Why this technology for condenser water treatment is being regarded as the future in the context of chilled water systems

Dan Mizesko is the Managing Partner at Al Shirawi US Chiller Services

Non-chemical pulsed power water treatment technology is worth a look-in, for it completely eliminates the need for any and all chemicals typically used in a condenser/cooling tower system.

The primary goals of advanced water treatment in HVAC systems are to prevent mineral scale formation, control biological activity and inhibit corrosion. These problems traditionally have been addressed by means of chemical additives. Difficult to administer, monitor and control, chemical additives are ultimately discharged to the environment, where they can contaminate surface and ground waters. In addition, they remain as concentrate in water treatment plant residuals, and are directly aspirated into the atmosphere and inhaled by people exposed to the mist created by cooling tower drift.

The pulsed-power technology changes the form of precipitated solids from “hard lime scale” to a harmless powder

To resolve these and many other problems associated with traditional chemical water treatment, I would encourage you to look at pulsed-power, non-chemical water treatment technology. In addition to eliminating all chemical usage, the technology will allow you to increase the cycles of concentration in the cooling tower, thus substantially reducing make-up and blow down water requirements and associated water costs. It will reduce the carbon emissions associated with water production, transmission and distribution and allow the end-user to earn points toward LEED Green Building Council certification. And broadly speaking, it will demonstrate to the region that you are a leader in environmental stewardship and that you comply with government mandates that all UAE buildings and industries move to a “Greener” footprint.

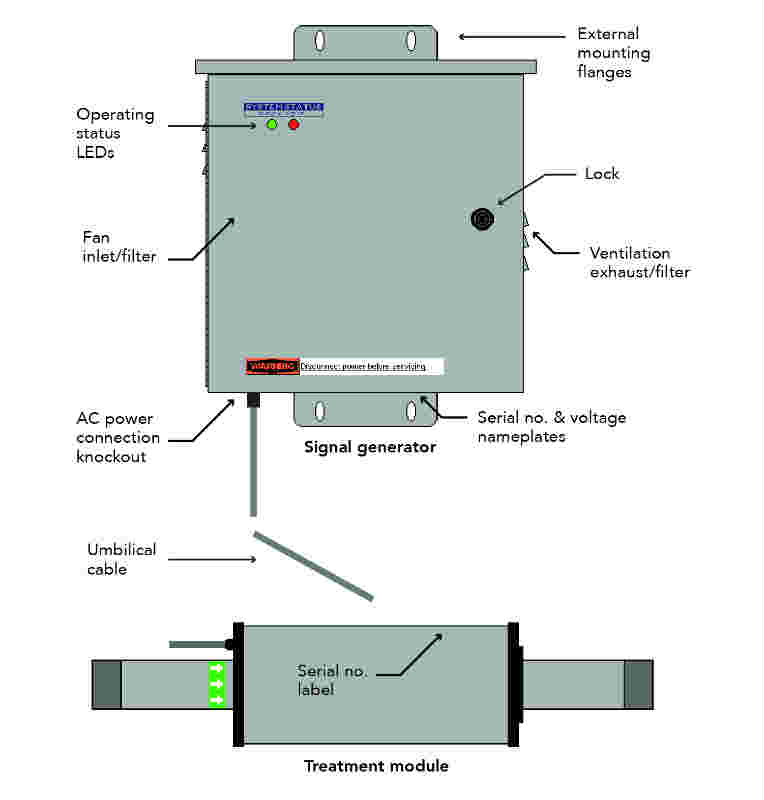

Figure 1

The pulsed-power technology is a proven, reliable and chemical-free way to treat the process water of the cooling towers, through scientific principles. The technology offers major advantages for standalone, central and District Cooling chilled water plants, facilities and buildings.

Operational performance

The pulsed-power technology improves the operational performance of the water-based systems to which it is applied, be they chillers, towers or pumps. It makes these systems more efficient and longer lasting by eliminating such performance inhibitors as scale, corrosion, bacteria, biofilm, encrustation and fouling. In other words, it will decrease the lifecycle costs associated with towers, chillers and pumps.

Environmental stewardship

Since it is a chemical-free water treatment technology, it prevents exposure to and migration of hazardous chemicals. The best way to prevent exposure to hazardous materials is to not bring them into a facility. The technology typically resolves more than 10 OSHA and EPA concerns associated with chemical treatment.

