In the second installment of the whitepaper on flammable refrigerants, Thomas Blewitt explores the prevalent safety standards and regulations that affect the use of flammable refrigerants in HVAC equipment and appliances.

In the second installment of the whitepaper on flammable refrigerants, Thomas Blewitt explores the prevalent safety standards and regulations that affect the use of flammable refrigerants in HVAC equipment and appliances.

The background

Part I of the Whitepaper, explored the implications of increased and widespread use of flammable refrigerants in HVAC equipment and appliances, and focused on the use of hydrocarbons as refrigerants. It concluded by stating that stakeholder identification was the first step in undertaking a unified and coordinated review of the potential impact of the wider use of flammable refrigerants. It further suggested that gaps in codes and standards for installation and use, including the applicable equipment safety standards, need to be identified and addressed. Education and training for installers, service personnel, storage and retail facilities operators, fire fighters and inspection professionals was also deemed important. Part II endeavours to examine the current state of safety standards in order to address the gaps.

US Federal regulatory environment CFC and HCFC phase out

The phase-out of CFCs began in 1991 – a change that drove equipment manufacturers to expand the use of hydrochlorofluorocarbons (HCFCs) where they could, and to use hydrofluorocarbons (HFCs) in applications as diverse as household refrigerators and automotive air conditioning. Manufacturers began to use hydrocarbons (HCs) as well around this time.

The phase-out of CFCs began in 1991 – a change that drove equipment manufacturers to expand the use of hydrochlorofluorocarbons (HCFCs) where they could, and to use hydrofluorocarbons (HFCs) in applications as diverse as household refrigerators and automotive air conditioning. Manufacturers began to use hydrocarbons (HCs) as well around this time.

As noted earlier, isobutane (R600a) had long ago been used as a refrigerant. With the phase out of CFCs, isobutene was reintroduced as a refrigerant for household refrigerators and freezers in Japan16 and Europe, and found widespread use and acceptance.17 Though ANSI/UL 250, the US safety standard for household refrigerators, anticipated as early as the 1990s the possible use of flammable refrigerants in the US, they were not introduced in US appliances until 2008.

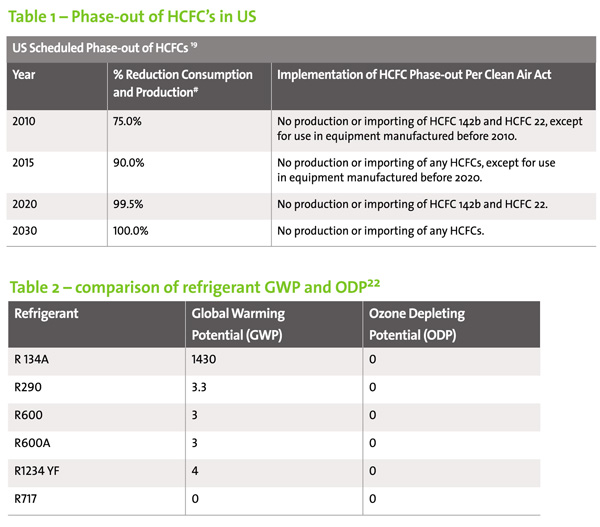

An interim solution, HCFCs are also ozone-depleting substances and were subject to a longer-term phase out than CFCs. In September 2007, the signatories of the Montreal Protocol agreed to a more aggressive phase-out of HCFCs. Table 1 describes the phase-out timetable under the US Clean Air Act. The imminent HCFC phase-out, coupled with recent efforts to improve energy efficiency of certain appliances as well as experience outside of the US market, has substantially renewed interest in the US towards flammable refrigerants, isobutane and propane in particular, along with blends using these substances.

Finally, in September 2008, ice-cream maker Ben and Jerry’s introduced a commercial ice-cream case into the US market, representing the first use of a hydrocarbon refrigerant in a conventional commercial food serving and display application in over 50 years in the country. The self-contained freezer case, made by Unilever, 18 was of a cold wall construction that used propane refrigerant.

Notwithstanding the movement towards HC refrigerants, HFCs currently remain the predominant choice to replace HCFCs. However, under the European Climate Change Programme (ECCP), a 2006 regulation for all F-gases (fluorinated gases) “makes it mandatory to contain via the control of systems via leakage detection systems that are regularly checked, to recover and recycle, to monitor and archive, to label, to train and certificate servicing personnel, to restrict marketing of F-gases for emissive uses, etc.”20 in the European market must also contend with the EU’s directive relating to emissions from air conditioning systems in motor vehicles (2006/40/EC), also known as the MAC Directive.21 The MAC Directive will eliminate the major mobile air conditioning market for the popular HFC 134a, and has led manufacturers to explore a “lower flammability” refrigerant (HFO 1234yf), as well as CO2 and other options.

