With numerous new technologies in air conditioning now available, the question that needs to be addressed is whether the VRF sector can continue to thrive in the Middle East market. Rajiv Pillai finds out where VRF systems stand and where they are heading. Energy security in the Middle East has always been a matter of […]

With numerous new technologies in air conditioning now available, the question that needs to be addressed is whether the VRF sector can continue to thrive in the Middle East market. Rajiv Pillai finds out where VRF systems stand and where they are heading.

Energy security in the Middle East has always been a matter of concern. Following Dubai’s successful bid to win the EXPO 2020 and Qatar poised to host the 2022 FIFA World Cup, several infrastructure- and industry-related projects have swung into motion, attracting more people to the region. The frenetic pace of economic activities and growth in population, however, have begun to put tremendous pressure on the region’s energy supply. Besides the market acknowledging the need for energy conservation, there is a conscious push by the UAE government in the direction, with the Dubai Supreme Council of Energy launching the Dubai Integrated Energy Strategy 2030 in 2011, which aims to reduce energy demand by 30% by 2030. To cap this energy demand and to encourage people to use energy-efficient products, HVAC manufacturers in the region have intensified their drive to promote the variable refrigerant flow technology or VRF – a technology reportedly known for its flexibility, modularity, efficiency and suitability.

Industry experts suggest that the VRF market is growing at a pace of 10%-15%, and is worth approximately USD 10 billion, globally. In the Middle East, more and more consultants and building owners are reportedly leaning towards the VRF technology than ever before, as it offers flexibility, energy efficiency and compact footprint. “As the region improves from the recent economic recession, projects are opening up in a big way, which represents a great economic opportunity for this technology,” says Mustafah Abdul Jabbar, Mechanical Engineer at Royal Cool. “Currently, VRF technology has an approximate six per cent of the market share in the Middle East, and the demand is increasing.”

Touted as a high-performance HVAC technology, VRF was invented in Japan more than 20 years ago and has large installed bases in several countries. It is, however, a relative newcomer to the US and Middle East markets. “VRF is a new generation alternative to the fixed-based system this country (UAE) was using, and it came late to this market,” says Zakir Ahmed, Managing Director of NIA, the exclusive agent for Gree products. He explains: “It took time to come to the Gulf countries, because the inverter systems that were used in the VRFs could not handle the high-ambient conditions. That was the technology then, but they have improved the machines; they have improved the protection for the inverter systems, which can withstand high-ambient temperatures of 52 degrees C.”

Other than the claims from industry experts, General Services Administration’s (GSA – an independent agency of the United States Government) Green Proving Ground (GPG) programme assessed the technology and found that VRF systems can achieve 34% and higher HVAC energy cost savings. GPG commissioned researchers at the Pacific Northwest National Laboratory (PNNL) to evaluate the technology. PNNL’s evaluation was based largely on a critical survey of the available VRF literature and discussions with industry experts. Researchers also reportedly took into consideration a partial VRF installation at GSA’s Moakley Federal Court House in Boston, Massachusetts, four additional installations in the Pacific Northwest, a review of VRF simulation work, a hypothetical application of the technology to selected parts of the GSA portfolio, and a lifecycle cost analysis (LCCA) that compares VRF technology with a Variable Air Volume (VAV) system with electric reheat. PNNL’s evaluation indicated that VRF technology merits GSA’s findings and assessment.1

Demand and supply

Jabbar enumerates several reasons for the growing demand for VRFs: Their high efficiency; a need perceived by the market and governments for energy-saving products with environmentally friendly refrigerants; the ongoing advertisement campaigns and training sessions conducted by suppliers and manufacturers for the region; and the use of DC compressors, especially for markets with electricity shortage, such as in Iraq.

“VRF system is going to be one of the players of the market competing against the chillers and standalone systems, naturally because of their energy efficiency,” agrees Kandasamy Anbalagan, Managing Partner at Proleed Engineering Consultants.

