Masood Raza highlights the need for district cooling, while taking cognisance of the challenges & demands

Masood Raza made a presentation on the Tamouh district cooling plant on Al Reem Island, at MEED’s Middle East District Cooling 2010 conference in Abu Dhabi (on September 28). While highlighting the need for district cooling, he also took cognisance of the challenges and demands of serving such a mega project. We bring to you the case study in a nutshell.

Al Reem Island is a natural island, covering an area of 633 hectares (68 million square feet). Earlier called Al Reem Isle Abu Al Shuoom, The Pearl and Emirates Pearl Island, it is located about 600 metres off the coast of Abu Dhabi city. It has now been transformed into a residential, commercial and business project, thanks to being developed separately by Sorouh Real Estate, Reem Investments and Tamouh Investments.

Masood Raza conducted his case study on the 90,000 TR Tamouth district cooling plant under the following heads:

FEATURES OF AL REEM DEVELOPMENT

The total plot area of Al Reem Island is over 8.5 million square metres, with the total GFA for the Al Reem Island being over 20 million square metres. This, as stated earlier, includes, Tamouh, Sorouh, Reem Developers and Capital Investment. The developments are mainly high-rise structures and mixed development, with a focus on residential areas covering over 15 million square meters. The total HVAC capacity requirement for the development is 750,000 TR (connected) and 600,000 TR plant.

NEED FOR DISTRICT COOLING

Making a case for district cooling for mega projects, Raza cites the example of the Al Reem Island to highlight the fact that in such a huge development, even a minor improvement in energy requirement can have a major overall impact. He believes that district cooling is highly energy efficient – about 1kW/TR, instead of 1.7 kW/ TR for air-cooled chillers. Consequently, he argues that the installed cooling plant capacity goes down by 15 to 20% and reduces electrical infrastructure, including generation and distribution. Raza claims that the site-wide electricity reduction is about 40%

Arguing that district cooling reconciles the need for fast-paced development to the control on the waste of resources, points out that a developer, thus reaps benefits like, stable chilled water temperature, no chiller noise in buildings, reduced building maintenance cost, more secure supply of chilled water, more spare capacity readily available and more space within buildings. In short, Raza believes that it is a win-win situation, as it is beneficial to the customer, developer, the district cooling provider and for the society at large.

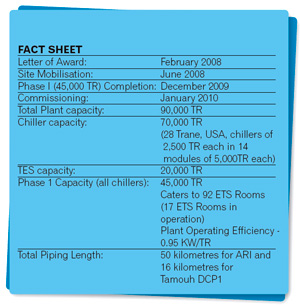

Speaking specifically about the Tamouh plant, Raza provides the following insights:

CHALLENGES AND OPTIONS

Raza, of course, admits that projects of the magnitude of Al Reem Island are not without their attendant teething trouble. He lists the following challenges with regard to shifting load demand:

Raza says that several options were considered for shifting load demand. To keep changing piping design to match the shifting load was one of them. This is evidently not possible after a certain stage. The second option examined was to resort to creating an expensive ring around the main system of piping design. This was deemed difficult for a project like the Al Reem Island. Enforcing a freeze on HVAC demand (for a plot) on all plot developers was also under consideration. Finally, according to Raza, in a stroke of innovative thinking, a mix of all of the above options was exercised.

Network-related challenges:

Plant-related challenges:

CONDENSATE COLLECTION FOR CT MAKEUP

Raza explains that condensate drain collection system can provide eight to 12% during peak flow requirement. However, during off-peak humid conditions, this percentage can be even higher. According to Raza, PAL is in the process of carrying out a practical study to verify the calculated data for condensate recovery to come to definitive conclusions.

He believes that the payback for the investment in the condensate-recovery system is about two to three years at design conditions. However, he is quick to add that this is based on estimates and needs to be further verified, factoring in ground realities.

PROJECT FINANCING

Moving from the technical aspect of a district cooling plant to the financial aspect, Raza maintains that district cooling projects are either financed as BOO (Build Own Operate) or, more typically, BOOT (Build Own Operate Transfer) projects. He believes that BOO/BOOT projects are generally public infrastructure/utilities projects which employ a particular form of structured financing.

Looking at project financing from the lender’s perspective, the hallmarks of BOOT project financing are: the lenders look primarily at the earnings of the project as the source from which loan repayments will be made, says Raza, and adds, their credit assessment is based on the project, and not on the credit-worthiness of the borrowing entity. Raza believes that typically, the financers are attracted towards a project with a minimum IRR of 10%.

The security taken by the lenders being largely confined to the project assets, as such, project financing is often referred to as “limited recourse” financing because, lenders are given only a limited recourse against the borrower, Raza argues.

He points out that for the Tamouh plant, PAL Technology initiated project financing negotiations before the onset of recession, and the financing was secured within six months. The plant and piping has been financed as project finance with 30 to 70 equity-debt, he explains.

The process was not without its share of problems, he adds. The hurdles the company was forced to negotiate were:

Raza points out that as the project was constructed within the stipulated time, the funds have been released by the lending bank almost as per the timeline agreed with the bank.

IN CONCLUSION …

Raza admits that being involved with the Tamouh project has been a learning experience. He poses a couple of questions, possibly rhetoric.

Raza admits that being involved with the Tamouh project has been a learning experience. He poses a couple of questions, possibly rhetoric.

In conclusion, he says that in such projects, offtake guarantees are needed, as no government back-up is available similar to other long-term infrastructure projects. While thinking aloud about the need for government guarantees for improving private sector involvement in the infrastructure sector, he stresses that the capacity must follow the demand of cooling, even if temporary cooling is required for some time.

Educating the customer about the need for a district cooling plant is important, he says, and emphasises that this must be combined with tangible savings directly to the customer – the benefits need to percolate down to the end-user. Raza believes that this is the biggest challenge that the district cooling industry faces today.

In the final analysis, there is a point where academic analysis needs to intersect practical, real-life situations. In fact, it needs to be a symbiotic relationship, as one aids the other, and, more important, one would be soulless without the other. In this context, Raza strongly believes that case studies and technical research papers based on real operating plants need to be encouraged to increase the relevance of the industry to local conditions.

Masood Raza is Head of Engineering at PAL Technology. He can be contacted at: masood@paltechnology.com.

Copyright © 2006-2025 - CPI Industry. All rights reserved.