Here’s the lowdown on the manufacturing process of water expanded polyurethane panels for pre-insulated aluminium ducts. By Eng. Antonio Temporin and Eng. Andrea van Schalkwyk.

Here’s the lowdown on the manufacturing process of water expanded polyurethane panels for pre-insulated aluminium ducts. By Eng. Antonio Temporin and Eng. Andrea van Schalkwyk.

THE COMPLETE MANUFACTURING PROCESS

The manufacturing of Polyurethane pre-insulated aluminium panels is a delicate and extremely complex process which requires the skill and knowledge of both mechanical and chemical properties alike.

From a mechanical and production plant point of view, panels are produced via a continuous process of the distribution of liquid components to a spraying head which floats between two sheets of aluminium foil.

The liquid components are pumped directly to the mixing head from tanks in the temperature-controlled preparation room, where the Polyol is mixed with further additives which differ according to the characteristics of the specific panel that is required to be produced.

The Isocyanate on the other hand, is pumped directly to the production line from the tank.

Polymerisation and foaming take place in a rolling mill type process formed by two overlapping conveyor belts.

The required panel thickness can range from 12 mm to 50 mm and is determined by the distance set between the two belts. The rolling mill travels in a continuous loop into a curing tunnel which has been pre-heated.

The polymerised foam panel leaves the rolling mill and is cut to size using an automatic cutting system unit.

All process waste materials are removed, collected into silos, compacted and then sent to collection bins for subsequent external disposal.

The manufactured panels are then stacked in bundles and further packaged in heat-shrink protective polyethylene to minimise material damage during the freight handling process.

The panel packages are then sent to the warehouse ready for use and/or distribution.

THE CHEMICAL REACTION PROCESS

From a chemical point of view, traditional polyurethane foaming technology exploits the heat of the exothermic reaction between the Polyol and Isocyanate materials to evaporate a liquid with a low boiling point (CFC, HCFC, HFC, HC) previously added to the mixture. Most of these gases remain trapped inside the cellular structure of the polyurethane polymer being formed. However, part of these gasses are released into the environment over a period of time. With the passage of time, the composition of the gas contained in the cells may vary due to the natural tendency to reach equilibrium with the outdoor surroundings. This process is significantly influenced by the type of external facing given to the foam and its density, operating temperature, formulation and the type of gas used during the manufacturing process itself.

When reaching the atmosphere, chlorinated gases like CFC and HCFC are struck by ultraviolet radiation that leads to the release of radical chlorine through photo dissociation. The radical chlorine then reacts with the ozone and causes its continual destruction.

Using Hydrotec water technology on the other hand, foaming is obtained only by the gas generated through the chemical reaction between the Isocyanate, water and the consequent further reaction during the Polyol and Isocyanate process, which then results in the polyurethane chain being identical to that of CFC, HCFC, HFC or HC respectively.

Polyurethane pre-insulated aluminium panels manufactured using Hydrotec water technology result in the elimination of the greenhouse effect (GWP=0) and the impact on the Ozone layer present in the atmosphere (ODP=0).

The environmental compatibility of these panels has been achieved through the use of water in the expansion process of the polyurethane foam in substitution to the greenhouse effect fluorinated gasses (CFC, HCFC, HFC) and of the hydrocarbons (HC).

The Hydrotec water technology used in the expansion of the Rigid Polyurethane PUR complies with all European Standards and anticipates future provisions which, from a restriction point of view, will see a gradual phase out and subsequent ban on all fluorinated gasses in currently ‘non restricted’ regions of the world.

ACHIEVED INSULATION ATTRIBUTES

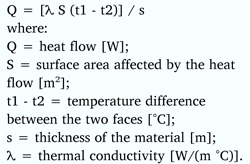

The Rigid Polyurethane PUR panels produced using the Hydrotec water expansion technology also have an extremely high “insulation value”. A material’s “insulation value” is the characteristic used to reduce the transmission of heat between two environments with different temperatures. The quantity of heat Q transmitted between the opposing parallel faces of a flat layer of homogenous material in a stable environment can be expressed using the equation detailed below:

The thermal conductivity, can therefore numerically be quantified as the heat flow that travels through a unitary surface with a unitary thickness and when the difference in temperature between those two faces of the considered layer of material also remains unitary.

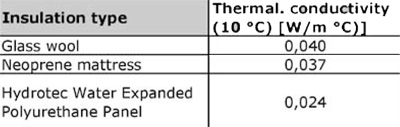

Expanded polyurethane panels which are manufactured using the Hydrotec water expansion technology are currently one of the best heat insulation materials available on the market. As can be seen below, where various insulating materials used in air ducting applications have been compared;

The authors are respectively the Chief Scientist and Technical / Commercial Manager of P3 Srl – P3ductal Preinsulated Panels System, Padua Italy. They may be contacted at info@p3italy.it.

Copyright © 2006-2025 - CPI Industry. All rights reserved.