There appears to be a preconceived notion that the greater the surface area covered, the more efficient the filter performance, which leads to the introduction of extra pockets. Dr Iyad Al-Attar systematically dispels this notion and emphasises the need for a filtration strategy for achieving better Indoor Air Quality (IAQ).

In order for companies to succeed, it is imperative that their mission and vision are well established and goals are set forth to capitalise on the company’s core competencies. Since complex decisions are inevitable, strategic decisions and necessary methods of action for implementation provide a long-term direction to companies. Therefore, the quest for an efficient use of the available resources to ultimately achieve the desired goal is a much-sought-after component of success.

The key word here is “strategy”, which comes from the ancient Greek word, “strategos” meaning military general [1]. In my opinion, perhaps, the most striking definition of strategy is the one stated by Michael Porter: “Competitive strategy is about being different. It means deliberately choosing a different set of activities to deliver a unique mix of values” [2].

Superimposing this definition on filtration, the natural question would be: What can we do differently in air filtration to deliver a unique Indoor Air Quality (IAQ)? A corollary to this would be: Are we considering the relevant parameters to make appropriate decisions? And most importantly, are we equipped with the right tactics to carry out successful filtration strategies?

Establishing relevant parameters

When acquiring a filter, price usually dominates the purchasing tendencies to provide filter solutions to our HVAC applications. Typically, and unfortunately, price seems to steer decisions of selection criterion, far removed from the intended technical ones. In fact, filter performance in the surrounding climatic conditions is not granted the substantial attention it deserves, and human occupants are left to face the consequences.

When acquiring a filter, price usually dominates the purchasing tendencies to provide filter solutions to our HVAC applications. Typically, and unfortunately, price seems to steer decisions of selection criterion, far removed from the intended technical ones. In fact, filter performance in the surrounding climatic conditions is not granted the substantial attention it deserves, and human occupants are left to face the consequences.

Further, parameters such as filter design, surface area, and textbook installation and maintenance measures constitute the foundations of the selection platform. Furthermore, the effect of these parameters might not be very straightforward and, therefore, to avoid inappropriate filter selection, the willingness of managers or other decision makers to consider such parameters is critically important.

The allure of extending surface area

The first selling advantage is filter surface area. Some sales executives tend to start their selling presentation with how their filter can accommodate the largest surface area and, consequently, how other factors will come into play, such as lower face velocity, and its contribution in enhancing the efficiency via extending the particle residence time. But is this always true? Could the addition of uncontrolled surface area become a competitive disadvantage?

The first selling advantage is filter surface area. Some sales executives tend to start their selling presentation with how their filter can accommodate the largest surface area and, consequently, how other factors will come into play, such as lower face velocity, and its contribution in enhancing the efficiency via extending the particle residence time. But is this always true? Could the addition of uncontrolled surface area become a competitive disadvantage?

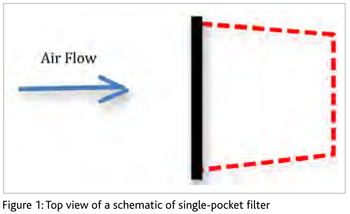

Historically, when the concept of pocket filters came about, the focus was to manufacture a filter with a surface area greater than its frontal area, and a single pocket filter was then introduced, as shown in Figure 1. The number of pockets, then, kept on increasing. Simply stated, the assumption was: The greater the surface area, the better the filter performance.

Here, I would like to pause and analyse this statement. Extending the surface area is not the desired goal while improving the IAQ of a given space. In fact, what is at stake here is providing a surface area that would help in enhancing the efficiency while lowering the pressure drop. In other words, it is not a matter of competition about extra “pockets” or “pleat”. The goal is to introduce additional surface area that actually participates in the filtration process.

It’s not only what you put in it, but also what you leave out

For the sake of illustration – and argument – let’s consider a 592 x 592 mm filter with a single pocket, as shown in Figure 1. Now, let’s consider ways to extend the surface area of such a filter. One way to do it would be to increase the number of pockets. While some would like to extend the depth, others would vote for doing both.

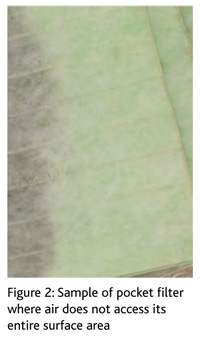

My next question would be: Where would you stop? Would six, eight, 10 or 12 pockets be sufficient? In fact, not because 10 or 12 pockets can actually fit there, it would automatically signify that it would have a positive impact on the filter performance. Once again, the question arises: Is the additional surface area added by virtue of these extra pockets contributing to efficiency enhancement and pressure drop reduction? Before we jump from out of our seats to answer this question, we need to consider whether or not the air is accessing the entire surface area. Figure 2 shows a sample of multi-pocket filter with underutilised filter media.

