Pragmatic steps to implementing ASHRAE 241 start with ventilation, says Jeremy McDonald

With ASHRAE’s recent adoption of the first ever infection control standard, “Control of Infectious Aerosols – ASHRAE Standard 241P”, there is finally a standard approach to improved Indoor Air Quality (IAQ), especially with regard to infectious aerosols.

Once implemented, the Standard will, for the first time, establish minimum guidelines for control of infectious aerosols. It also provides a roadmap for clients to meet the guidelines.

In the July 2023 issue, I presented a summary of ASHRAE 241. The topics discussed were:

1. Minimum equivalent outdoor air for infection control rates – prescriptive rates

2. Arrangement for air inlets and outlets

3. Mechanical ventilation guidance

4. Commissioning for infection control

5. Roadmap for assessment, planning and implementation of IAQ for existing facilities

6. Procedure for measuring effectiveness and safety for filtration and air cleaning technologies

7. O&M guidance

8. Systems Manual guideline

In the coming months, I will explore these topics in fuller detail. This column will focus on item 1: “Minimum equivalent outdoor air for infection control”. In my interpretation of the Standard, end-users will need to demonstrate compliance with the current code (ASHRAE 62.1) and start developing strategies to increase the provision of clean air.

Background

Building code has long prescribed minimum airflow for various spaces. ASHRAE 62 has long been the guiding standard for design engineers and HVAC professionals regarding the minimum airflow for various spaces.

ASHRAE Standard 62.1-2019 (Ventilation for Acceptable Indoor Air Quality) establishes the minimum amount of ventilation air (required by building code) for a space/building. The Standard has long provided formulae to calculate the required outdoor ventilation as a function of space usage, number of occupants and space size.

Jeremy McDonald

While ventilation standards are based on years of research, best practices and the collective wisdom of previous standards, too often the actual amount of ventilation air in buildings falls short of the Standard. As discussed in previous articles, common issues which occur in building operation are:

1. Spaces use conversion: Over time, spaces are converted in use, which may compromise HVAC. For example, converting a storage space to an office will require the addition of ventilation. If overlooked, owing to ignorance or practicality, this can lead to sub-standard IAQ.

2. Routine maintenance: HVAC equipment needs routine maintenance to ensure performance. Belts, fans, motors and dampers are just a few of the many items that require maintenance for a consistent operating system.

3. Unintended consequences: Modern HVAC is reliant on direct digital control systems (DDC) for most facilities. The failure of monitoring devices – temperature sensors, dampers, etc. – can lead to the DDC system unintentionally causing an HVAC system to erroneously operate. We have witnessed systems that shut down outdoor air dampers due to failed sensors or to operator error.

4. Desire to save money: Outdoor air is expensive. By overriding outdoor air dampers and/or forcing dampers shut, building operators can reduce the amount of utility cost needed to condition the air, often to the detriment of the unsuspecting occupants of the building space.

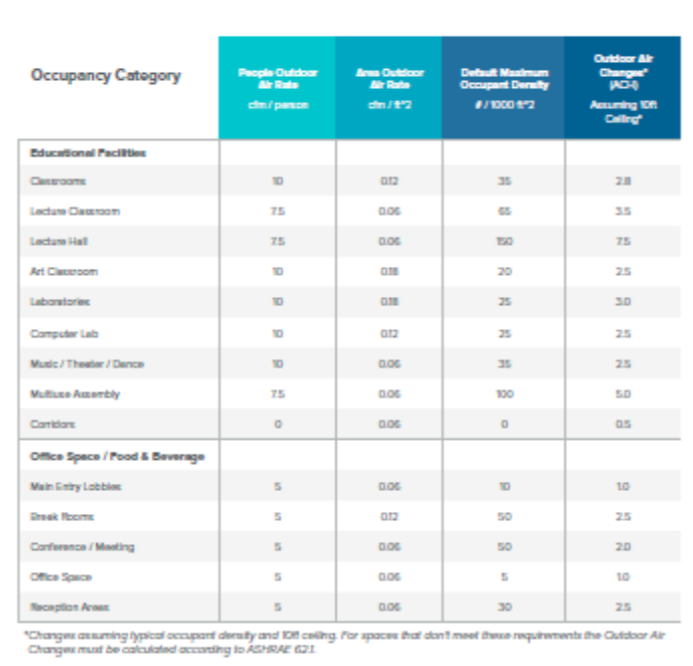

Using a school building as an example, ASHRAE provides guidance for a diversity of spaces. The table, below, indicates the minimum outdoor air changes, as recommended by ASHRAE Standard 62.1 – 2016: Ventilation Rate Procedure for typical higher education spaces (assuming 10 feet ceiling height).

