Company says it is the first time ever that a VRF manufacturer has received the global honour

QINGDAO, China, 4 December 2024: Hisense said the World Economic Forum (WEF) on October 8 officially announced that the Hisense Qingdao Factory has been selected for the global ‘Lighthouse Factory’ list. Making the announcement through a December 4 Press Release, Hisense said it is the first time ever that a VRF industry representative has received the global honour pertaining to the manufacturing sector.

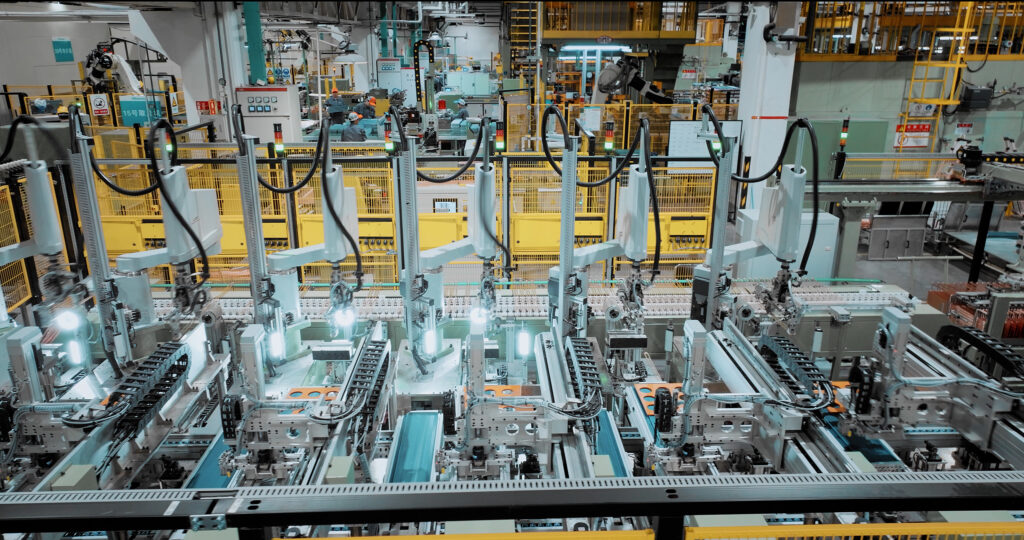

According to Hisense, by introducing advanced 4IR (the 4th Industrial Revolution) technologies and concepts, the Hisense Qingdao Factory has realised the leap upgrade on agile R&D, flexible production and agile delivery. Over 40 advanced manufacturing scenarios have been created here, with more than 20 technologies being industry firsts, increasing product development speed by 37%, improved labour productivity by 49%, and reduced production costs by 35%, Hisense said.

Based on machine vision guidance, AI algorithms and equipment interconnection, Hisense said, it has overcome 20+ automation challenges in the industry, establishing the industry’s first dark production workshop for heat exchangers, introduced adaptive welding automation and multi-stage integrated automation, and implemented unmanned packaging. In the automated welding process, Hisense said, it has pioneered multi-spot welding, non-uniform heating, high-precision visual guidance and parameter compensation solutions, achieving a 63% increase in labour efficiency and a 57% reduction in welding defects. And in the logistics segment, Hisense said, it has creatively introduced the overhead crane into the VRF industry to enhance logistics quality and efficiency.

The advancement of Hisense factory lies not only in manufacturing, the company said. With the goal of intelligence and efficiency, its supply chain built an AI-driven end-to-end intelligent decision-making and agile delivery operation system, it said. Using AR and VR technology, Hisense has made employees’ learning more intuitive, greatly improved the training efficiency and enhanced employee skill levels, the company

claimed. In order to enhance the operational efficiency, Hisense said, it has established a KPI-driven digital twin operation platform, achieving real-time transparent management of KPIs, developing comprehensive alert perception and automated tracking capabilities. And through IoT technology, Hisense said, it has successfully achieved digital energy management and accurate control of energy consumption. Moreover, by implementing energy-saving technology for high energy consumption equipment, the factory achieved AI intelligent control for production and testing equipment, reduced the unit energy consumption by 38%, Hisense said.

Kiva Allgood, the head of the WEF Centre for Advanced Manufacturing and Supply Chains, said, “The lighthouse factories are improving the standards of the digital transformation. These advanced technologies are not only to improve the production efficiency of the company but also to create an inclusive and sustainable future for employees and society.”

Hisense said winning the honour of the world’s first VRF lighthouse factory is not only an indication of the successful practice of Hisense’s digital transformation strategy, but is also a reflection of the firm commitment to technology and quality. In the future, Hisense said, it will continuously improve its manufacturing level, establishing a digital model for the development of the HVAC industry, and contributing Hisense’s strength to promote the prosperity of the global manufacturing industry.

Dharmesh Sawant, GM of Hisense HVAC, UAE Branch, said: “At Hisense HVAC, our team always strives to add value in the design of HVAC system of our customers’ homes with not only product innovations but also with design and aftersales process innovation. With this, we are aligned to make Hisense HVAC as the most reliable brand, globally. In design, we always find ways to add redundancy factor, reduce the operating power consumption and lower life cycle cost. Through product innovations, we address some challenges of customers with features like humidity control/setting, demand control, self-cleaning function, high EER and IOT-based controllers. With aftersales process, we are always carefully monitoring the installation process, commissioning and start up with the help of our distributors, authorised service providers and authorised installers.”

Copyright © 2006-2024 - CPI Industry. All rights reserved.