In this third and final part, Thomas Blewitt concludes his review of the current status of standards and codes relevant to flammable refrigerants.

In this third and final part, Thomas Blewitt concludes his review of the current status of standards and codes relevant to flammable refrigerants. He points out that as the drive towards more environmentally friendly refrigerants and greater energy efficiency gains ground, it is also important for stakeholders of the US safety system to take a holistic look at the potential impact of such use, and take steps to ensure the continued safety track record of HVAC equipment and appliances.

Refrigerant standards

ANSI/ASHRAE Standard 34, designation and safety classification of refrigerants

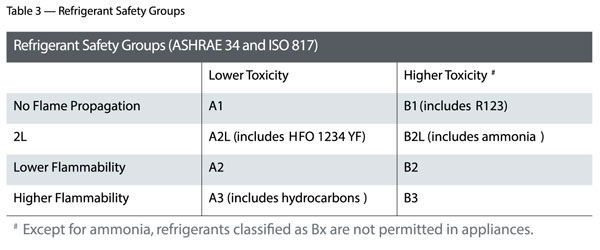

According to the standard, “ASHRAE Standard 34-2010 is intended to establish a simple means of referring to common refrigerants instead of using the chemical name, formula, or trade name. It establishes a uniform system for assigning reference numbers, safety classifications, and refrigerant concentration limits to refrigerants.”34 Most notable in the context of this paper is the ASHRAE 34 designation of HC refrigerants as A3 – high flammability, lower toxicity (see Table 3 for illustration of classification scheme).

According to the standard, “ASHRAE Standard 34-2010 is intended to establish a simple means of referring to common refrigerants instead of using the chemical name, formula, or trade name. It establishes a uniform system for assigning reference numbers, safety classifications, and refrigerant concentration limits to refrigerants.”34 Most notable in the context of this paper is the ASHRAE 34 designation of HC refrigerants as A3 – high flammability, lower toxicity (see Table 3 for illustration of classification scheme).

A significant inclusion in the latest edition (Clause 6.1.3) is the optional 2L subclass added to the existing Class 2 flammability classification, signifying Class 2 refrigerants with a burning velocity less than or equal to 10 cm/s. Class 2L refrigerants include R32 and the newer HFO 1234 yf, which is being promoted for use in motor vehicles.

The potential market for 2L refrigerants in HVAC equipment and appliances is currently unknown and further equipment standards development is needed. Otherwise, a 2L refrigerant will simply be handled as a Class 2 (eg, A2) refrigerant. Proprietary studies done to date have suggested that equipment and installation requirements that result in ignition sources being kept a distance above the floor (or not directly below wall mounted equipment) may facilitate introduction of such refrigerants.

ANSI/UL 2182, standard for safety for refrigerants

This standard contains test procedures and methods to evaluate refrigerants and to authoritatively mark containers according to the extent of the refrigerant’s flammability. The refrigerants covered in this standard are those used as components of air conditioning and refrigeration equipment.35 The standard was created in 1994 as a supplement to ASHRAE 34, and is intended for use in conjunction with end product appliance standards. It enables the characterisation of flammable refrigerants (blends, in particular) with respect to fractionalisation, flammability and auto-ignition. The requirements do not yet address the additional characterisation needed for Type 2L refrigerants.

ANSI/NFPA 58, liquefied petroleum gas code

This code applies to the storage, handling, transportation and use of LP-Gas. It indicates that “refrigeration cycle equipment and LP-Gas used as a refrigerant in a closed cycle” is outside the scope of the code.36 However, the 2008 Handbook for NFPA 58 states that the scope exclusion for refrigerant cycle equipment does not include the storage of LP-Gas, which would include gas in cylinders such as may be used by service personnel. For small HVAC and appliances, the cylinders are likely to be DOT cylinders.37

It would seem likely that the well-established practice for handling LP-Gas cylinders used in barbeques and similar applications would be appropriate for the filling, transport and storage of cylinders used for servicing household and smaller commercial HVAC equipment and appliances. However, NFPA 58 does not specifically anticipate refrigerant recovery/recharge in clause 6.2.2, where it lists applications where containers may be brought into buildings, nor in clause 6.19 where specific uses are cited. Temporary use for training and demonstration purposes (clause 6.19.9) is limited to 20 lbs. of propane in a cylinder, although the cylinder may have a larger capacity.