Principles of operation

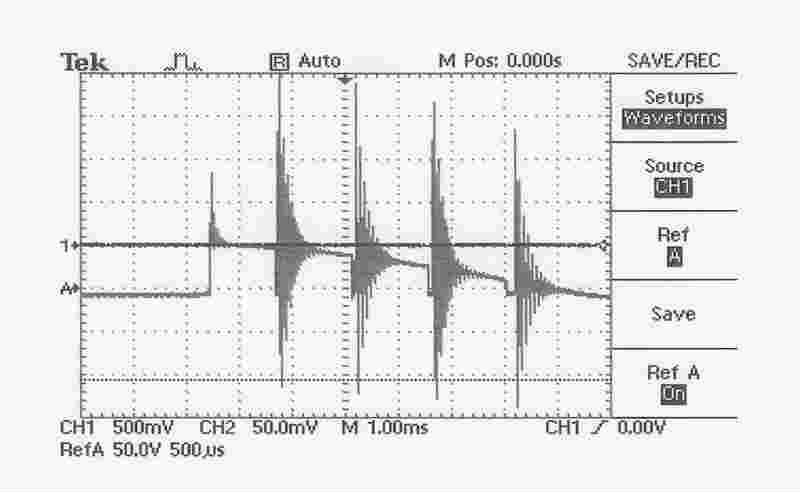

The technology imparts pulsed, high-frequency electric fields into flowing water. The characteristic waveform is as shown in Figure 2.

Figure 2

Scale prevention

In the absence of the pulsed-power technology, the pressure to form solids is relieved by the formation of scale on equipment surfaces

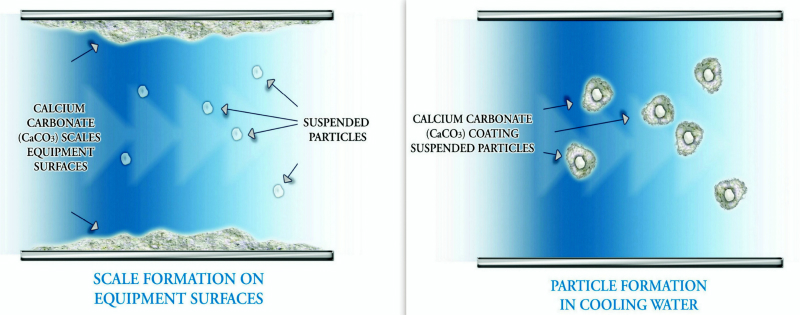

When evaporation occurs in a cooling tower, the water exits as water vapour and leaves the dissolved minerals behind, causing increased concentration. Upon sufficient concentration, the dissolved minerals, such as calcium carbonate (i.e., limestone) become solid in a process known as precipitation. The pulsed-power technology changes the form of precipitated solids from “hard lime scale” to a harmless powder.

The technology accomplishes this change by “activating” naturally occurring suspended particles in the water. The tiny particles exist in large quantities in all city water or well water that is used as cooling tower or boiler make-up water. When exposed to the pulsed-power technology, the suspended particles act as seeds for precipitation of dissolved minerals. The technology activates the particles by removing the static electric charge on their surface.

Figure 3

A powder of calcium carbonate (limestone) grows by coating or adhering to the suspended seed particles. The powder formation relieves the ever-growing pressure to form solids that occur from the increasing mineral concentration, before scale has a chance to form on equipment surfaces. In the absence of the pulsed-power technology, the pressure to form solids is relieved by the formation of scale on equipment surfaces. The process is much like seeding a cloud to produce rain when weather conditions are building up water concentration in the atmosphere.

In removing the surface charge on suspended particles, the technology makes those particles the preferred sites for precipitation to occur. Thus, the minerals coat or adhere to the suspended particles rather than equipment surfaces. These coated particles or powder can easily be removed from a cooling tower basin by manual means, filtration, or centrifugal separation. The quantity of powder is typically about 15% of normal blown-in dirt in a cooling tower. In a boiler, the powder exits through normal bottom blowdown.

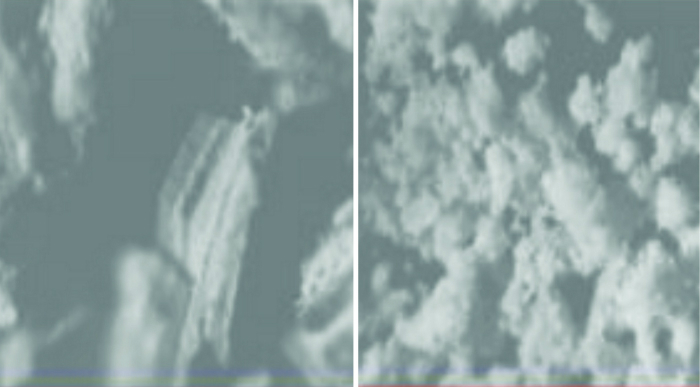

Figure 4

Photo-micrographs of the two mineral formations are shown in the following magnifications (Figure 4).

Next month, I shall be sharing with you how the pulsed-power technology ensures bacterial control and corrosion control and inhibits algal growth. Till then, goodbye!

Dan Mizesko is the Managing Partner of Al Shirawi US Chiller Services. He can be contacted at dan@uschillerservices.com

[div class=”row”]

[div class=”col-md-10 col-md-offset-1 content-sidebox”]

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

[end-div]

[end-div]

Copyright © 2006-2025 - CPI Industry. All rights reserved.