Ahmed corroborates this view, suggesting that VRF is about energy conservation and better quality comfort – a normal air conditioner would swing in the temperature range by two degrees C. For VRFs, it is supposed to be half a degree C. Furthermore, he believes that VRF systems have the ability to control the functioning of the air conditioning unit based on real demand, which means for every room there can be a single control. Energy use can, thereby, be rationalised based on actual use, rather than through the forced switching on and off of the machine. All these factors, concur industry experts, have increased the demand for VRF systems.

Roadblocks

Despite the demand, there is a general belief that VRFs could have a much larger market share in the region, provided there is greater clarity on issues related to piping length, fresh air and performance, as well as independently reviewed operational data. Jabbar and Patrick Crombez, Department Manager of Direct Expansion AC Department at Daikin Europe NV – Brussels, admit to some challenges plaguing the VRF industry. Says Crombez: “Fresh air is one of the items we have been tackling. There is also the issue concerning controls integration, especially for BMS systems. For BMS companies, VRF is relatively new from their point of view. So there is a lot of discoveries that is happening there.”

There have been concerns raised by consultants, as well, who say that there is no adequate guarantee from VRF manufacturers about their claims of reliability and efficiency. “As a consultant, we need to know the performance of the equipment at 50 degrees C,” says Gella Bharat, Discipline Specialist (HVAC) at Tebodin & Partners. “What we found from our previous experience is that some of the manufacturers, they don’t even give a warranty that their equipment will run at 50 degrees C; they don’t want to give it in writing.”

Anbalagan believes that the sales teams representing the manufacturers are not well-informed and provide contradicting information. “They don’t understand some of the information that is in their own catalogue,” he says.

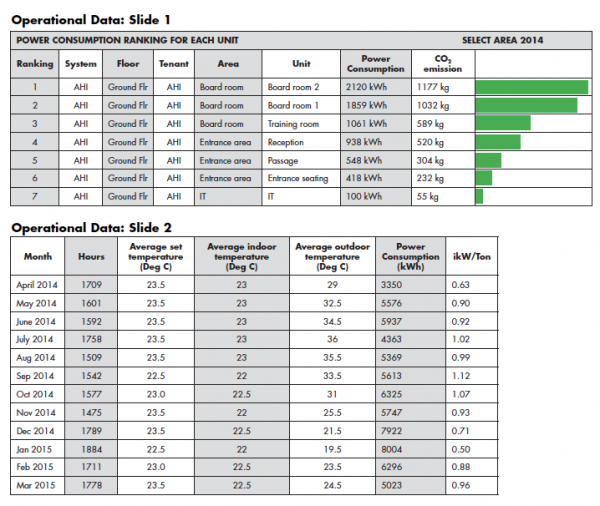

The general concerns range from a lack of awareness about the technology to how to quantify (operational data) and the possibility of refrigerant leaks. These were also the themes discussed at the 3rd Annual Middle East Variable Refrigerants Flow Conference, produced by CPI Industry on March 30 and 31, 2015, in Dubai. Concerning operational data, AHI Carrier, informally representing all the manufacturers, presented real-time operational data (see below) at the conference, which was a first-of-its-kind initiative for the region.

Another issue is that even though the VRV technology allows very long piping distances, due to cost and refrigerant charge limitations in ASHRAE Standard 15, the equipment layout needs to strive to minimise the piping lengths, where possible. “If the system design is done right, you can take them [VRVs] to a higher length of piping,” said Yuji Miyata, the Chairman of Daikin Middle East and Africa, during a conversation with Climate Control Middle East, at their new VRV IV product launch event in Dubai, on June 9.

Dharmesh Sawant, Senior Manager – B2B AC, at LG Electronics Gulf, threw light on the piping issue in his article, titled “Making VRFs work for you”, which appeared in the August 2014 issue of Climate Control Middle East. He stated: “This [piping] issue can be addressed during the design stage by carefully selecting a combination of indoor units and outdoor units. I usually recommend that consultants divide the two systems vertically instead of horizontally. In other words, instead of connecting the entire ground floor to one system and the first floor to another system, it would be better to connect a few of the indoor units of the ground and first floor to one system, and the remaining to another system.”

With the issue of the piping length resolved and operational data presented, it is evident that the VRF industry players are serious in standing their ground and backing their claims.