Equipment standards

ANSI/ASHRAE Standard 15, safety standard for refrigeration systems

ASHRAE Standard 15-2010 is directed towards the safety of persons and property on or near the premises where refrigeration facilities are located.38 While the standard covers installations involving the full range of potential refrigerant charges in equipment, it defers to the listing of equipment complying with appliance safety standards for charges of less than 3 kg, with some restrictions. For example, institutional occupancies are permitted only up to 50% of the refrigerant concentration limit (RCL)39 permitted for other occupancies.

Group A3 and B3 refrigerants are not permitted except where approved by the authority having jurisdiction. One exception to the restriction is “listed portable-unit systems containing no more than 0.331 lb. (150g) of Group A3 refrigerant, provided that the equipment is installed in accordance with the listing and the manufacturer’s installation instructions.”40 This requirement effectively means that self-contained, permanently installed (not “portable”) commercial and large household refrigerators and freezers may employ A3 refrigerants only with permission. Typical household refrigerators, dehumidifiers and other cord and plug connected appliances meeting the charge restriction would be permitted.

ASHRAE 15 includes a general prohibition on the use of Group A2, A3, B1, B2 and B3 refrigerants for comfort cooling (Clause 7.5.2). There is an exception for sealed absorption (ammonia) systems and unit systems (eg, window air conditioner), provided that the refrigerant quantity is no more than 3 kilogrammes or 10 kilogrammes for residential and commercial occupancies, respectively. [Note that ANSI/UL 484 is expected to restrict room air conditioners employing flammable refrigerants to A2 and A3 refrigerants.]

The ASHRAE committee responsible for Standard 15 (SSPC15) continuously maintains the standard and has formed an ad hoc group to address the new 2L refrigerant sub-class created by SSPC34 (committee responsible for ASHRAE 34).

ANSI/UL 207, Standard for safety for refrigerant-containing components and accessories, nonelectrical

These requirements cover non-electrical, refrigerant-containing components and accessories (eg, accumulators, driers, evaporators, condensers, etc.), intended for field installation in accordance with ASHRAE 15 in refrigeration systems, air conditioning equipment, or both, charged with the refrigerants identified for use in the component or accessory. The requirements also apply to components and accessories intended for use by manufacturers in factory-assembled systems or units, in which case the component or accessory is also judged under the requirements for the individual system or unit.41

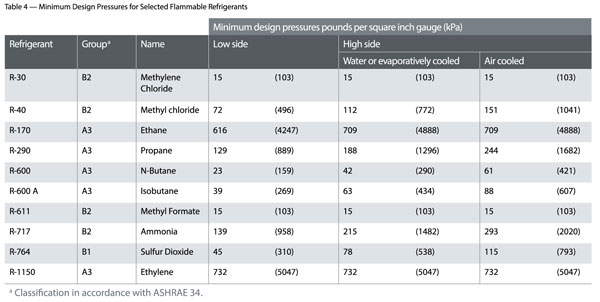

Primarily addressing strength of materials and mechanical assembly, the standard includes consideration of flammable refrigerants. ANSI/UL 207 Table 11 specifies the minimum design pressures for common refrigerants. Data for flammable refrigerants is excerpted from that table and reproduced in Table 4.

