Independent, industry factory-trained and certified chiller service specialist organisations offer superior services and solutions.

A few months ago, a local energy services company (ESCO) in the UAE approached my team and I with the stated objective of wanting to save energy at a site featuring a few air-cooled screw chillers, a mix of two OEMs.

Dan Mizeko

It didn’t really matter to my team and I which OEMs the ESCO was talking about, as the story is all too often the same. Anyway, the ESCO informed us it wanted to install VFDs on the screw chillers. We responded by saying we could help, as we have an engineered package under which we would install the VFDs, a new chiller microprocessor-based control system and other accessories required to successfully perform the energy retrofit.

The ESCO immediately approved the project, and the subsequent result was a success story with over 30% savings to the customer when compared to the chillers’ previous energy consumption. During our discussions with the ESCO, we learnt that the company had approached the two OEMs and requested their assistance; and what followed is always the same story. The OEMs said they did not have a factory upgrade package for the chillers and suggested that the ESCO purchase new chillers with VFDs already installed.

This did not make sense, as the chillers were not even five years old, and installing new chillers would have been cost-prohibitive, to say the least. Not to mention that this would have defeated the purpose of the sustainable approach to retrofit the chillers, as opposed to replacing them. A retrofit results in reducing waste and allows for continued use of resources already in service, which would not have been possible by resorting to the easy but unsustainable decision of disposing of the chillers.

Professional independent chiller service specialist companies offer aftersales services second to none. Independent chiller service organisations have dominated the chiller after-sales market in the United States since the 1980s but were yet to appear anywhere in the Gulf until recently. Properly structured independent service organisations are vastly more well-rounded, with their chiller engineers working on all OEM chillers and are factory- and industry-trained and certified on the equipment they service.

Independent chiller service organisations protect the customers. To be frank, we have found many potential customers informing us they would like to utilise our services but due to a chiller “being under warranty” not being able to use us. First of all, utilising the services of an outside third-party specialist chiller organisation does not void any warranties. It’s truly disturbing that this myth is being perpetuated. Second and most important is that during this most critical point in time – I am referring to the warranty period – it is vital a third-party independent specialist chiller organisation be engaged to protect the chiller owner’s best interests.

In the case of my team and I, since we aren’t tied to any of the chiller manufacturers, we serve the customer, not them – the factory. We are able to provide recommendations that benefit the customers not the chiller manufacturer. During the warranty period, we come in and verify that the chiller commissioning has been performed correctly, including its efficiency per Kw/ton and its capacity and tonnage production.

A few months ago, I wrote that chiller commissioning is the most critical part of the chiller being put into beneficial service. I think it important that I revisited this topic, so that its significance is not overlooked.

FACTORY WITNESS PERFORMANCE TEST

Most companies who purchase centrifugal chillers for their facilities, demand a Factory Witness Test of the chillers they are buying before accepting delivery and payment. The OEM Sales Engineer would select the chiller with a software selection program to predict the chiller’s performance. The buyer agrees to purchase the chiller based on the program’s predictions of the chiller performance, including capacity part load and full load and also kW/ton, to name just a few of the parameter performance predictions. The Factory Witness Test confirms that the chiller performance matches the predicted performance and the results serve as a benchmark.

AHRI STANDARD 550/590

The witness testing standard requires specific types of instrumentation and specifies chiller testing procedures and tolerances. It also requires that accurate measurement is an integral part of Witness Performance Testing. All of the following instrumentation must be calibrated and traceable to the National Institute of Standards and Technology (NIST): Power meters, temperature sensors, flow meters and pressure transmitters.

This ensures the instrumentation meets the accuracy requirements of AHRI Standard 550/590. A copy of the latest calibration report is made available to the attendees of the Witness Test. As per industry standards, the factory test loop must have redundant measurement devices designed into test loops to verify test data. Redundant sensors are used to measure evaporator water flow, evaporator water temperatures, condenser water flow, condenser water temperatures and chiller power consumption. Agreement between the calibrated sensors confirms that the data taken is accurate.

Some companies even require a zero-tolerance witness test to be performed. In other words, the chiller must perform at its predicted design performance; if not, the buyer is at liberty to cancel the sale.

I have been involved in many Factory Witness Tests over the years, and I can tell you it takes the factory days to prepare the chiller for the test, getting everything right so that the chiller performs as designed. Even with the days of preparation, the chiller will often not perform to design kW/ton. More days of adjustments must be done to finally achieve design performance, sometimes including changes to the chiller’s design. When the chiller is certified and meets design conditions, a printout is given to the buyer to benchmark that the chiller performs as predicted.

