We analyse cooling optimisation through combined VSP and PICV installations

Climate Control Middle East analyses cooling optimisation through combined VSP and PICV installations

As topics go in a region that captures just one percent of the world’s available fresh water, yet hosts 5% of the world’s population, the issue of energy consumption doesn’t get much hotter.

Add international climatic pressure, existing and incoming regional strategic targets and a shiny new end-user driven business model to the mix, and in-depth evaluation of energy efficiencies becomes compelling.

The design, construction, operation and maintenance of cities and communities has a huge impact on natural resources and the environment. The challenge is to build smart throughout the supply chain.

With this in mind, Climate Control Middle East paid a visit to Technoflow at its testing and development laboratory, headquartered in Dubai. Below we bring you straight forward information on how HVAC energy savings can be achieved through a combination of variable speed pumps, PICVs, pressure sensors and control valves.

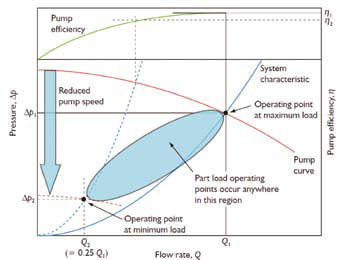

Fig 1. Varying conditions in a system with pump pressure controlled to maintain constant pressure at system extremities (Source: CIBSE KS 7)

Until recently the majority of large chilled or heated water based air conditioning systems were designed for constant flow and utilised three or four port temperature valves to divert the required amount of water flow through in room heat exchangers, such as fan coils. The local heating or cooling load is influenced by a number of factors including the outside air temperature which will vary over the year and therefore, cooling or heating degree days vary over the year as outside air temperature changes.

Cooling or heating water, whilst providing an effective method of indoor climate control by pumping it around a building, if the heat exchanger is bypassed at the last moment without extracting the absorbed heat, this is extremely wasteful in energy. As the full heating or cooling load on a building occurs for 5% or less of the year, it is extremely important to match the power absorbed into a heating or cooling system to the actual load placed upon it.

Manufacturers of pumps, fans and other equipment have successfully utilised variable speed drives that can slow motors to reduce power consumption at periods of low demand.

By combining variable speed pumps and two port temperature control valves (that throttle closed rather than divert through a bypass port) together with pressure sensors and pump controllers, a water based air conditioning system can operate under variable flow conditions in response to the varying heating and cooling loads on the building.

Due to the pump affinity laws, if pump speed is reduced to 25% of its maximum then the flow is also reduced to 25%, the pump head is reduced to 6.25% and the pump power output is reduced to only 1.6% (i.e. 0.25% of 6.25%) of its maximum. Actual pump power consumption (electrical energy) is likely to be a little higher than 1.6% due to a reduction in pump efficiency, as shown in Fig 1., but this will be marginal.

Unfortunately there are unwanted pressure fluctuations in the pipework as pumps change speed and two port valves open and close in a variable flow system. These result in underflows and overflows and corresponding undercooling and heating or overcooling and heating at the part load condition. However, this unwanted side effect can be managed by careful use of differential pressure control valves or the installation of pressure independent balancing & control valves at each of the in room heat exchangers.

A recent study conducted by Frese and Grundfos in Denmark demonstrated that when a variable speed pump, end point pump sensor and pressure independent balancing & control valves (see Fig. 4) were installed on a typical variable flow system then 76% of electrical pump energy consumption could be saved relative to the same system fitted with a constant speed pump and manual balancing valves.

Furthermore overflows and underflows were eradicated and supply and return water temperatures were guaranteed as the system remained dynamically balanced at all load conditions.

Despite the dramatic savings in pump electrical energy consumption, this is only half of the story, due to beneficial effect of maximising ΔT (the difference between system supply and return temperature). The energy consumption of a chilled water cooling system is comprised of three main parts, i) the energy cost to chill the water, ii) the energy cost to pump the water around the system and iii) the energy loss from the return pipework.

It is also very important to maintain a high ΔT in efficient heating systems in order for condensing boilers to work in condensing mode at all load conditions.

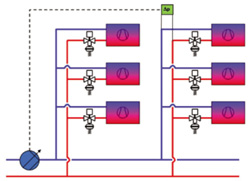

Fig 4. Variable speed pump with end point control and pressure independent balancing & control valves

The cost to operate the chiller can typically account for as much 40% of the energy use in cooling systems but their efficient operation is often impaired due to elevated return temperatures caused by overflows in variable systems or blending of supply and return water in primary headers or through chillers that have been staged off.

Furthermore, on large distribution systems, the heat losses from lengthy return pipework can be minimised if the return temperature is maintained as close to atmospheric temperature as possible.

Pressure independent balancing & control valves maintain system design ΔT at all load conditions and eradicate losses through inefficient chillers working when they are not required and by minimising the temperature gradient to atmosphere in the return pipework to the plantroom.

Copyright © 2006-2025 - CPI Industry. All rights reserved.