Dubai seminar focuses on the optimising of hydronic distribution in an HVAC system; the occurrence of fouling in evaporators; and the importance of efficient, correctly sized and commissioned pressure maintenance systems. By our correspondent.

Dubai seminar focuses on the optimising of hydronic distribution in an HVAC system; the occurrence of fouling in evaporators; and the importance of efficient, correctly sized and commissioned pressure maintenance systems. By our correspondent.

TA Hydronics on October 17 conducted a technical seminar in Dubai that highlighted the implications of HVAC system optimisation on global energy consumption and also focused on energy savings in different HVAC system areas individually and at savings across the system as a whole.

Introducing the seminar, Bassam Al Awar, the Managing Director (Middle East, Africa and India) for TA Hydronics, spoke of the company’s three areas of strength, namely pressure maintenance, thermostatic control, and hydronic balancing and control.

Dr Jean-Christophe Carette, the Head of the Hydronic College of TA Hydronics, was the keynote speaker. He led the seminar, in which he addressed energy savings in broad and specific terms; the occurrence of fouling in evaporators; and the importance of efficient, correctly sized and commissioned pressure maintenance systems.

Dr Jean-Christophe Carette, the Head of the Hydronic College of TA Hydronics, was the keynote speaker. He led the seminar, in which he addressed energy savings in broad and specific terms; the occurrence of fouling in evaporators; and the importance of efficient, correctly sized and commissioned pressure maintenance systems.

Saying that 40% of the world’s energy consumption was used in buildings and that 50% of that was by HVAC systems, Dr Carette added that there were different approaches to shave the consumption. Insulation and double glazing represented one approach and could lead to larger energy savings, but the payback period was very long, Dr Carette said. On the other hand, he added, the use of new technologies and system approach of hydronic design constituted an appealing option and came with a shorter payback time. A third approach, he said, was to avoid human interference with sophisticated systems, which included continuous educating of tenants in a facility. “All three areas are interconnected, though,” Dr Carette said. “You cannot hope to achieve with only one.”

If the first two approaches were to be adopted, he said, the building modification required adaptation or modernisation of the HVAC installation to take into consideration heat gain or loss. And if the second and third approaches were to be adopted, when modifying an HVAC installation, one must take into account the capability of optimising a building HVAC system (optimising the hydronic distribution in the HVAC system) to reduce its energy consumption by 30%, he said. That, he added, would depend on the type of building, though.

Speaking on the issue of fouling in evaporators, Dr Carette said that whenever there was talk on energy efficiency, fouling was not something that came up for discussion, though it was important. Elaborating on micro-fouling – scaling, corrosion fouling and particulate fouling – Dr Carette spoke of the issue of improper pressurisation loads. “If you don’t do pressurisation right, you create an engine for corrosion,” he said.

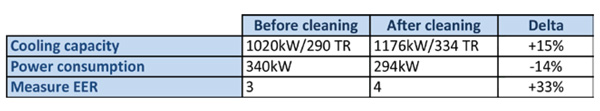

Giving an example of an apartment (with nominal power consumption of 280kW) in Nanjing, China, Dr Carette demonstrated the effect of fouling on performance, with a before-cleaning and after-cleaning comparison.

Dr Carette, then, elaborated on how fouling in evaporators also affected the pressure drop of the evaporator, owing to a reduction of cross-section due to thickness of deposit layer and to an increase of surface roughness.

Speaking, then, on the importance of efficient, correctly sized and commissioned pressure maintenance system, he said it could not be over-emphasised.

Saying that there was energy saving in a hydronic distribution regime, Dr Carette highlighted how pumping costs represented the main energy cost in hydronic distribution. To that effect, he said, it was important to target a minimising of pumping costs. Solutions would be, he said, to take advantage of the latest pump technology (electronic variation, synchronous motor) and to select pumps so that they operated in their optimum efficiency area.

Another way to save costs in hydronic distribution would be to work with the flow, Dr Carette said. It was important to obtain a variable flow installation correctly adjusted inflow. Also, he added, it was important to reduce the required pump head by design.

Carett Speak

|

Copyright © 2006-2025 - CPI Industry. All rights reserved.