Johnson Controls

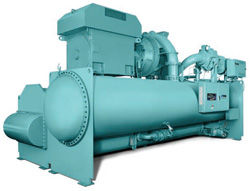

Saying that it is an ideal choice for large chilled water plants, Johnson Controls (JCI) has introduced the YORK model YK-EP Energy Plus chiller. With a capacity range of 2,500 to 3,200 TR (8,800 to 11,200 kW), the YK-EP chiller is an ideal choice for large chilled water plants, the manufacturer claims.

According to Johnson Controls, the product features a patent-pending, mechanical-compression economiser cycle, which provides increased capacity and improved efficiency. As a result, claims Johnson Controls, the unit delivers the industry’s highest design efficiency of any large-capacity centrifugal chiller. This translates into significant energy savings at off-design conditions, where 99% of chiller operating hours are spent, it adds. This, says Johnson Controls, is due to the chiller’s ability to utilise entering condenser water temperatures (ECWT) as low as 13oC.

According to Johnson Controls, the product features a patent-pending, mechanical-compression economiser cycle, which provides increased capacity and improved efficiency. As a result, claims Johnson Controls, the unit delivers the industry’s highest design efficiency of any large-capacity centrifugal chiller. This translates into significant energy savings at off-design conditions, where 99% of chiller operating hours are spent, it adds. This, says Johnson Controls, is due to the chiller’s ability to utilise entering condenser water temperatures (ECWT) as low as 13oC.

The manufacturer lists the following product features and advantages:

Lower ECWT reduces instantaneous energy consumption by as much as 50% compared to chillers limited to a minimum ECWT of 24oC.

Off-design performance can be further improved by adding a YORK OptiSpeed variable-speed drive, which can trim average annual energy consumption by 30% or more.

In central utility plants and district cooling facilities that use multiple chillers, additional energy savings can be achieved by piping the chillers in a series-counterflow arrangement. This reduces the compressor work on each chiller and cuts system energy use by as much as eight per cent at design conditions.

The chiller’s high-efficiency performance helps buildings qualify for LEED points in the Energy and Atmosphere Credit 1 (EAc1): Optimise Energy Performance category.

It reduces additional ownership costs: when equipped with an OptiSpeed drive, the unit reduces installed cost with its ability to accept medium or high-voltage power. Higher voltage power reduces distribution losses, voltage-transformer requirements, and power cable size, improving system efficiency and cutting installation costs.

Installation costs can also be reduced by the chiller’s shipping configuration: It ships in a disassembled arrangement, consisting of three pieces that are less expensive to ship, easy to move into place, and easily reassembled.

Maintenance costs are lower because the YK-EP chiller’s compressor drivelines utilise open motors. If a motor failure occurs, the chiller can be brought back online quickly and cost-effectively, reducing downtime.

It improves plant sustainability by using refrigerant HFC-134a, which has zero ozone-depletion potential, low global-warming potential, and no phase-out date.

Because of reduction in refrigerant charge, buildings using the YK-EP chiller can qualify for the maximum LEED points in the Energy and Atmosphere Credit 4 (EAc4): Enhanced Refrigerant Management category.

Copyright © 2006-2025 - CPI Industry. All rights reserved.