It is important to note that ASHRAE 62 prescribes a method for calculating the minimum required airflow for a space as a function of the number of occupants and also the size of the space. For a typical office or classroom, adjusting for the contribution for square footage for a space will add about 30% to the outdoor air rate for people alone. For simplicity (please see table, above), the “people airflow rate” (2nd column) for a classroom is 10 cfm/per person. Taking into account the area outdoor air rate (third column) will add 3 cfm/per person, for a total of 13 cfm/person. The new ASHRAE 241 will require a significantly higher amount of clean ventilation air, which is unlikely to be supplied by provision of outdoor air alone.

ASHRAE 241: A new way of thinking

ASHRAE 241 introduces new concepts, which I believe will have significant consequences for the HVAC industry and the operation of buildings. These concepts include:

Building Readiness Plan (BRP)

A custom plan for a building, which documents the engineering and non-engineering controls for a facility to achieve its goals with regard to infectious risk.

Infection Risk Management Mode (IRMM)

The mode of operation when the BRP dictates that the building occupants are at greater risk of infectious disease.

Minimum Equivalent Clean Airflow Rate

Although similar in structure to the ASHRAE 62 method of calculating the minimum outdoor airflow rate, ASHRAE 241 specifically takes into account the contribution of filtration and air cleaning devices.

The minimum equivalent clean airflow rate is much higher than outdoor air levels required by ASHRAE 62. For a classroom, ASHRAE 62 requires approximately 13 cfm/person, whereas ASHRAE 241 will require 40 cfm/person.

Increasing the amount of fresh air by a factor of 3 isn’t possible for many systems, and will drive energy cost and carbon emissions to very high levels.

ASHRAE does not require end-users to needlessly increase ventilation for all time periods, just when the building and its occupants are most at risk. The Standard properly recognises that there are certain time periods when the conditions for viral spread are more likely. The BRP will be the tool for decision-makers to decide when a building is designated as IRMM. When this occurs, building managers will be required to increase the airflow levels to the levels prescribed by ASHRAE 241.

In addition, the minimum equivalent outdoor airflow rate can rely on both air cleaning technologies and improved filtration. The Standard allows for calculation of air cleaning of recirculated air and also the use of mechanical in-room air cleaners and filters. This way, facility managers can use temporary technologies, either in ductwork or adding to the space to avoid cost retrofits and unmanageable increased energy cost.

For most buildings that have reasonably maintained and updated HVAC systems, adding improved filtration and air cleaning will be able to meet the intent of ASHRAE 241’s IRMM with a reasonable cost. Adding MERV 14 filters, which have become standard for office buildings and most institutional buildings, is a small marginal cost, and can go a long way to meet the IRMM. Air cleaning, which I will discuss more in my next column, could be quite expensive but would be marginally less than a capital investment for new HVAC systems.

For buildings that have antiquated systems or severely deferred maintenance, the cost of meeting the IRMM may be quite high. It is important to note that if a building owner needs to make a large capital investment in HVAC, they were probably not meeting the intent of current building codes, which are largely based on ASHRAE 62.

Takeaways

ASHRAE 241 is intelligently written and well structured to provide the proper improved delivery of clean air for infectious control periods, without forcing clients to make costly investments – in most cases. For buildings that have significantly deferred maintenance, the investment cost may be high. However, these buildings are probably at the highest risk, and should be fixed to avoid future “super spreader” type events.

Senior care facilities, which serve a critical role in the care of our elders, come to mind as the building sector that may need the most help. With many senior care facilities already struggling financially, adding punitive financial investment requirements through capital upgrade may have negative consequences for this particular building sector. The approach for this most critical of health care providers needs to be thoughtfully planned by our decision makers. The time to deliberate is now, before the next infectious control issue and/or pandemic is upon us.

Jeremy McDonald is a principal of Guth DeConzo Consulting Engineers, in New York. Before the pandemic, he was an adjunct professor at Rensselaer Polytechnic Institute. Recently, he was the technical consultant to the New York State Energy Research and Development Authority in development of an IAQ guideline for Higher Education in NY: “Covid-19 Response Guide, State University of New York”. He may be reached at jmcdonald@guthdeconzo.com.

Copyright © 2006-2025 - CPI Industry. All rights reserved.