Arguing that unclogging of filters plays a critical role in ensuring better Indoor Air Quality, Dr Iyad Al-Attar demonstrates why it is important to determine when and how clogging occurs.

In hot climates, such as the GCC region, possibly the second thing we do after switching on our car engines is to turn on the air conditioning. And we get frustrated when it doesn’t start blowing sufficient amount of cold air immediately and begin to wonder what we could do to remedy the situation. The signs of discomfort start with reduced air flow, increased indoor temperature, concentration of pollutants and, finally, it could be due to the vehicle compressor attempting to protect itself by using an automatic safety shutoff feature after detecting abnormal pressure change.

When this happens, we rush to the nearest mechanic’s garage to locate the problem and get a satisfactory solution. Chances are that he will pull a clogged cabin air filter. Our immediate reaction to this would be, “No problem; we can just replace the filter and we are back on track.” This is because we believe that a clogged filter affects only the air conditioning system. But, in fact, filter clogging makes the vehicle’s engine spin faster to provide the required power for the air conditioning system to operate. This, consequently, reduces the power reaching other components in the car, such as the alternator. Ultimately, since more power is diverted to meet the needs of the air conditioner, the overall engine horsepower and performance could suffer [1].

By the same token, allowing the air filter in an air handling unit to clog could risk filter structure failure, such as disintegration or media rupture. When this happens, the dust filter becomes the source of contamination and the air handing unit becomes the driving force behind the distribution of dust collected over a span of its lifetime. The contamination the occupants in the indoor space are exposed to, apart from the damage to the HVAC equipment, is simply incomprehensible.

WHY IT’S IMPORTANT TO DETERMINE FILTER CLOGGING

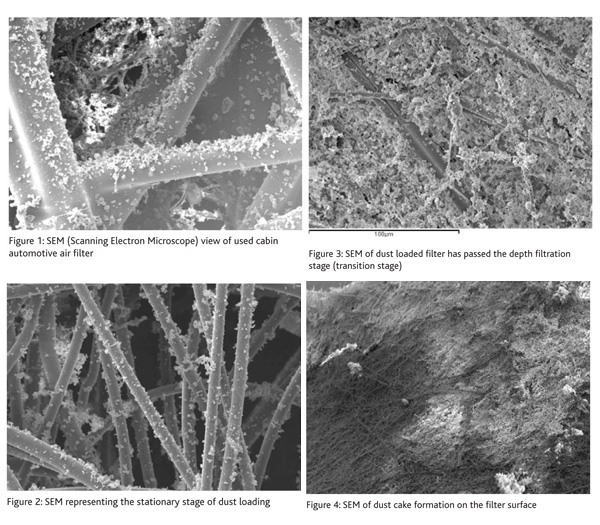

It is evident that instead of finding quick-fix solutions, we need to go to the root cause of clogging. Understanding filter clogging enables gas turbine and HVAC designers, engineers and managers to determine the lifetime and pressure drop where filter replacement need to take place. When dust loading occurs, filter structure changes internally, whether particles deposit within the media, or externally, if deposited on its surface to form a new layer of dust. Such change in structure affects the pressure drop response of the filter, which also depends on air velocity. As far as particle size is concerned, finer particles cause higher pressure drop, and are considered to cause more clogging than larger particles [2].

In examining the lifetime of a filter which may end when a recommended final drop is set to replace it, a typical pressure drop curve undergoes three phases of interest:

While filter clogging may be inevitable in certain cases, delaying the dust cake formation by extending the depth filtration phase extends the life time of the filter and causes lower rise in pressure drop. One could easily say that efficiency enhancement of an air filter can be achieved by increasing its depth using successive layers. This may be possible. However, the rise of pressure drop versus the gain in efficiency may not be justifiable. Further, there are other parameters that need to be considered, such as particle concentration, size and the depth deposition occurrence relative to the filter medium pore size. Therefore, the role of these parameters has to be considered in order to examine the possible enhancement of both filter lifetime and efficiency. Protecting the filter by introducing pre-filters or reinforcing the existing ones can be a great help in decreasing the dust concentration of the particles arriving at the final filter. In other words, pre-filters help the final filter deal not only with smaller particle size range but also with lower concentration.

FILTER LIFETIME

Filter lifetime is an important aspect of the filtration process, since it has economic implications. Manufacturers, engineers and end-users are interested in extending the lifetime of the filter, especially fine and absolute filters. The fact remains that there are a couple of important consideration that need to be kept in mind at this stage of the discussion:

When dust particles get deposited within the depth of the filter, the filter’s characteristics undergo important changes and the filtration performance gets more complex to describe. Filtration statics describe the filtration parameter of an initial or clean filter performance during dust-loading. The filtration dynamics become, indeed, very challenging, since it is a time-dependent filter characteristic that is used in describing the filter clogging process.

HOW DUST CAKE GETS FORMED

It is very common to see maintenance crew relying on a single filtration stage, such as a fine filter, to counter the atmospheric air with its entire particle size distribution. This simply means speeding up dust cake formation on the surface of the filter to an extent that the particle depth deposition is minimised. In fact, what actually happens at this juncture is that the fine filter deals with greater dust concentration and larger particle sizes than it should. In other words, greater dust concentration promotes dust cake formation, which can be formed by a combination of two primary mechanisms – bridging and complete blocking.

WHAT’S THE WAY OUT?

Certainly, there appears to be no way out! But one significant way to surmount the problem of dust cake formation is to bring it under the analytical knife. This will facilitate a better understanding of the problem of filter clogging. It is no surprise that several parameters influence dust cake formation and filter clogging. These can be categorised under the following heads. They could give a cursory view of the area of research that warrants in-depth understanding and analysis.

Researchers in the past have relentlessly studied the phenomenon of dust cake formation and filter clogging. CN Davis in his famous book, Air Filtration theoretically defined the increase of filter resistance and collection efficiency as a result of clogging in 1970 [4,5]. Several other researchers have attempted to describe the pressure drop of dust loaded filters. However, their approaches required knowing the dust packing density, which is hard to obtain even experimentally.

BORN TO GATHER DUST

We all believe that air filters are born to capture dust and other contaminants. However, the idea is not only to eliminate dust cake formation, but also to ensure that the filter media depth has been utilised prior to dust cake formation or filter clogging. Dust-loaded and clogged filters need to be dealt with in a professional manner and methodically, especially during replacement and transportation, in order to ensure no further damage is done to the indoor environment and its human occupants.

Dr Iyad Al-Attar is an Air Filtration Consultant. He can be contacted at: iyad@iyadalattar.com

References:

[1] www.ehow.com

[2] Japuntich D.A., Stenhouse J.I.T., and Liu B.Y.H., 1994, “Experimental Results of Solid Monodisperse Particle Clogging of Fibrous Filters”, J. Aerosol Sci, 25(2), 385-393.

[3] Neiva A.C.B. and Goldstein L. Jr., 2003. “A procedure for Calculating Pressure Drop During the Build-up of Dust Filter Cakes”, Chemical Engineering and Processing, 42(6), 495-501.

[4] Davies C.N. 1970. “The Clogging of Fibrous Aerosol Filters”, J. Aerosol Sci., 1(1), 35-39.

[5] Davies C.N., 1973. Air Filtration, Academic Press, New York.

NOTE: Unless otherwise mentioned, all graphs and data are copyright of the author.

Copyright © 2006-2025 - CPI Industry. All rights reserved.