When it comes to non-chemical condenser water treatment, how does pulsed power technology stack up against other non-chemical water treatment options?

The primary goals of advanced water treatment in HVAC systems are to prevent mineral scale formation, control biological activity and inhibit corrosion. These problems traditionally have been addressed by means of chemical additives. Difficult to administer, monitor and control, chemical additives are ultimately discharged to the environment, where they can contaminate surface and ground waters, concentrate in water treatment plant residuals and be directly aspirated into the atmosphere and inhaled by people exposed to the mist created by cooling tower drift.

To resolve these and many other problems associated with traditional chemical water treatment, non-chemical treatment technologies have emerged. I can say without hesitation the only non-chemical treatment that outperforms chemical water treatment is pulse power.

One of the strengths of pulse power is its comprehensive ability to deal with all water treatment issues. Many non-chemical products deal with only one issue, therefore requiring other methods for the remaining issues.

Consider these products in two broad categories:

Single technology products, and 2) Hybrid technology products. The hybrid products recognise the disadvantage of treating only one issue and, therefore, make various combinations. The hybrids combine so many technologies to treat the condenser water loop, so I will discuss the single technologies generically. A special case of hybrid is the non-chemical/chemical hybrid, which supplements a single technology non-chemical product with the use of traditional chemical treatment to deal with the issues not addressed by the non-chemical product. Obviously, the chemical portion of this approach does not provide the full benefits of 100% non chemical water treatment, including environmental problems, performance problems and continuing cost.

The reader is familiar with these arguments, and they will not be repeated here, as I covered them in a past issue. As stated, the three water treatment issues that must be addressed in a cooling system are preventing mineral scale, controlling biological growth and achieving corrosion resistance. Pulse power technology handles all three, but there are a couple of special cases where chemicals could be beneficially used with pulse power technology, and this is discussed at the end of this article.

Within the single technology products, we will further classify into the following categories:

ELECTRIC DEVICES

Electro-magnets and permanent magnets:

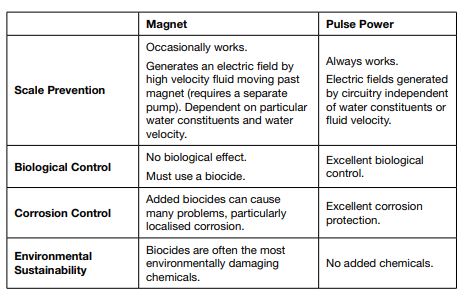

Although permanent magnets are not electric, they work on the same principal as direct current electromagnets. They create a magnetic field in the water, which they hope will create an electric field through very high velocity water flow within the magnetic field. They have very poor reliability of performance, owing to their reliance on turbulence to create the electric field. Even at high velocity, there is little assurance that the required electric field will be formed due to turbulence. There is no credible evidence that magnets have any biological effect.

Magnets in cooling tower applications:

Under some conditions, magnets can prevent mineral scaling. When they work, magnets will generate a few seed crystals. It is the electric field that is generated that does the work, and magnets can generate a weak electric field by fluid passing through the fixed magnetic field. This is called the Lorentz Effect, with the strength of the electric field dependent on the velocity and make-up of the water as well as the positions and strength of the magnet. The electric fields are weaker than those generated by pulse power and dependent on particular conditions of the installation. Magnets have no direct effect on biological growth and are always paired with some biocide.