CHILLER START-UP AND COMMISSIONING IN THE FIELD

Does anyone reading this think that when a chiller is started and commissioned in the field, it receives the same amount of attention, care and diligence as a Factory Witness Test? Are the proper and precise tools and equipment utilised in the field as during the factory Witness Test? Is the same data looked at during the field startup as during the Factory Witness Test? Is the chiller kW/ton even checked during a field startup as it is during a Factory Witness Test? Finally, is the Field Startup Technician as trained and aware of how the chiller should perform as the Factory Witness Test personnel? Of course, the answer to all the above questions is a big ’no’.

After answering all the above questions as ‘no’, how could chillers ever operate as efficiently as designed? As the data shows, chillers do not operate as efficiently as designed. The first reason is ineffective startup and commissioning from Day One of beneficial usage.

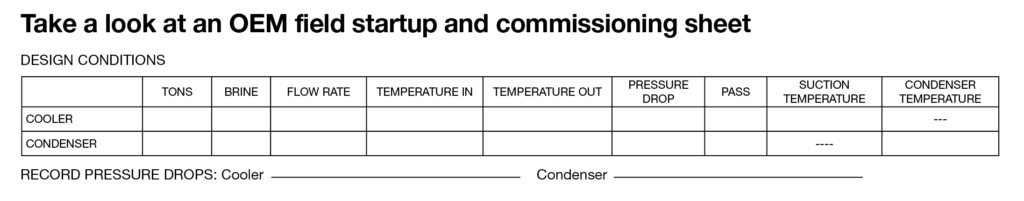

The above is a small section taken from an OEM commissioning manual. I want the reader to understand the design condition that the startup technician is to record. Does it mention kW/ton? No. Also, what’s interesting is that the flows are to be determined by pressure drop readings. The Factory Witness Test is performed with a calibrated flow meter; however, the startup technician sets design flow with an instrument that is not nearly as accurate as a flow meter. My point is that energy efficiency is not a priority or even checked during the initial startup and commissioning of the chillers.

It is in every owner’s interest that an independent third-party chiller specialist organisation be engaged to determine that the start-up and commissioning have been performed to above the “industry standards”. In addition, during the warranty period, the third-party organisation can make you aware of a warranty issue that a factory chiller service company may have overlooked and not spotted.

Here’s another case-in point: Over a year ago, we were called in by a client to determine the root cause of many compressor failures at a site with well over 20 air-cooled chillers. After analysis, we determined that the compressor cooling lines, owing to a design shortfall, were to have been factory-retrofitted to improve the cooling. We informed the customer of this and, subsequently, the customer approached the OEM factory to perform the factory retrofit. The fact is that if we, an independent, unbiased third party, had not been engaged, it never would have come to light that the factory had not performed the retrofit, and it never would have been performed.

I will not speculate why the factory warranty retrofit was overlooked; however, I can say that had it not been for us identifying the issue, the retrofit would not have been performed – and free of cost at that.

Independent third-party chiller specialist organisations in the United States are often members of large independent service organisations, such as the Independent Contractors Exchange Group (ICE), which is a group of contractors specialising in installation, operation, repair and maintenance of large commercial and industrial cooling systems and building and process control systems.

The ICE group’s mission is to improve the people, the companies and the industry through technical support and training, sharing of best practices and through maintaining positive relationships with strategic partners in the industry.

The ICE group’s objectives are:

Through the group, independent, third-party specialists in the United States receive the very same training as the factory technicians. What’s also powerful is that the training is on all OEM chillers, whereas the factory technicians do not get cross-trained on other OEM chillers.

The power of the group is unprecedented. The group consists of members from the 50 most proficient independent chiller services companies in the United States, who work together to share technical and business best practices so that the group members’ customers receive the finest solutions and services available in the industry.

What is also very interesting in this is that all major OEMs of chillers participate in the ICE group and introduce their latest technologies and training to the group. In fact, the group receives preferential training from all the major OEMs that no other service organisations have access to.

The group also supports each member with sharing of human resources, parts, service bulletins, manuals and technical solutions that no single organisation could amass on each and every major chiller manufacturer’s equipment. The group also has a “Technical Questions” service, whereby any situation regarding chiller service, repair or troubleshooting can be sent via email, and someone who specialises in the subject within the group’s over 1,200 individual members would respond with the answer to support the other group members.

There is a power of having the ability to reach out to over 1,200 of the most highly skilled and trained engineers and technicians worldwide, and only an independent contractor has access to this group.

Obviously, I recognise the fact that there are good factory service offices out there and bad independents. But by and large, the notion that the “OEM knows best” is simply not true. If you’re looking for more solutions from a capable organisation, you will win nearly every time by choosing an independent specialist chiller organisation in your city.

Dan Mizesko is Managing Partner/President, U.S. Chiller Services International. He may be contacted at dmizesko@uscsny.com

Copyright © 2006-2025 - CPI Industry. All rights reserved.