The performance of centrifugal chillers could be optimised by combining the new technologies of magnetic bearings and variable speed drives, along with HFC refrigerants.

The performance of centrifugal chillers could be optimised by combining the new technologies of magnetic bearings and variable speed drives, along with HFC refrigerants.

Till quite recently, centrifugal chillers were not taken into account as a major factor for sustainable efficiency improvements while considering a building’s energy consumption. The high operational efficiency at full load was a major consideration while buying centrifugal chillers. However, now, the other side of the coin has revealed the main limitations regarding part-load performance, maximum condensing temperatures above 40°C and the inability to operate at low cooling loads.

Presently, the changed attitude is that overall economics on lifecycle basis demands much more than peak loading. This is because it has been proved that a typical chiller operates less than one per cent per year on peak load. However, the solution is at hand now: A groundbreaking trend in centrifugal chiller applications has been launched with advancements in the field of variable speed drives with HFC refrigerants that drives the chiller oil-free with magnetic bearings, making them highly efficient and superior in terms of energy consumption and lifecycle costs. The new centrifugal technology is available in typical screw chiller sizes (from 60TR), and because of the high condensing temperatures, also in an air-cooled and evaporative versions.

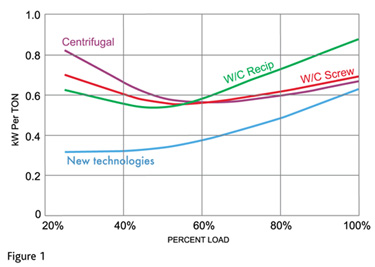

Conventional systems show that if building load decreases, the chiller responds by partially closing its inlet vanes to restrict refrigerant flow. While this control method is effective down to about 20% of a chiller’s rated output, it results in decreased operating efficiency. This implies that a conventional centrifugal chiller, rated at 0.6 kw/per tonne at full load, might require as much as 0.8 kW per tonne when very lightly part-loaded (Figure 1).

Magnetic bearing technology

Magnetic bearing technology

Since chillers typically operate at or near full load less than 10% of the time, part-load operating characteristics significantly impact annual energy requirements. The answer to improving a centrifugal chiller’s efficiency, therefore, is to drive it with variable speed drives with HFC refrigerants and oil-free with magnetic bearing technology.

The totally oil-free technology achieves the highest part-load efficiencies for chillers and chilled water systems, including water-, air- and evaporatively cooled applications.

Proprietary magnetic bearings replace conventional oil-lubricated bearings, eliminating high friction losses, mechanical wear and high-maintenance oil management systems to deliver chiller energy savings of 35% or more, compared to conventional chillers while ensuring long-term reliability.

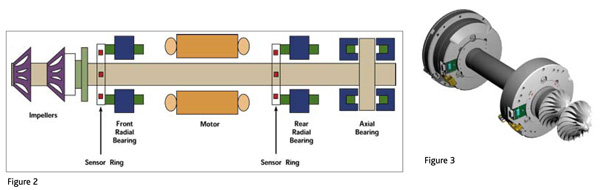

The main moving parts of a compressor – rotor shaft and impellers – are levitated during rotation by a digitally controlled magnetic bearing system. Position sensors at each magnetic bearing provide real-time feedback to the bearing control system, 120 times each revolution, ensuring constantly centred rotation. (See figures 2 and 3)

High-speed variable-frequency operation affords outstanding part-load efficiency, compactness and extraordinary soft-start capacity.

An inlet guide vane assembly trims low-load capacity and is digitally integrated with the variable-speed control to optimise energy efficiency and compressor performance throughout the full range of load and temperature conditions.

In addition, HFC-134a refrigerant cools electronic and electromechanical components to assure maximum efficiency and safe operation.

Run 100% oil-free with magnetic bearings

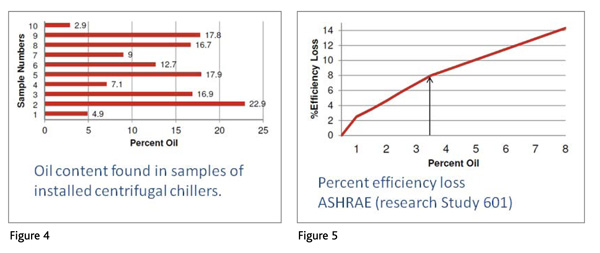

Conventional compressors and chillers consume more energy due to the presence of lubricating oil that hinders heat transfer. Even a chiller with an oil content of 3.5% may lose eight per cent efficiency (See Figure 4). Many chillers are overcharged with oil, resulting in actual energy efficiency much lower than the equipment’s rating (See Figure 5). As against this, friction-free magnetic bearings eliminate the cost of such inefficiencies, as well as the maintenance costs associated with oil service.

The compressor uses an integrated variable frequency drive to reduce compressor speed and maximises energy cost savings as the condensing temperature and/or heat load decreases.

Typically, traditional induction motors of this size are in the 92% efficiency range. The magnetic bearing compressor’s permanent magnet DC motor provides an efficiency of up to 97%, while at the same time eliminating the need for an energy-consuming gear set. The frequency variation of 300 to 800 HZ provides operation compressor speed between approximately 20,000 and 48,000 rpm. In this range, the compressor can generate steeples load.

The magnetic bearings that avoid friction have over 500 times less frictional losses than conventional bearings and, in combination with VFD, reduce the starting current to below 5A. The combination of permanent magnetic motor with VFD and magnetic bearing in the compressor and chiller design elements like electronic expansion valves, innovative flooded heat exchange technology with specially finned tubes and highly intelligent control systems make this technology highly efficient.

A winning combination

Combining these new technologies of magnetic bearings and variable speed drives with HFC refrigerants in a chiller implies that there is typically 32% improvement in the IPLV efficiency. This translates into 50% savings – a considerable year round savings compared with older lubricated reciprocating, screw, scroll or centrifugal chillers. Under AHRI conditions, the IPLV performance can be lower than 0.4 kw per tonne, higher than EER 11.5, while part-load efficiency can be under .25 kW per tonne, higher than EER 13.0.

A further improvement can be achieved by use of the refrigerant HFC-134a for centrifugal chillers. This is the only compound that is being used in equipments in singular compound form. It has no chlorine, does not contribute to ozone depletion and is a highly efficient thermodynamic refrigerant in application.

As a result of stringent testing and applied technology, chiller leak rates are lowered to less than one per cent annually, while existing chillers have a leak rate of 2 to 15%.

HFC 134a also has a smaller molecular mass than the older CFCs and HCFCs. This is an important feature, as it results in an overall product size that is 35 to 40% smaller. This has another effect for replacement issues, as the new system will fit into the space available.

It needs to be noted here that the use of ultra-low Global Warming Potential (GWP) refrigerant HFO -1234ze has already been announced for air-cooled, outdoor mounted chiller applications.

Other advantages

Summary

The oil-free centrifugal technology offers a clear energy and ecological advantage over traditional lubricated chillers. Magnetic bearings and integral variable-speed drives also increase reliability over lubricated machines, and with no oil system to maintain, there is an appreciable drop in maintenance costs. Oil-free centrifugal compressor technology boosts energy efficiency, cuts operating costs and is now well-proven as an alternative worldwide.

The writer is Regional General Manager, Middle East, at Smardt Chiller Group. He can be contacted at philipp.ampferl@smardt.com

Copyright © 2006-2025 - CPI Industry. All rights reserved.