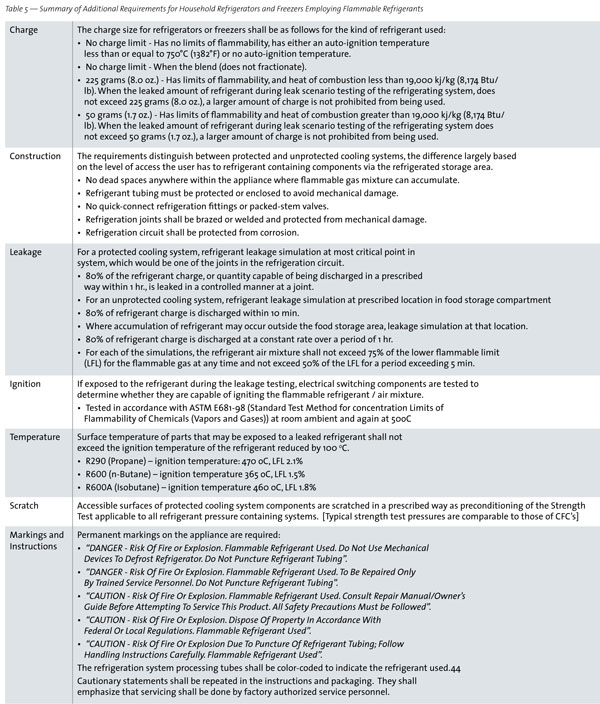

ANSI/UL 250, standard for safety for household refrigerators and freezers

This standard applies to self-contained household refrigerators and freezers for use in residential occupancies in accordance with the National Electrical Code, ANSI/NFPA 70.42 Supplement SA of the standard documents the requirements for refrigerators (freezers, etc) having flammable refrigerants. It addresses concerns regarding the flammability of the refrigerant by limiting the amount of charge according to auto-ignition temperature or heat of combustion, and controlling for design and construction variables that can contribute to the risk of fire. See Table 5 for a summary of the requirements.

ANSI/UL 250 will be superseded in 2016 by ANSI/UL 60335-2-24, the Standard for Household and Similar Electrical Appliances, Part 2: Particular Requirements for Refrigerating Appliances, Ice-Cream Appliances and Ice-Makers.43 With respect to flammable refrigerants, the IEC requirements are modified or replaced such that the requirements are effectively the same as the current ANSI/UL 250 standard.

The scope of ANSI/UL 60335-2-24 is not identical to that of ANSI/UL 250. ANSI/UL 60335-2-24 also includes ice makers and household ice cream makers, which are covered by ANSI/UL 563 (Ice-Makers) and ANSI/UL 621 (Ice-Cream Makers). Should such appliances use flammable refrigerants, ANSI/UL 60335-2-24 would be applicable for that aspect of their design.

ANSI/UL 471, standard for safety for commercial refrigerators and freezers

These requirements cover unitary (self-contained) and remote commercial refrigerators and freezers intended for connection to circuits rated not greater than 600 volts AC. Commercial refrigerators and freezers include equipment, such as display cases, reach-in cabinets, meat cases, frozen food and merchandising cabinets, beverage coolers, beverage cooler-dispensers, food service carts, ice-cream cabinets, soda fountain units, door panel assemblies and processing water coolers.45

Flammable refrigerant requirements of this standard (Supplement SB) are virtually identical to those of ANSI/ UL 250, with the notable exception of a higher allowable refrigerant charge and the particulars of required markings and instructions. Clause SB3.3 of the standard limits flammable refrigerant charge as follows:

The current standard further indicates that, when the leaked amount of refrigerant during leak scenario testing of the refrigerating system does not exceed the 225 or 150g value, a larger amount of charge would not be prohibited from being used.

ANSI/UL 1995, standard for safety for heating and cooling equipment

The standard is applicable to stationary equipment for use in nonhazardous locations rated 7200 V or less, single- or three-phase, and remote control assemblies for such equipment. Cooling equipment examples include heat pumps, air conditioners, liquid chillers, condensing units, heat pump water heaters and fan coil units.46 Currently, the standard does not address the subject of flammable refrigerants, which should be construed to mean that flammable refrigerants (aside from ammonia47) are not permitted – an interpretation consistent with ASHRAE Standard 15.