Somewhat related is the move towards “natural refrigerants.” Looking to avoid altogether the transition to HFCs, which have high global warming potential (GWP), a consortia of equipment manufacturers and retailers have included HC refrigerants in their plans to meet energy regulations.

See Table 2 for some examples of the GWP for flammable refrigerants.

Over time, these various initiatives can be expected to contribute to a reduction in use of HFCs as an alternative to HCFCs, and lead to increased use of HCs.

Energy efficiency

In addition to being affected by the phase-out of ozone-depleting refrigerants, HVAC equipment and appliances employing refrigerants are subject to a variety of regulations in the US. Such equipment must meet the appropriate electrical, mechanical, fire and public health requirements of state and local jurisdictions. Increasingly, such equipment must also meet state and federal energy efficiency goals (e.g. Energy Policy and Conservation Act23) that can be expected to drive the search for new and more efficient technologies, including the types of refrigerant used.

As recently of September 2010, the US Department of Energy proposed standards for residential refrigerators and freezers that are expected to lower energy use by as much as 25%.24 The energy efficiency appeal of flammable refrigerants in refrigeration equipment and air conditioners may also lead to its use in other appliances. For example, a storage tank water heater could potentially be more efficient if a reverse-cycle (heat pump) system with a relatively small flammable refrigerant charge were used instead of a large resistance-heating element to maintain the temperature of the water. A similar technology could be used in a clothes dryer to dehumidify clothing, instead of drying solely by resistance heat or heat of combustion.

US EPA SNAP

It is only logical that the transition towards more environmentally preferable refrigerants and energy savings has renewed interest in HC refrigerants in appliances. And arguably the most significant regulation affecting the use of flammable refrigerants in appliances is the Clean Air Act, administered by the US Environmental Protection Agency (EPA), under its Significant New Alternatives Policy (SNAP).

According to the EPA, the purpose of its SNAP programme is “to allow a safe, smooth transition away from ozone-depleting compounds by identifying substitutes that offer lower overall risks to human health and the environment.”25 SNAP specifically identifies the use of refrigerants used in HVAC equipment and appliances as a focus of the policy, including chillers, cold storage warehouses, retail food refrigeration, vending machines, water coolers, commercial ice machines, household refrigerators and freezers, residential dehumidifiers and residential and light commercial air conditioning and heat pumps.

EPA’s SNAP has authorised HCs (propane, butane and blends) as alternative refrigerants for industrial process refrigeration only. For all other applications, such refrigerants have not yet been authorised as substitutes for refrigerants employed today.26 However, there are exemptions to this restriction for small volume producers of substitutes, and in cases where end-use equipment is being test-marketed or deployed for research and development.27

In response to the increased interest in HC refrigerants, the EPA issued a Notice of Proposed Rulemaking (NPRM) in the US Federal Register in May 2010. The NPRM recommends that “isobutane, propane,

HCR–188C28 and HCR–188C1 be acceptable, subject to use conditions, as substitutes for R–12 and R–22 in household refrigerators, freezers, and combination refrigerator and freezers and commercial refrigeration (retail food refrigerators and freezers – stand-alone units only”).29

The NRPM also references product safety standards ANSI/UL 250 and ANSI/UL 471, indicating that equipment must meet the requirements of these standards to use one of the specified flammable refrigerants. The proposal also specifies that hoses and piping be colour coded to identify the presence of flammable refrigerants in these appliances, and that unique fittings and service ports be provided to avoid accidental connection of inappropriate service equipment while facilitating recovery of refrigerant during service or disposal of the appliances.

Finally, the NPRM proposes that technicians working with equipment using flammable refrigerants be “specifically trained in handling flammable refrigerants service or dispose of refrigerators and freezers containing these refrigerants” to minimise the risk of fire.30

US DOT

The US Department of Transportation (DOT) publishes requirements for “packaging”31 which apply to cylinders that may contain liquefied petroleum gas (LP-Gas). These requirements describe the types and sizes, construction, testing, inspection and markings of these cylinders, often simply referred to as “DOT cylinders.” The requirements are well established for the transport of LP-Gas cylinders for combustion equipment and, together with regulations from the US. Occupational Safety and Health Administration (OSHA) associated with workplace handling of LP-Gas, thoroughly cover transportation of flammable gas in cylinders.

HVAC equipment and appliances containing flammable refrigerant could be identified as hazardous material cargo due to the presence of flammable gas. 49 CFR Part 177.834 (Packages secured in a motor vehicle) states: “Any package containing any hazardous material, not permanently attached to a motor vehicle, must be secured against shifting, including relative motion between packages, within the vehicle on which it is being transported, under conditions normally incident to transportation. Packages having valves or other fittings must be loaded in a manner to minimise the likelihood of damage during transportation.”