By the government

A general appeal by industry players is for government bodies to help ease VRF systems into the market. “The government should study what the new technologies are in the HVAC sector, such as in VRFs, and this must be put in the form of a regulation,” says Zoher Abdullah, the Architect at Wafi Engineering Consultancy. “Explaining to the consultant or to the contractor [the benefits of using VRFs] will then be much easier, because there is government backing.”

Ahmed supports this view when he says that VRF systems have been designed with Dubai’s 2030 energy conservation strategy in mind. He elaborates: “The government has to recognise that VRF is a product that has been precisely developed to cut the wastage and also conserve energy. And though the government cannot come and tell end-users that they have to stop using chillers and start using VRFs, it can say that for every square metre of indoor space, end-users will rationalise the energy supply to only so much. If the government were to do such a thing, the customer would go around seeking efficient solutions. VRF is one of them.”

References

1 GSA Website. http://www.gsa.gov/portal/mediaId/196879/fileName/GPG_Findings_06_-_Variable_Refrigerant_Flow.action

| Water-source VRF systems |

At the 3rd Annual Middle East Variable Refrigerants Flow Conference, produced by CPI Industry, publishers of Climate Control Middle East magazine, held on March 30 and 31 in Dubai, Moan Abraham, General Manager, Air-Conditioners, at Hisense Middle East, spoke about the innovative technology of water-source VRF (WS VRF) systems. He said that the advantage of using such a system is that it utilises heat, such as ocean, soil, industrial waste heat and municipal waste water, to realise cooling and heating. It can also be connected to a cooling tower. He claimed that WS VRF offered better efficiency at partial loads, adding that the risk in WS VRFs was reduced with the use of multiple-heat sources, which meant that if one chiller unit failed, the other units would turn on as backup. The following are case studies he presented during the conference:

Pangu Plaza, Beijing

Pangu Plaza, a seven-star condominium, is a famous landmark in Beijing city and the Olympic Centre that has adopted the WS VRF technology. The entire project has an area of 39,360 square metres and has 418,484.70 square metres of construction area. The building, with a height of 191.56 metres, is meant for commercial office purpose, with the other three buildings dedicated to international apartments and one building for a seven-star hotel. The three international apartments have adopted 129 24-HP water source VRF units.

Xiamen Shimao Straits Tower, China

Incorporating office, hotel, loft apartments and retail uses, the 300-metre-tall twin towers, covering a total area of 30,500 square metres and a gross floor area of 338,000 square metres, are installed with 566 water-cooled VRF units.

| The solar VRF system“Gree was the first to launch solar VRF in the GCC,” claims Zakir Ahmed, Managing Director of NIA. He explains that the solar VRF system is a hybrid solar-electric air conditioner that can work on zero power from DEWA. The traditional air conditioner, he says, can consume nearly three times more energy compared to the solar VRF air conditioner, causing the consumer to pay a higher electricity bill.

“There are three key aspects to the product,” Ahmed says, elaborating: “Zero wastage, zero electric charge and zero worry. Considering that renewable energy options are at a premium, the solar VRF system ensures that energy is smartly used and there is absolutely no wastage of energy.” According to Gree, the system incorporates the power management technologies in conversion from DC-to-AC & AC-to-DC with MPPT (Maximum Power Point Tracking), PAWM (Pulse Amplitude-Width Modulation) and ternary communication technologies. This, it explains, is to optimise the power generated from the solar panels and minimise consumption from the grid. |

| WATER AND VRF: View and counter viewPatrick Crombez, Department Manager of Direct Expansion AC Department at Daikin, says: “There is a market for water-source VRF systems in the Middle East as well. It depends a lot on the building. The building dictates what system should be used. If you have a lot of smaller offices, small hotel rooms, lots of variable loads, that’s when a VRV is a better option. If you have steady loads, a chiller would be a better option, to be honest.”

Zakir Ahmed, Managing Director of NIA, says: “Using a body of water as a means of re-cooling condensers was first considered when the Palm Jumeirah Project was under construction. Salinity in sea water presents many challenges for cooling towers. This may not be feasible in the GCC region due to shallow seas and the high temperature of sea water.” |

Copyright © 2006-2025 - CPI Industry. All rights reserved.