Backed by studies that clearly correlate the effect of indoor air with human health, Mats Sandor, demonstrates why proper ventilation is essential for our wellbeing and how it can be made energy-efficient.

Backed by studies that clearly correlate the effect of indoor air with human health, Mats Sandor, demonstrates why proper ventilation is essential for our wellbeing and how it can be made energy-efficient.

Abstract:

Increased cost of energy, new regulations demanding lower usage of energy and more tight houses make it important to choose the right type of ventilation system. The conflict between energy and good indoor environment lies in the fact that ventilation is necessary to create a good indoor environment; and ventilation needs energy to function. For the future, the key issue is how to reduce the use of energy and, at the same time, improve indoor air quality.

Why ventilation?

The purpose of ventilation is to enable us to breathe clean air by removing stale and polluted air from our homes and replacing it with good quality air. By doing this, we create healthier indoor conditions, leading to better performance and excellent comfort.

As humans, we approximately eat one kilogramme of solid food, drink three kilogrammes of liquid and breathe 15 kilogrammes of air per day per person. We spend around 90% of our time indoors. Yet, we are more concerned about the food and liquid we consume, than the air around us.

Why clean air?

Several studies show that clean indoor air is essential.

The Värmland Study:

The study was started in the year 2000 by Professor Jan Sundell at Denmark Technical University, and Dr Carl-Gustaf Bornehag at the University of Karlstad, and The Swedish National Testing and Research Institute, SP.

All the families in Värmland, who had children between the ages of one and six, received a survey in the mail; a total of 14,000 were sent out. Almost 9,000 of these families responded to the questions asked by the researchers. Within these 9,000 families, there were 11,000 children, making the survey, by far, the biggest study in the world on how the indoor environment affects the health of children.

In order to get more exact results, 400 children (200 healthy, 200 with severe allergies or asthma) were selected for an in-depth study regarding the connection between indoor environment and illness.

So far, the researchers have concluded that ventilation has a significant impact on children’s health. A good air exchange rate does not remove the risk of asthma or allergies, but children living in well- ventilated homes have a better chance of staying healthy. This is an ongoing study with the official name “Dampness in Buildings and Health”.

The Bamse Study:

Another Swedish study pointing in the same direction as the Värmland Study is the Bamse Study. It is a study on children’s allergies carried out in Stockholm. More than 4,000 children from Stockholm, born between 1994 and 1996, were followed from birth. The Bamse Study is a cooperative initiative between The Department of Occupational and Environmental Health, The Astrid Lindgren’s Children’s Hospital and the Institute for Environmental Medicine at Karolinska Institute. The children and their living environment were checked regularly. In the Bamse Study, the researchers concluded, among other things, the following:

Among the children exposed to two or three risk factors (tobacco smoke, poor indoor climate, prematurely interrupted breast feeding), the risk of developing asthma was more than twice, compared to children exposed to one, or none of these risks.

At the age of four, 40% of the children had some form of allergic problem, ie asthma, skin rashes, hay fever or food allergies.

A look at low-energy ventilation

Some of the factors contributing to low power consumption in ventilation system are:

Some of the factors contributing to low power consumption in ventilation system are:

Energy-efficient fans:

EC-fans have a typical saving potential of 20% to 50% compared to AC-fans.

Low pressure drop:

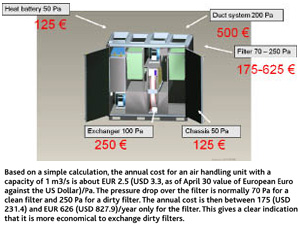

Pressure drop in ventilation systems and ventilation products are important for the overall energy consumption.

Modern ventilation systems have low velocities in the duct system, as well as few on none dampers.

Operating point:

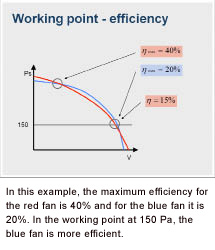

It is crucial that the fan in a system is operating near or at the optimum operating point. It is a mistake to only look at a fan’s highest efficiency. Modern fans are specially designed to have high efficiency at the designed operating point. This is particularly evident for fans designed for low pressure systems.