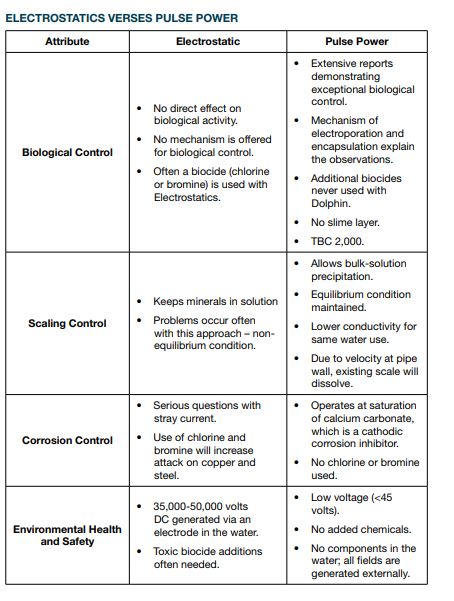

Electrostatic devices:

These products skip the uncertainty of creating the required electric field with a magnetic field. They create the electric field by the direct means of creating an electric potential difference between two conductive points inside the water flow. The electrostatic devices have only a marginal impact on preventing scale. There is no credible evidence that electrostatic devices have any biological effect. An electric potential difference created this way will generate electric force lines around the anode and cathode points of the system; these lines can impinge on metal surfaces near their installation location and create potentially severe localised corrosion. The water’s conductivity is enough to create a corrosion cell that is analogous to battery with its electrode plates corroding (the battery’s plates represent the metal structures in the cooling system).

Precipitation Induction Devices (PID):

The Pulse Pure Technology is within this family but different. Pulse Pure incorporates two crucial features: 1) High-frequency pulsing, and 2) Proprietary interaction between electric fields. Absent these two features, the alternating current PID has only a marginal impact on preventing scale. There is no credible evidence that PIDs have any biological effect.

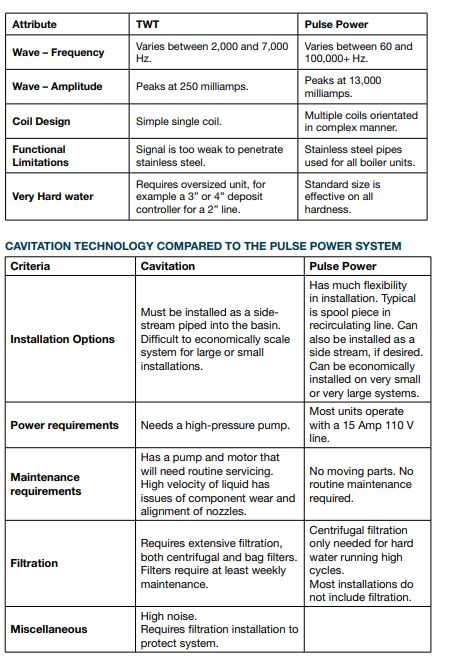

Triangular Wave (PID) versus Pulse Power

Triangular Wave Technology (TWT) devices do not have a biological effect and must be combined with copper-silver electrodes (chemical additions) for biological control. TWT probably does have some anti-scaling effect, but the Dolphin System is superior to TWT in that area, too.

CAVITATION DEVICES

Apparently, cavitation (the implosion of micro-bubbles in the water) has a similar effect to that of an electric field at removing the surface charge on suspended particles. As such, it should be effective at preventing mineral scale. Cavitation is an expensive effect to produce, and it has some problematic side-effects.

CHEMICAL ADDITIONS IN NON-TRADITIONAL FORMS

Ozone: Ozone is a very effective oxidising biocide that has had 40 years to establish a market in cooling towers with little success. It is distinguished from other biocides in that it is added in gaseous form rather than as a liquid, and it is more environmentally benign than other biocides. There is no credible evidence that ozone has any scale-prevention effect. The side effects, corrosion problems, complexity, safety and cost of ozone have blocked ozone’s market acceptance in cooling towers.

Ozone for cooling towers

Ozone is a chemical that is usually produced by passing an electric current through dry gas containing oxygen. The chemical formula for ozone is O3, compared to oxygen gas, which is O2 . Ozone in the upper atmosphere blocks UV light and is environmentally beneficial; however, ozone at ground level is the primary contributor to smog and air pollution. Ozone is a very strong and indiscriminate oxidiser and, when it breaks down, forms oxygen gas. Ozone reacts with other minerals to form disinfection by-products, which have unknown environmental effects.

