HVAC inverter technology dictates the future of energy efficiency in the GCC region, says Nabil Shahin

The need for sustainable solutions around the globe is sparking a crucial change in the heating, ventilation and air conditioning (HVAC) industry, partly through the development and spread of HVAC inverter technology. Although this technology has been available for some time, it is steadily proving to be positive for sustainability in the HVAC sector.

Indeed, this innovation rethinks the standards of energy efficiency and operational optimisation, promising a new era for energy savings and climate control systems. This article will explore the specifics, the current scenario and the potential future impacts of HVAC inverter technology, focusing specifically on the Gulf Cooperation Council (GCC) region.

Understanding HVAC inverter technology

Simply put, HVAC inverter technology is an electronic component that adjusts the frequency of electricity supply to an electric motor using variable frequency drives (VFDs). The component allows the motor to operate at various speeds, rather than running constantly at full speed, resulting in a significant reduction in energy use as well as a more consistent temperature.

Nabil Shahin

Harnessing the power of HVAC inverter technology, a compressor running at partial load significantly enhances the system’s energy efficiency. For instance, consider a 10 TR air conditioning system operating at 50% capacity. The compressor, utilising inverter technology, adjusts its speed to meet this reduced demand. Consequently, while the heat exchanger is engineered to handle the full 10 TR load, it now only needs to cool a 5 TR load. This essentially means that the system is using a larger than necessary heat exchanger for a smaller load, enabling it to cool more efficiently. This adaptation to the system’s cooling demand not only optimises energy usage but also leads to substantial energy savings, epitomising the benefit of inverter technology in terms of energy efficiency.

The technology brings several other benefits, including mechanical and electrical advantages, enhanced user experiences, and increased environmental sustainability for both residential and commercial applications.

Indeed, the scope of HVAC inverter technology has dramatically expanded and is no longer limited to residential applications. It now encompasses various types of HVAC systems, making a mark across the spectrum. From split and unitary systems to variable refrigerant flow (VRF) systems and chillers, inverter technology is being used to boost energy efficiency and operational effectiveness.

Commercial refrigeration has also witnessed the integration of the technology, contributing to substantial energy savings. Water heaters employing heat pumps is another example. This widespread adoption of inverter technology signifies its growing importance across the industry, promising greater efficiency and sustainability in a diverse range of HVAC applications.

Energy savings: The inverter advantage

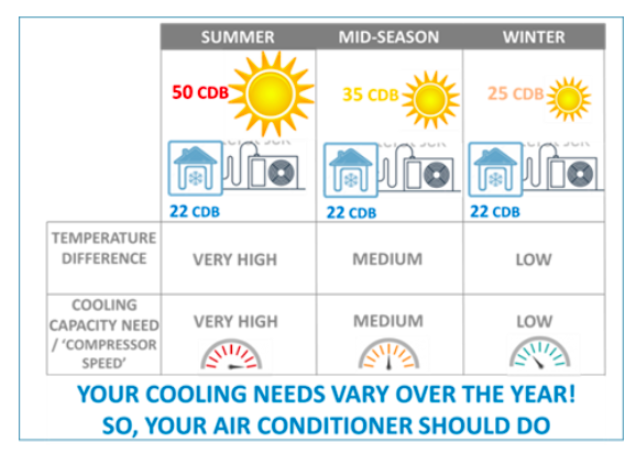

One of the most significant benefits of HVAC inverter technology is the substantial energy savings it can provide. This is primarily achieved by adjusting the compressor’s speed in response to the cooling or heating demand. When the system operates at partial load, the inverter slows down the compressor, thus reducing energy consumption. Conversely, when a full load is required, the compressor’s speed increases to meet the demand, but even then, it does so more efficiently than a conventional HVAC system operating at full capacity. In the case of the inverter mode, the air conditioning system runs to meet partial cooling load (not full-blast cooling load) for most of the cooling season, as opposed to the less efficient on/off cycling. As a result, inverter technology can lead to energy savings of anywhere from 20% to 60%, compared to conventional, non-inverter type systems.

Benefits: Precise control, enhanced comfort

When paired with advanced control technology, inverter air conditioning systems offer remarkable precision in regulating indoor temperature, often to within a fluctuation of a half- to one-degree Celsius, a significant improvement compared to conventional systems, which can exhibit variations of up to five degrees Celsius. This steady temperature control helps avoid situations such as where an occupant might wake up feeling too hot or too cold. Inverter air conditioning systems can also sustain ideal relative humidity levels, typically between 40% and 60%. This capability ensures a healthier and more comfortable indoor atmosphere, a feature especially valuable in regions with extreme climatic conditions.

These systems also operate with less noise, both for the indoor and outdoor units, contributing to a more relaxed living and working environment. Moreover, the efficient operation of inverter technology prevents system components from being overworked. By not constantly running at full load, the motors experience less wear and tear, resulting in a longer lifespan for the unit and less frequent maintenance.

Current market and the regulatory impact

Currently, HVAC systems with inverter technology comprise approximately 25% of units sold in the GCC region market, a percentage that is steadily increasing. In contrast, some regions in Europe and Japan have hit a 100% inverter share in the residential market, thanks to regulatory mandates. Other countries, such as China, are also moving in this direction, with over 70% market share for inverter equipment.

In the GCC region, plans to introduce seasonal energy efficiency methods to measure the efficiency of air conditioning units will likely encourage a shift towards inverter technology, because traditional, fixed-speed air conditioners will not be able to meet these new, higher energy efficiency standards based on the Seasonal Energy Efficiency Ratio (SEER).

The Air-Conditioning, Heating, and Refrigeration Institute (AHRI), through its recently established MENA standards technical committees, is making strides toward developing customised standards for this equipment. The committees – comprising international and regional manufacturers, regulatory bodies, consultants, test labs and other stakeholders – are collaboratively working on seasonal and integrated energy efficiency ratio calculations and test methods, specifically tailored for regions with high-ambient temperatures. Upon the standards’ revision, they will be submitted to the relevant regulatory bodies for adoption.

What this means for regional manufacturers

Manufacturers in the region need to be prepared for this inevitable shift towards inverter technology. To meet future higher energy efficiency standards, regional manufacturers would be advised to dedicate resources into researching and developing inverter technology.

Another key consideration for manufacturers planning to design inverter-based HVAC equipment for the high-ambient conditions of the GCC region pertains to the cooling of electronic circuit boards, specifically Variable Frequency Drives (VFDs) and processors. It is universally known that heat is a major adversary for electronic components, making it critical to ensure these circuit boards are kept cool during operation, especially for outdoor equipment. Some innovative manufacturers have employed the practice of using refrigerant lines to cool their processors and other essential components. Other effective cooling methods exist, as well.

Best practices and recommendations

To maximise the benefits of HVAC inverter technology, consider these best practices:

Conclusion

The advancement of HVAC inverter technology signals a move towards greater sustainability, efficiency and functionality within the HVAC industry. It is crucial for consumers and industry professionals in the GCC region to stay updated with the latest developments to fully leverage its potential.

Looking forward, superior temperature control, energy efficiency and sustainability through HVAC inverter technology will become the norm. It’s especially vital for manufacturers in the GCC region to prepare for a future where climate control systems better align with the ever-changing environmental and energy standards.

Copyright © 2006-2025 - CPI Industry. All rights reserved.