There is an active, tri-national harmonisation effort being conducted under the auspices of the Council for the Harmonization of Electrotechnical Standards of the Nations of the Americas (CANENA)48 to update parts of ANSI/UL 1995 (and completely replace UL 484 and UL 474) with a standard based on IEC 60335-2-40, Standard for Household and Similar Electrical Appliances, Part 2: Particular Requirements for Electrical Heat Pumps, Air Conditioners and Dehumidifiers. Draft UL 60335-2-40 deals with the safety of electric heat pumps, including sanitary hot water heat pumps, air conditioners, and dehumidifiers incorporating motor compressors and hydronic room fan coils.

Though the IEC standard also addresses electric heat pumps, air conditioners and dehumidifiers containing flammable refrigerant, the Standards Technical Panel developing the draft standard has not itself addressed flammable refrigerants in its work. For this reason, the draft UL standard has a US national deviation that would currently preclude use of flammable refrigerants.

IEC 60335-2-40 uses the ASHRAE 34 refrigerant classification system (also used in ISO equivalent standard, ISO 817). For mechanical strength of the refrigeration system, the standard refers to ISO 5149 requirements.49 Many of the construction requirements for equipment employing flammable refrigerants are similar to those described for ANSI/UL 250, with the addition of specific construction requirements for equipment charged at the installation site, and of requirements addressing transport, storage and service operations. The most significant difference between the standards involves how charge limits are determined.

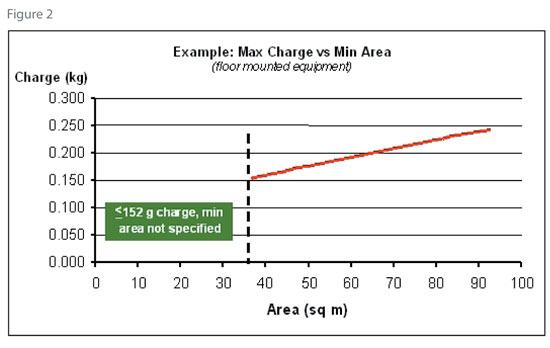

Rather than a fixed charge limit, IEC 60335-2-40 correlates refrigerant charge, volume of the space (room) for equipment installed indoors, and installation height (floor, wall, window, ceiling). Smaller amounts (eg, ≤152 g propane) of flammable refrigerant in products, such as portable dehumidifiers are addressed in a manner similar to that of a refrigerator (minimum room size not specified, mechanical ventilation not required).

For more than these amounts (eg 152 < g ≤ 988 propane), the equipment must be marked with a minimum room size, calculated in accordance with Annex GG of the standard (see Figure 2 for example results). This requirement will typically affect portable air conditioners. Larger amounts (up to 4.94 kilogrammes) of refrigerant will require mechanical ventilation operated by a leak detector/sensor. These amounts are limited to fixed equipment only.

Equipment having very large amounts of refrigerant is not covered by IEC 60335-2-40, which states that national standards shall apply (eg, ASHRAE 15).

ANSI/UL 484, standard for safety for heating and cooling equipment

These requirements cover room air conditioners rated not more than 600 Vac. Room air conditioners include packaged terminals (PTACs), special purpose and recreational vehicle type air conditioners.

Flammable refrigerant requirements have recently achieved consensus in the UL 484 Standards Technical Panel and will be published shortly. These requirements are similar to the requirements described above for IEC 60335-2-40, in that the maximum charge is correlated to the size of the room in which the air conditioner is intended to be installed. However, they do not include an allowance for larger amounts of flammable refrigerant when there is mechanical ventilation.