Copper silver electrodes (Cu/Ag): Electrode devices are just a means of adding chemical biocides in a solid form. Electricity dissolves the electrodes slowly, thus adding the chemicals over time. These biocides are not particularly effective, although they are more environmentally benign than those used by chemical water treaters. There is no credible evidence that Cu/Ag has any scale-prevention effect.

Copper/silver electrodes for cooling tower applications

OTHERS

1. Alternative chemicals: Chlorine dioxide is a biocide with a limited environmental impact; however, it is highly explosive. It’s not a serious alternative to chemical treatment, but just a slight variation of chemical choice. In addition, iodine additives – not particularly effective biocides – do not represent a non-chemical choice.

2. Good technologies misapplied: Ultraviolet light is an effective biological killing agent, but the difficulties of applying it to a cooling tower application make it an unviable alternative. Additional issues include 1) Biological control only, 2) No effect on biofilm, 3) Cost of electricity and bulbs.

3. Solids separators and filters: These devices make for a cleaner tower with Pulse Pure treatment, chemical treatment or non-chemical hybrid treatment. While I encourage their use in a system, they are hardly an integral part of a non-chemical hybrid in addressing the three primary issues of water treatment.

4. New technology: A large chemical water treatment company has just introduced a chemical/non-chemical hybrid that uses an ultrasonic pressure wave to prevent scale and control biological life. I can find little support for this theories or evidence of success, though.

Pulse Pure with chemicals

Pulse Pure does do it all: Anti-scaling, biological control and corrosion resistance. However, there are times when some chemicals can help; so, for the sake of completeness they are mentioned here…

Algaecide: Sometimes, persistent algae blooms can occur in a tower due to blown-in nutrients and sunlight. It is not indicative of a biologically active tower, but if it were seriously undesirable, algaecide would be an acceptable addition. However, note that algaecide is not particularly effective with heavy blown-in sediment, or within certain cooling tower models that are very open to sunshine.

Corrosion inhibitor: A tower that will be left wet and unused for months will need corrosion inhibitor to protect its uncoated steel or iron; at this juncture, I must add that there are no problems with galvanised, stainless, copper-base or others. Calcium-bearing swimming pool chemicals may be a particularly benign form of corrosion inhibitor for this purpose. However, note that any corrosion inhibitor that is uncirculated for months will have little protective effect.

pH adjuster: A new galvanised tower must have its zinc conditioned by having water of less than pH 8.3 for six weeks. If local make-up water is above pH 8.3 – a very rare occurrence – a pH adjuster must be used for six weeks.

PULSE POWER

Pulse power, in addition to eliminating all chemical usage, will allow you to increase the cooling tower Cycles of Concentration, thus substantially reducing make up and blow down water requirements and associated water cost. It will reduce the carbon emissions associated with water production and distribution and will allow the end user to earn points towards LEED Green Building Council certification. In the past, I have explained pulse power in detail, including its features and benefits. The following is an explanation of other non-chemical water treatment technologies and a comparison. The pulsed power system is a proven, reliable and chemical-free way to treat the process water of cooling towers.

Through scientific principles, the system offers major advantages for standalone, central and district cooling chilled water plants, facilities and buildings. Chilled water systems that have a cooling tower can benefit from pulsed power technology Exceptional system performance The pulsed power system improves the operational performance of the water[1]based system (chillers, towers, pumps) to which it is applied. The pulsed power technology makes these systems more efficient and longer lasting by eliminating performance inhibitors such as scale, corrosion, bacteria, biofilm, encrustation and fouling. Indeed, it will actually decrease the life cycle cost of towers, chillers and pumps.

Since it is chemical-free water treatment, the pulsed power system prevents exposure to and migration of hazardous chemicals. The best way to prevent exposure to hazardous materials is not to bring them into a facility. The technology resolves more than 10 OSHA and EPA concerns associated with chemical treatment.