Fortunately, the Federal Motor Carrier Safety Administration (an agency of the DOT) reports that “crashes involving large trucks-those with a gross vehicle weight rating of more than 10,000

Pounds – carrying hazardous materials (hazmat) are relatively rare.”32

US OSHA

OSHA publishes regulations intended to protect the safety or health of those employees working in federally-regulated workplaces. National consensus standards are frequently referenced for this purpose and, in accordance with 29 CFR 1910.7(c), ANSI/UL standards for refrigerators and freezers, heating and air conditioning equipment, associated components and appliances fulfill the requirements. Such products, once listed by a nationally recognised testing laboratory (NRTL) using the accepted standards, may be used in the workplace.

OSHA regulations addressing storage and handling of LP-Gases are documented in 29 CFR 1910.110. While these regulations do not anticipate LP-Gas refrigerants, they do cite compliance with DOT container requirements33 and location of containers in buildings.

Of particular relevance for the servicing of HVAC equipment and appliances in-place is 1910.110 c) 5, which states that “when operational requirements make portable use of containers necessary and their location outside of buildings or structure is impracticable, containers and equipment are permitted to be used inside of buildings or structures….” There are also caveats to this allowance and they are comparable to the requirements of NFPA 58 (Liquefied Petroleum Gas Code).

Installation requirements and equipment safety standards environment

Fulfilling government regulations is only part of the compliance landscape for HVAC equipment and appliance manufacturers. Equipment must also comply with safety standards in order to be installed in a workplace or (depending upon the local jurisdiction) in other occupancies. Retailers, insurers and other parties may also require evidence of compliance with safety standards.

In the US, UL is the principal standards developer addressing electrical appliance and HVAC equipment safety. UL standards are part of an overall safety system of coordinated standards and codes to facilitate safe installation and use of equipment. They complement the electrical installation requirements of the National Fire Protection Association (NFPA), notably the National Electrical Code® (NFPA 70), and mechanical refrigeration requirements of the ASHRAE, Standards 15 and 34.

Installation codes for HVAC and refrigeration equipment are published by International Codes Council (ICC International Mechanical Code, Chapter 11) and the International Association of Plumbing and Mechanical Officials (IAPMO Uniform Mechanical Code, Chapter 11). Both mechanical codes reference ASHRAE 15 and 34, with additional requirements. (to be continued …).

Vapour compression refrigeration and air conditioning end uses

(Table content extracted from EPA web content: http://www.epa.gov/ozone/snap/refrigerants/index.html) |

Disposal“Refrigeration and air conditioning equipment that is typically dismantled on-site before disposal (eg, retail food refrigeration, central residential air conditioning, chillers, and industrial process refrigeration) has to have the refrigerant recovered in accordance with EPA’s requirements for servicing prior to their disposal. However, equipment that typically enters the waste stream with the charge intact (eg, motor vehicle air conditioners, household refrigerators and freezers, and room air conditioners) are subject to special safe disposal requirements. Under these requirements, the final person in the disposal chain (eg, a scrap metal recycler or landfill owner) is responsible for ensuring that refrigerant is recovered from equipment before the final disposal of the equipment. If the final person in the disposal chain accepts appliances that no longer hold a refrigerant charge, that person is responsible for maintaining a signed statement from whom the appliance/s is being accepted. The signed statement must include the name and address of the person who recovered the refrigerant, and the date that the refrigerant was recovered, or a copy of a contract stating that the refrigerant will be removed prior to delivery.” (Content taken from EPA web site fact sheet: http://www.epa.gov/ozone/title6/608/608fact.html) |

In addition, requirements for the storage, use and handling of refrigerants are published by ICC (International Fire Code, Section 606) and the NFPA (NFPA 1, Chapter 53). These model fire codes impose safety requirements for occupancy based on the volume and safety group of the refrigerant. As with any of the model codes (electrical, mechanical, fire, etc), local jurisdictions can implement variations and additional requirements for equipment, and may elect to do so for HVAC equipment and appliances employing flammable refrigerants, especially in densely populated areas. The remainder of this paper summarises the current status of many of the standards and codes relevant to flammable refrigerants, as follows:

The first three standards listed above are applicable to refrigerants, while the remainder are applicable to equipment and components. These and other standards also address ammonia, but that particular refrigerant is outside the scope of this paper. |

REFERENCES

[16] “In 2002, Japan, a major producer of domestic refrigerators/freezers, introduced its first hydrocarbon (HC) refrigerators onto the market. HC refrigerants, especially R-600a, have since dominated the Japanese domestic refrigeration market and are continuing to grow in market share.” Quoted from “Transitioning to Low GWP Alternatives in Domestic Refrigeration,” US Environmental Protection Agency, EPA-430-F-10-042, October 2010 (http://www.epa.gov/ozone/ downloads/EPA_HFC_DomRef.pdf).

