficiency by as much as 10%.7 A chiller’s heat transfer efficiency is known by measuring its approach temperature (difference between the chiller’s exiting water and its saturated refrigerant temperatures). A clean efficient chiller will typically have an approach temperature ranging from two to four degrees C (3.6 degrees to 7.2 degrees F).

It has been shown that chiller energy increases 3.6% for every one degree C (1.8 degrees F) increase in condenser approach temperature.7 This increase in condenser approach temperature may be caused by both an increase in cooling tower exit water temperature and the fouling of the heat transfer surfaces in the chiller.

It is easy to show how a filtration system can improve energy efficiencies by 10% or more, by keeping both the cooling tower and the heat exchanger/chiller clean.8

Other savings attained with cooling tower water filtration

Legionella habitat and nutrient buildup prevention with filtration as described herein results in other benefits. The US Department of Energy conducted a test comparing the performances of two cooling towers sitting side-by-side, one with filtration and the other without filtration.9 They demonstrated that the cooling tower with water filtration:

• Reduced chemical costs by 14%

• Reduced labour to clean the cooling towers and chillers by 80%

Summary

It is evident that cooling tower water filtration systems with basin agitation, help in the prevention of Legionella bacteria habitat and nutrient buildup in the cooling water system. Eliminating the food source and habitat where Legionella hide and thrive will allow the water treatment programme to kill the bacteria. All cooling tower systems differ, and are exposed to different environments. Maintenance programmes and system ages vary. The numbers given herein estimating savings are provided to give a sense of the magnitude of what is possible.

References

1. A Legal Perspective on Legionella, by Andy Jones, ESQ., Spring 2015, American Association for Justice

2. An Outbreak of Legionnaires’ Disease at the Melbourne Aquarium April 2000: investigation and case–control studies, by Jane E Greig, John A Carnie, Graham F Tallis, Bernard Zwolak, William G Hart, Charles S Guest, Norbert J Ryan, Jennie A Leydon, Agnes G Tan and Ian R Gordon, The Medical Journal of Australia, Volume 180, 7 June 2004

3. Legionella: Human Health Criteria Document, EPA- 822-R-99-01 November 1999, Office of Science and Technology Office of Water, Washington DC

4. OSHA Technical Manual, Section III: Chapter 7

5. “Filtration systems that remove low-density organic particles must be used since these particles provide habitat and nutrients that stimulate bacterial growth including Legionella. Centrifugal separators do not remove very small or low-density particles, and therefore are not appropriate for this purpose.” Controlling Legionella in Cooling Towers, ASHRAE IAQ Applications Technical Feature Spring 2000 by Craig Meyer.

6. Largest Entertainment Complex in the Southern Hemisphere Improves Cooling Tower Filtration – Reduces Maintenance and Treatment Costs, by Glenn Dobbs, VAF Filtration Systems, USA, and Roy McDougall, Hydrochem Water Treatment Systems, Australia 2014

7. Cooling Tower Operation and Maintenance for Improved Energy Efficiency. Presented at the AHR show by Kavita Anuje, Trevor Hegg and Paul Lindahl, January 2004.

8. Side Stream Filtration for Cooling Towers, U.S. Department of Energy Federal Energy Management Program, October 2012.

9. Evaluation of Side Stream Filtration Technology at Oak Ridge National Laboratory, U.S. Department of Energy, September 2014 10. The ROR of Cooling Tower Water Filtration, by Glenn Dobbs, VAF Filtration Systems, USA, and Roy McDougall, Hydrochem Water Treatment Systems, Australia 2015

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Glenn Dobbs is President, VAF Filtration Systems. He can be contacted at gdobbs@vafusa.com.

Copyright © 2006-2025 - CPI Industry. All rights reserved.