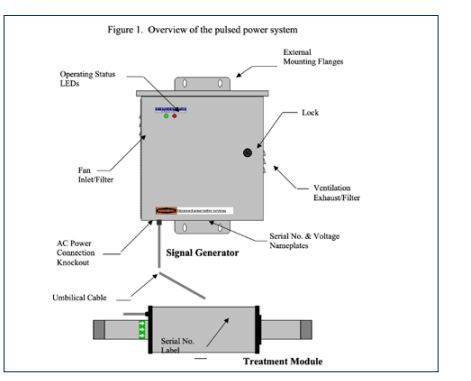

The pulsed power system creates significant energy savings, because it eliminates scale and biofilm. The pulsed power equipment has been designed for superior performance, ease of installation, minimal maintenance, longevity and low-cost operation. The system consists of two main components:

PRINCIPLES OF OPERATION

The system imparts pulsed, high-frequency electric fields into flowing water.

SCALE PREVENTION

When evaporation occurs in a cooling tower, the water exits as water vapour and leaves the dissolved minerals behind, causing increased concentration. Upon sufficient concentration, the dissolved minerals, such as calcium carbonate (i.e., limestone) become solid, owing to precipitation. The system changes the form of precipitated solids from “hard lime scale” to a harmless powder. The pulse power system accomplishes this change by “activating” naturally occurring, small-suspended particles in the water.

These tiny suspended particles exist in large quantities in all city water or well water that is used as cooling tower or boiler make-up water. Under system treatment, the suspended particles act as seeds for precipitation of dissolved minerals. The system activates the suspended particles by removing the static electric charge on their surface. A powder of calcium carbonate (limestone) grows by coating or adhering to the suspended seed particles. The powder formation relieves the ever-growing pressure to form solids that occur from the increasing mineral concentration, before scale has a chance to form on equipment surfaces. Without pulse power treatment, the pressure to form solids is relieved by the formation of scale on equipment surfaces. The process is much like seeding a cloud to produce rain when weather conditions are building up water concentration in the atmosphere.

BACTERIAL CONTROL

Pulse power has two methods of controlling microbial populations in cooling systems: encapsulation and electroporation.

The limestone-type powder, previously described, incorporates most of the free-floating (i.e., planktonic) bacteria. Without Pulsed Power treatment, the bacteria are repelled by the suspended particles due to the fact that nearly all tiny particles have similar negative static electric charges on their surfaces. Once the system powder is growing, the repulsion to bacteria is eliminated; therefore, the bacteria are attracted to powder by other natural forces (i.e., van der Waals forces) and become entrapped in the powder particle. The powder, in effect, sweeps the water clean of planktonic bacteria and renders them incapable of reproducing.

The high-frequency, pulsing action of the system’s electric fields damages the membranes of planktonic bacteria by creating small “pores” in their outer membrane. The condition weakens the bacteria and inhibits their capability to reproduce. The combined effect of these two separate methods, encapsulation and electroporation, results in exceptionally low total bacterial counts (TBC) in cooling tower water.

Microbial life is encapsulated into the forming powder, preventing it from reproducing. Microbes have a 24- 48-hour life span. Any microbes not captured in the forming powder are “zapped” by the secondary pulse, forcing them to spend their life span repairing cell wall damage rather than reproducing. Biofilm or slime Normally, bacteria form a biofilm or slime layer on equipment surfaces.

A biofilm consists of a slimy bacterial secretion that forms a protective canopy to protect the bacteria beneath it from chemical biocides. It is very slimy to the touch, four times more insulating to heat transfer than mineral scale and is the primary cause of microbial influenced corrosion. The bacteria that live in a biofilm adhering to an equipment surface are called sessile bacteria and represent 99% of the total bacteria in a system.

The system eliminates the slime layer through the process of nutrient limitation. All the living organisms in a cooling tower depend on each other for their food supply. Thus, when the nutrients from the planktonic bacteria are diluted by encapsulation and electroporation, the biofilm cannot be sustained and will not be created; or, it will disintegrate it if one already exists prior to system installation or operation.

