CFD analysis in 10-month-long study reveals fabric duct is 24.5% more efficient than metal.

CFD analysis in 10-month-long study reveals fabric duct is 24.5% more efficient than metal.

Mechanical engineers always suspected that fabric HVAC ductwork is more energy efficient than its metal duct counterpart, but now three members of the Iowa State University’s Mechanical Engineering Department have proven a 24.5% efficiency differential.

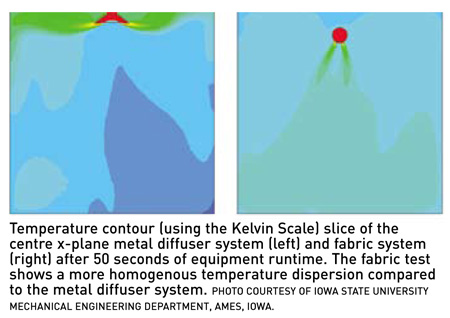

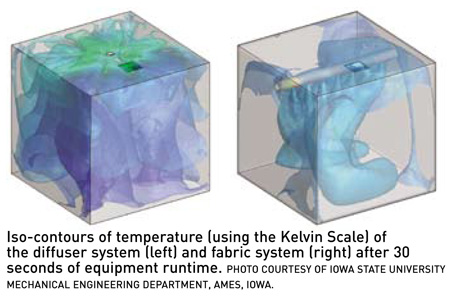

The 10-month-long study, “Thermal Comparison Between Ceiling Diffusers and Fabric Ductwork Diffusers for Green Buildings”, proved fabric duct heats rooms faster and more uniformly to satisfy temperature set points versus metal duct/diffusers, which results in reduced mechanical equipment runtime, thus saving energy in the process.

“This is a monumental study for consulting engineers needing proof their fabric air dispersion specifications are green for sustainable building and LEED projects,” said Cary Pinkalla, president of DuctSox, Peosta, Iowa, a fabric duct designer and manufacturer. “We knew fabric duct was more efficient, simply from the feedback of occupants who experience better indoor air comfort, but 24.5% more efficiency is an incredible discovery.”

The study used computation fluid dynamics (CFD) analytics in an 8 x 8 x 8-foot room with a ceiling-mounted return air vent, which is a typical commercial office space heating configuration. CFD modeling analysed the airflow of a typical 1 x 1-foot metal ceiling supply fixture with a four-way diffusion pattern, then compared it to the performance of an eight-foot-long, six-inch-diameter ceiling-suspended fabric supply duct with seven pairs of one-inch-diameter air dispersion orifices spaced one-foot apart.

“Ductwork system efficiency tends to take a secondary importance to mechanical equipment efficiencies in project specifications, therefore we have now provided engineers with the data that will make air distribution more efficient as well,” said Michael G. Olsen, Ph.D, an associate professor of mechanical engineering, who conducted the project along with Baskar Ganapathysubramanian, Ph.D., assistant professor and Ph.D candidate/graduate assistant, Anthony Fontanini.

While various post-study phases are still being completed, the authors are certain of a slim ±2.5% margin of error and that the same 24.5% efficiency can be achieved in larger spaces such as big box retailers, warehouses and other commercial/industrial buildings.

The study is now available free at www3.me.iastate.edu/bglab. It has also been published in Energy and Building Magazine, New York, an international journal of research applied to energy efficiency in the built environment.

Copyright © 2006-2025 - CPI Industry. All rights reserved.