ANSI/UL 474, standard for safety for heating and cooling equipment

This standard details requirements for movable, household, self-contained dehumidifiers employing hermetic refrigerant motor-compressors, and intended for connection to single-phase, alternating-current circuits rated not more than 20 A, 125 V or 15 A, 208 or 230 V. The situation relative to flammable refrigerants is identical to that of ANSI/UL 484.

UL 984, standard for safety for refrigerant motor compressors

This is the legacy standard applicable to hermetic refrigerant motor-compressors rated 7200 V or less, for use in air conditioning and refrigerating equipment that comply with the standards applicable to such equipment.It distinguishes between refrigerants primarily by their thermodynamic properties, and by the strength of materials necessary to contain the refrigerants under normal and abnormal conditions. Specific reference to flammable refrigerants is not made in the standard; instead, it defers to ASHRAE 15.

The basic requirements are the same for all types of refrigerants, except that leakage around gaskets and seals is not permitted during Strength

Testing of compressors intended for refrigerants other than A1 (or A1/A1 blends). The flammable refrigerant, lubrication and the compressor motor electrical insulating system must also be compatible. The standard prescribes a test to establish compatibility, though there are alternative means to do so.

Going forward, UL 984 will only cover motor-compressors that are outside the scope of ANSI/UL 60335-2-34.

ANSI/UL 60335-2-34, standard for household and similar electrical appliances, part 2: particular requirements for motor-compressors

In late 2009, revisions to the previously published UL 60335-2-34 were completed so that the standard could be declared as harmonised with UL 984. Designation as an American National Standard (ANS) was then transferred from UL 984 to UL 60335-2-34.

ANSI/UL60335-2-34 is based on IEC 60335-2-34 whose scope “deals with the safety of sealed (hermetic and semi-hermetic type) motor-compressors, their protection and control systems, if any, which are intended for use in equipment for household and similar purposes and which conform with the standards applicable to such equipment.

It applies to motor-compressors tested separately, under the most severe conditions which may be expected to occur in normal use, their rated voltage being not more than 250 V for single-phase motor-compressors and 480 V for other motor-compressors.”51

There is no difference between ANSI/UL 60335-2-34 and UL 984 with regard to how refrigerants are handled.

Other appliance standards

Other standards potentially affected by the introduction of flammable refrigerants are ANSI/UL 412, Standard for Safety for Refrigeration Unit Coolers, ANSI/UL 399, Standard for Safety for Drinking Water Coolers,52 and ANSI/UL 541, Standard for Safety for Refrigerated Vending Machines.

“Reverse-cycle” heating, long the staple of heat pumps, is also making an appearance in products such as clothes dryers and water heaters. With their experience in the use of HC refrigerants in household refrigerators and freezers, European manufacturers have expanded the application to these newer energy saving technologies (eg, clothes dryers53).

The water heater application is currently covered by ANSI/UL 1995 for conventional refrigerants. There is no current mechanism within that standard to address a flammable refrigerant. Similarly, clothes dryer requirements (ANSI/UL 2158, Standard for Electric Clothes Dryers) do not anticipate the heat pump technology (conventional or flammable refrigerants). For this reason, there is an effort underway at UL to re-purpose an existing Standard for Refrigerating Units, ANSI/UL 427, to be a general source for refrigeration circuits employed in appliances where the relevant appliance standard does not already include such requirements.

Conclusion

In the 1990s the US market was not ready for the introduction of flammable refrigerants in many HVAC and appliance applications when CFC phase-out began to take effect. However, much experience with equipment using HC refrigerants has been gained around the world in the intervening years. As the drive towards more environmentally friendly refrigerants and greater energy efficiency continues, it’s time to revisit the use of flammable refrigerants in the US. Anticipating that these refrigerants can very quickly attain more widespread use, it is important that the stakeholders of the US safety system take a holistic look at the potential impact of such use, and take the necessary steps to ensure the continued safety track record of HVAC equipment and appliances. UL believes that raising awareness and facilitating dialogue among stakeholders is an important first step in this direction.