CORROSION CONTROL

The most serious corrosion concerns in a cooling tower or boiler come from chemical additives. Removing chemicals, avoiding the use of softened water and using the chemical-free pulse power system eliminates those concerns. Other serious concerns come from localised corrosive attack caused by biofilm or mineral scale. Under pulse power system treatment, these conditions are absent, and therefore these types of corrosion are eliminated…

Of all the forms of corrosion, localised corrosion is of most concern, because it can cause rapid deterioration and leaks in a system. Localised corrosion can only be detected visually (except in the case of eddy current testing of chiller tubes to detect the localised attack caused by chemicals or biofilm). Localised corrosion can be eliminated virtually by pulse power treatment. Types of localised corrosion that could be present in cooling towers or boilers include: Microbial-influenced corrosion, pitting and under-deposit corrosion of several varieties.

Uniform corrosion is characterised by the slow dissolving of entire metal surfaces. It is of minimal concern, because it rarely limits equipment life due to the corrosion resistance of the metals used for equipment construction. Corrosion coupons, which use the weight loss of a metal sample to measure uniform corrosion rates, are a reliable method of corrosion monitoring. Galvanised sheet steel and stainless-steel show no uniform corrosion in pulse power-treated systems. Copper and plain carbon steel experience minimal uniform corrosion within industry accepted norms in pulse power-treated systems.

In a cooling tower, the method the system employs to ensure low uniform corrosion rates is to take advantage of the natural corrosion-inhibiting powers of calcium carbonate. The system manages cooling tower water so that calcium carbonate powder is always forming.

Calcium carbonate in that state, called saturation, acts as a powerful cathodic corrosion inhibitor. As such, it greatly slows the corrosion process by blocking the reception of electrons that are thrown off by the corrosion process. With no place for the electrons to go, the corrosion process is physically and very effectively controlled.

ALGAE

Algae are plants which, like all plants, require sunlight and nutrients to grow. In cooling towers, algae are aesthetically undesirable and may promote other microbial growth. However, unless the algae interfere with the thermal performance of the tower by blocking fill or plugging nozzles, it is, in itself, relatively benign. A biologically active system is one with an active slime layer and high planktonic bacteria count. Such a system is at risk of poor thermal performance, microbial-influenced corrosion and pathogens.

Algal growth, combined with high total bacteria count, can be a warning sign of a biologically active system. Algal growth, combined with low Total Bacteria Count (TBC), is NOT a warning sign for a biologically active system. Consistently low total bacteria counts are a sign of a biologically INACTIVE system, regardless of the presence or absence of algae.

Algal growth may be particularly noticeable during the spring and summer. As previously noted, algae require sunlight to grow; therefore, open cooling systems and systems that receive direct sunlight are more prone to algal growth. Blown-in dirt and nutrients also promote algal growth. The system provides excellent microbial control and good algae control under most situations.

However, a combination of one or more of the following factors may result in some opportunistic and relatively benign algal growth:

If the amount of algae is undesirable, the following actions can be performed to minimise a persistent algal bloom:

MONITORING

The following three measurements are key to maintaining a well-run cooling tower:

These three parameters should be measured and recorded once per month on large cooling systems of 600 tons of cooling or greater, and once per quarter on smaller systems. Occasionally, Total Dissolved Solids (TDS) is used as an alternative measurement of conductivity. Under pulse power treatment, TDS is less accurate and should not be used.

The pH in a cooling tower under pulse power treatment will naturally rise and level off between 8.0 and 9.0, depending on local conditions. Conductivity in cooling tower water should approximately match the setting on your conductivity controller that operates the system blowdown.

In closing, I would encourage you to be a leader and visionary, as pulse power is, in fact, proven and superior to chemical water treatment and any other form on non-chemical water treatment.

Copyright © 2006-2025 - CPI Industry. All rights reserved.