[17] “Practical Application of Refrigerant R600a Isobutane in Domestic Refrigerator Systems,” Danfoss, November 2000.

[18] Unilever is the world’s largest producer of ice cream (Breyers and Ben and Jerry’s brands in US). Since 2004, the company has been replacing commercial freezers that display their products with units using hydrocarbon (HC) refrigerants, around 430,000 units to date (11/2010) according to their website (unilever.com).

[19] Simplification of a table appearing on EPA web site: US EPA Ozone Layer Protection – Regulatory Programmes, “Comparison of the Montreal Protocol and United States Phaseout Schedules,” http://www.epa. gov/Ozone/title6/phaseout/hcfc.html. Referenced cap is average of a) 1989 HCFC production + 2.8% of 1989 CFC production and b) 1989 HCFC consumption + 2.8% of 1989 CFC consumption.

[20] “Natural Refrigerants Sustainable Ozone- and Climate-Friendly Alternatives to HCFCs,” Proklima International, published by Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH, July 2008, p 31.

[21] The Directive covers the use of refrigerants with global warming potential (GWP) over 150 in Mobile Air Conditioning for passenger cars only. The intent is to restrict direct emissions from such systems. The Directive will be implemented beginning in 2011 with a target of full implementation by 2017.

[22] “Transitioning to Low GWP Alternatives in Commercial Refrigeration” EPA-430-F-10-043 October 2010 (http://www.epa.gov/ozone/downloads/EPA_HFC_ComRef.pdf) and “Transitioning to Low GWP Alternatives in MVACs,” EPA-430-F-10-041, October 2010 (http://www.epa.gov/ozone/downloads/EPA_HFC_MVAC.pdf).

[23] “Minimum standards of energy efficiency for many major appliances were established by the US Congress in Part B of Title III of the Energy Policy and Conservation Act (EPCA), … the National Energy Conservation Policy Act, … the National Appliance Energy Conservation Act, … the National Appliance Energy Conservation Amendments of 1988, … and by the Energy Policy Act of 1992, … and by the Energy Policy of 2005….” US DOE, Building Technologies Program, “Appliances & Commercial Equipment Standards, Laws and Regulations,” http://www1.eere.energy.gov/buildings/appliance_standards/laws_regs.html.

[24] US DOE Press Release: “DOE Proposes Higher Efficiency Standards for Refrigerators,” September 28, 2010, http://www. energy.gov/news/9582.htm.

[25] US EPA Ozone Layer Protection – Alternatives / SNAP, “Significant New Alternatives Policy (SNAP) Program,” http://www.epa.gov/ozone/snap/index.html.

[26] US EPA Air and Radiation Stratospheric Protection Division 6205J, “Substitute Refrigerants Under SNAP as of June 16, 2010,” http://www.epa.gov/ozone/ snap/refrigerants/reflist.pdf.

[27] US EPA Guidance document for the Significant New Alternatives Policy (SNAP), Program Information Notice EPA-1265-07 June 30, 2011 (sic), p. 16.

[28] The “refrigerant is a blend of propane, isobutane, ethane, and pentane gases, with variations that include hexane, methane, and heptane.” Appliance Design, “Cooling Technologies: Alternative Refrigerants Attract Attention,” Larry Adams, March 31, 2009 (http:// www.appliancedesign.com/Articles/Article_Rotation/BNP_GUID_9-5- 2006_A_10000000000000558309).

[29] Federal Register/Vol. 75, No. 89/Monday, May 10, 2010 /Proposed Rules p. 25799

[30] Ibid, p 25809

[31] US Code of Federal Regulations, 49CFR178 “Specifications for Packagings.”

[32] US DOT Federal Motor Carrier Safety Administration Office of Information Management, “Crashes Involving Trucks Carrying Hazardous Materials,” by Ralph Craft, PhD, Publication #: FMCSA-RI-04-024, May 2004 http://www.fmcsa.dot.gov/facts-research/research-technology/ analysis/fmcsa-ri-04-024.htm.

[33] Other containers may also be employed where appropriate (eg those complying with the Rules for Construction of Unfired Pressure Vessels, Section VIII, Division 1, ASME Boiler and Pressure Vessel Code).

Thomas Blewitt is Director of Primary Designated Engineers, Underwriters Laboratories and can be contacted at: Thomas.V.Blewitt@ul.com

Copyright © 2006-2025 - CPI Industry. All rights reserved.