The importance of sealing and cleaning of HVAC ductwork to mitigate energy loss, increase equipment life and improve IAQ cannot be overstated. John Guthrie elaborates

The importance of sealing and cleaning of HVAC ductwork to mitigate energy loss, increase equipment life and improve IAQ cannot be overstated. John Guthrie elaborates …

According to the US Department of Energy, the typical duct system loses 25 to 40% of its energy output due to improper sealing and air leakage through small cracks and seams. The result is higher utility bills, poor indoor air quality and ruined insulation. Duct sealing is one of the most significant energy-efficiency improvements that can be performed on a building retrofit or new construction. Proper sealing benefits include energy savings, reduction of heating and cooling cost, improved building durability and a healthier indoor environment.

Exterior insulated ductwork that has not been sealed properly is found to produce air gaps that can introduce moisture into the ductwork, allowing the insulation to become water logged and lose its insulating value. These air gaps can also completely destroy the insulation, causing need for a costly replacement. Spraying sealant on the inside of bare metal ductwork prevents moisture and leaks as well as insulation deterioration.

A number of things inside ductwork may adversely affect the indoor air quality of a facility. The breakdown of fibreglass insulation that is not properly encapsulated results in fibre build-up inside ductwork. Mould and bacteria can feed on particulate matter that accumulates in corners and on fire and smoke dampers. Dirt and debris continue to accumulate if the optimal airflow through ductwork is not achieved. Poor air quality may result in health problems for those who reside or work in the building. In spite of these issues, many facilities go years without having their ducts cleaned due to the difficulty of the task. Over the past few years, however, novel solutions for improving indoor air quality by cleaning and properly sealing HVAC ductwork have been developed, bringing duct cleaning into the 21st century.

A number of things inside ductwork may adversely affect the indoor air quality of a facility. The breakdown of fibreglass insulation that is not properly encapsulated results in fibre build-up inside ductwork. Mould and bacteria can feed on particulate matter that accumulates in corners and on fire and smoke dampers. Dirt and debris continue to accumulate if the optimal airflow through ductwork is not achieved. Poor air quality may result in health problems for those who reside or work in the building. In spite of these issues, many facilities go years without having their ducts cleaned due to the difficulty of the task. Over the past few years, however, novel solutions for improving indoor air quality by cleaning and properly sealing HVAC ductwork have been developed, bringing duct cleaning into the 21st century.

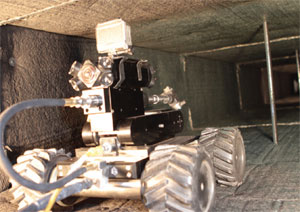

Robotic cleaning and sealing solutions can help improve indoor air quality and decrease heating and cooling costs without significant interruption to building occupants. Plus the sealants and encapsulants the robotic cleaning and sealing solutions use are typically anti-microbial, meaning they do not provide a food source for bacteria.

High-performance, robotically applied insulation encapsulants are designed for use inside HVAC ductwork. At 13 g/l (grams per litre), these very low-VOC coatings are ideal for critical projects, such as hospitals and schools. A semi-gloss finish can provide a surface that will prevent debris accumulation, which could lead to mould growth. Water-based, robotically applied, spray sealants are now engineered to seal joints and seams from the inside of the HVAC ductwork. The superior physical properties of these sealants can meet and exceed SMACNA pressure classes, while their flexibility allows for system vibration without cracking.

Ducts are rarely inspected inch-by-inch, making it possible for breaches in the system to exist. Such breaches may include poor or non-existent sealing, improperly installed turning vanes, or full duct separation, resulting in compromised airflow. Robotic cleaning and sealing solutions make it possible to inspect for debris that has built up on the coils in VAV boxes. Any of these issues will result in an inefficient HVAC system, creating unnecessary additional monthly operational costs. The only way to ensure that these problems do not adversely affect the efficiency of the HVAC system is to visually inspect them. Robotic systems are frequently equipped with an integrated digital video recorder, which combined with the included personal computer software, creates a powerful inspection and documentation tool.

Remotely operated vehicles can be equipped with a variety of payloads, depending on the object of their mission. For instance, they might be equipped with a pneumatic cleaning attachment to remove particulate from the ductwork. In addition, an airless spray attachment can allow the ductwork to be sealed or fibreglass insulation to be encapsulated. These kits are equipped with quick disconnect hardware for speedy attachment and set-up. Once deployed, such systems are controlled remotely, and their progress can be monitored on an LCD display using a live video feed. Upon reaching an area in need of remediation, a cleaning robot gets to work, cleaning with air-driven whips or brushes, or sealing leaks and coating damaged insulation with an airless sprayer. Some attachments are capable of 360-degree rotation, ensuring that every inch of ductwork that requires attention is treated properly.

Remotely operated vehicles can be equipped with a variety of payloads, depending on the object of their mission. For instance, they might be equipped with a pneumatic cleaning attachment to remove particulate from the ductwork. In addition, an airless spray attachment can allow the ductwork to be sealed or fibreglass insulation to be encapsulated. These kits are equipped with quick disconnect hardware for speedy attachment and set-up. Once deployed, such systems are controlled remotely, and their progress can be monitored on an LCD display using a live video feed. Upon reaching an area in need of remediation, a cleaning robot gets to work, cleaning with air-driven whips or brushes, or sealing leaks and coating damaged insulation with an airless sprayer. Some attachments are capable of 360-degree rotation, ensuring that every inch of ductwork that requires attention is treated properly.

Robotic cleaning systems are capable of hard-to-reach remediation that would otherwise result in much more costly renovations. The energy efficiency of an HVAC system is contingent upon it remaining free of leaks and debris. Cleaning robots help to mitigate energy loss by fully cleaning and properly sealing ductwork, resulting in increased airflow and reduced operational costs. They can also dramatically improve a building’s indoor air quality, purging the system of long-unnoticed particulate.

Copyright © 2006-2025 - CPI Industry. All rights reserved.