References:

[34] ANSI/ASHRAE Standard 34, Designation and Safety Classification of Refrigerants, Scope.

[35] Standard for Safety of Refrigerants, ANSI/UL 2182, Scope.

[36] ANSI/NFPA 58-2011, Liquefied Petroleum Gas Code Clause 1.3.2.

[37] DOT cylinder specifications are provided in 49CFR178, “Specifications for Packaging.”

[38] ANSI/ASHRAE Standard 15-2010, Safety Standard for Refrigeration Systems, Scope.

[39] Refrigerant concentration limit (RCL) is the measure of complete discharge of each independent refrigeration circuit into a volume of space.

[40] ANSI/ASHRAE Standard 15-2010, Safety Standard for Refrigeration Systems, Clause 7.5.3 Higher Flammability Refrigerants, Exception c.

[41] Standard for Safety for Refrigerant-Containing Components and Accessories, Nonelectrical, ANSI/UL 207, Scope.

[42] Standard for Household Refrigerators and Freezers, ANSI/UL 250, Scope.

[43] Tri-national (US, Canada, Mexico) standard based on the eponymous IEC 60335-2-24.

[44] The U.S. EPA is proposing that equipment must have distinguishing colour-coded hoses and piping to indicate use of a flammable refrigerant. They indicate that one unspecified color would be sufficient for both household refrigerator and freezers and retail food refrigeration (stand-alone units). (Federal Register/Vol. 75, No. 89/Monday, May 10, 2010 / Proposed Rules p. 25808).

[45] Standard for Commercial Refrigerators and Freezers, ANSI/UL 471, Scope.

[46] Standard for Safety for Heating and Cooling Equipment, ANSI/UL 1995, Scope.

[47] “In general, ammonia can be used in unlimited quantities in direct systems for industrial occupancies; however it must be used in indirect (secondary) systems for commercial and public occupancies, while its general use in small absorption equipment is unrestricted.” “Ammonia as a Refrigerant,” Position Document Approved by ASHRAE Board of Directors January 17, 2002, Reaffirmed by ASHRAE Board of Directors January 26, 2006, http://www.ashrae.org/docLib/200622793710_347.pdf.

[48] According to the CANENA website (http://www.canena.org/about/about.aspx#canena), “CANENA provides a forum for harmonisation discussions and; upon agreement, the draft harmonised standards are then processed by the respective standards developer in each country, in accordance with that SDO’s procedures.”

[49] ISO 5149, Mechanical refrigerating systems used for cooling and Heating – Safety requirements.

[50] Standard for Hermetic Refrigerant Motor Compressors, ANSI/UL 984, Scope.

[51] Standard for Household and Similar Electrical Appliances, Part 2: Particular Requirements for Motor-Compressors, ANSI/UL 60335-2-34, Scope.

[52] Rockwell Industries Ltd of India claims to be able to produce water coolers using hydrocarbon refrigerant (http://www.rockwell.co.in/aboutus.html).

[53] Patent application filed by Agent BSH Home Appliances, Intellectual Property Department: HOUSEHOLD APPLIANCE CONTAINING A HEAT TRANSFER FLUID, Publication date: 08/26/2010, Patent publication number: 2010-0212178. The patent is described to be “for a household appliance includes a drying chamber, a process air loop and a heat pump. The heat pump includes a heat transfer loop containing a heat transfer fluid, an evaporator heat exchanger, a liquefier heat exchanger, a compressor, and a nozzle. The heat transfer fluid has a critical temperature above 60°C – a nominal heat of vapourisation at boiling point of at least 220 kJ/kg, a GWP index of less than 150 and a lower flammability level of at least 0.1 kg/m3. Preferably, the household appliance is a dryer for drying wet laundry.” (Description obtained from http://www.faqs.org/patents/app/20100212178 where the refrigerant was further described to be R152a).

Copyright © 2006-2025 - CPI Industry. All rights reserved.