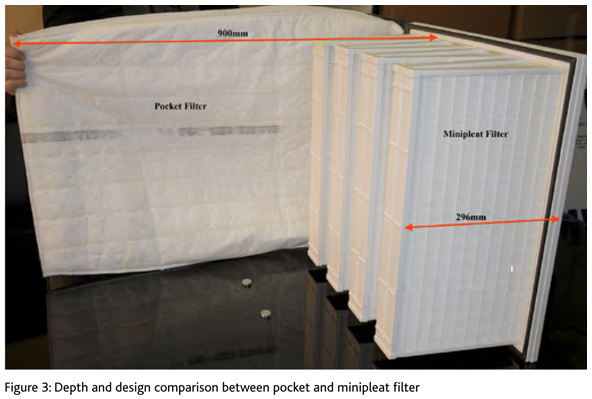

Figure 3 compares a pocket filter with 900 mm depth with a minipleat filter design. When such a filter with a deeper pocket is used, the air-handling unit has to provide greater space to accommodate the filter depth. Further, the deeper the pocket, the greater the vibration of the filter media that may be sufficient to re-entrain previously captured particles into the air stream, resulting in lower efficiency.

Once again, the question remains: Is increasing the surface area by increasing the depth of the pocket and/or the number of pockets the answer to efficiency enhancement? Let’s consider a 10-pocket filter with dimension 592 x 592 x 900 mm, as shown in Figure 3. The total surface area is around 10.6 m2. When compared with the lowest surface area of a minipleat filter, as shown in Figure 3, it has a surface of 20m2 – that is double the surface area of the pocket filter and third of its depth. To match the 20m2 surface area of the minipleat in a pocket filter design, while keeping the number of pockets constant, the pocket depth has to be 1700 mm – a depth which is neither practical from a manufacturing perspective nor useful from a filtration standpoint. Quite simply, the engineering aspect of adding effective surface area is not only about what to put into it, but also about what to leave out.

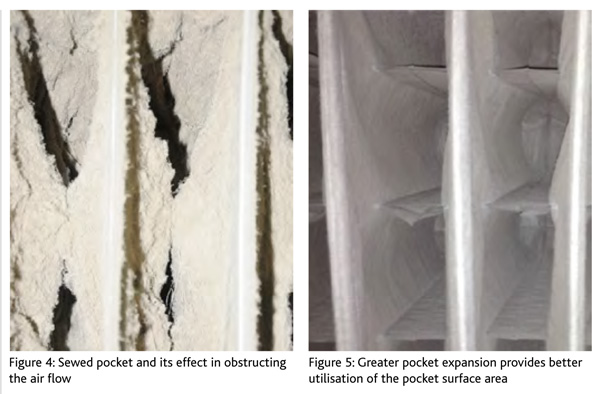

Another parameter to be considered is pocket design. For example, pocket expansion has to be controlled during operation, on one hand, to be accessible by air, and on the other, to avoid over-expansion, which may result in pockets touching the neighbouring ones causing permeability reduction. Different ideas are introduced to do so. Some designers suggest a sewed pocket, as shown in Figure 4, and others provide restrainers in a different manner to better expose the filter media to air with its suspended dust, as shown in Figure 5.

The quest for a filtration strategy

Clearly, the need to have filtration strategies emerges due to the dynamic nature of filtration demands. Careful consideration of filter design and performance are influential parameters in making strategic decisions in filter selection. Ultimately, the strategy needs to help in achieving the best possible efficiency at the lowest pressure drop, given the available resources. However, any strategy, no matter how brilliant, requires the right tactics to implement the means for achievement, which necessitates the prerequisite condition that we confront the truth by asking the following questions:

Dr Iyad Al-Attar is an Air Filtration Consultant. He can be contacted at: iyad@iyadalattar.com

References:

[1] Roberts, John. 2005. “Dictionary of the Classical World”, Oxford.

[2] Gerry, Johnson, Richard Whittington, Kevan Scholes. 2011. “Exploring Strategy”. Ninth Ed. Prentice Hall.

NOTE: Unless otherwise mentioned, all data and images are copyright of the author.

Copyright © 2006-2025 - CPI Industry. All rights reserved.