Demand control ventilation:

With demand control ventilation, the ventilation is only used when necessary and with the right amount. The ventilation could be controlled by temperature, humidity, carbon dioxide and occupancy sensors, timers or manually. Examples of applications are:

Other options

Heat or energy recovering:

Heat or energy recovering:

With a recovering system, the savings are normally essential. Typical recovering is between 50% and 90% of the energy in the transported air.

Building management system:

It is possible to optimise the system to be highly energy efficient and ensure its functionality with a building management system.

Energy efficient fans – European Regulation ErP No 327/2011:

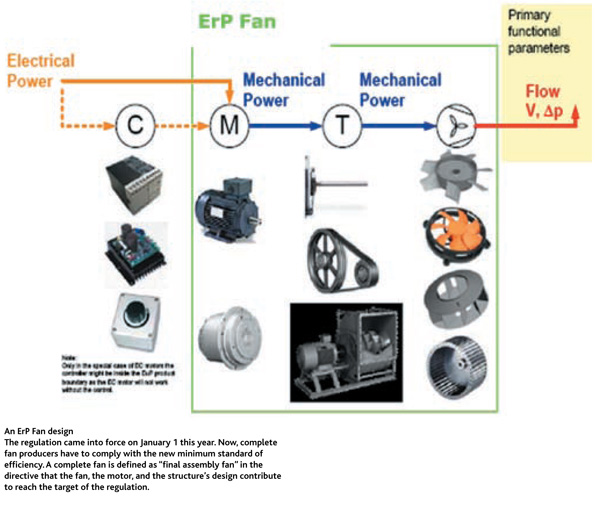

ErP is an abbreviation for Energy Related Products Directive. The objective of the directive is to reduce electrical energy consumption and to force the market to use low-energy consumption components. Less energy consumption means less pollution and, consequently, a cleaner and more sustainable world.

By regulation, EU 327/2011 fans driven by electric motors are classified as widely diffused electric consumption devices that need an Eco-design regulation.

The fan component is classified as part of an electric fan (as “not final assembly”) with reference to regulation EU 327/2011. Also, when the fan is coupled to an electric motor inside a product (machine different from the fan) which is not a ventilator, the fan has to be ErP compliant. The regulation states conditions and equations to measure calculate and certify the fan in regard to the minimum efficiency target.

REFERENCES:

The writer is Technical Director, Systemair AB. He can be contacted at masa@systemair.se

Venting one’s views…

Andrew Kirton, Sales Director for Middle East, Novenco, believes that the two-pronged approach of regulation and technology can reduce a building’s carbon footprint.

Andrew Kirton, Sales Director for Middle East, Novenco, believes that the two-pronged approach of regulation and technology can reduce a building’s carbon footprint.

The objective of a good ventilation strategy is to provide a balance between energy efficiency and air quality. In Europe, there are strict energy-efficiency ratings (EER) for all electrical equipment, including ventilation fans. All forced ventilation systems require electrical power to operate, with the vast majority of the power required by the supply and extract fans.

Specific fan power (SFP) is a parameter that quantifies the energy efficiency of ventilation systems. It’s a measure of the electrical power that’s needed to drive a fan, or fans, relative to the amount of air that is circulated through the fan(s). It’s not constant for a given fan, but changes with both air flow rate and fan pressure rise.

A well-designed ventilation system should minimise this energy usage and acceptable levels of SFP should be legislated in local guidelines to ensure that the correct quality of equipment is installed.

Recent developments in axial fan technology in Europe have led to the world’s first axial flow fan with an efficiency above 90%. These high-efficiency fans can be used in many applications in new build projects and can also be retrofitted to reduce the running costs on any HVAC equipment, including air handling units, dry air coolers and standard supply and extract ventilation fans, providing an ROI of between one and two years.

Once the ventilation system has been correctly designed to provide an acceptable SFP, the system needs to be operated only at the level required to provide acceptable conditions in the ventilated space. This requires ventilation systems to be provided with speed regulation.

Common ways of providing this are normally with two-speed motors or motors fitted with VSDs (variable speed drives). These will require a control variable to determine the correct operating speed of the system. VSDs provide advantages over two-speed motors, including exactly matching the ventilation rate to the space conditions at all times, resulting in reduced energy consumption and lower fan noise.

Copyright © 2006-2025 - CPI Industry. All rights reserved.