That’s how Prashanth B S characterises the decision to use LED lighting technology, which he proves through metrics as having a substantial reduction in the cooling load of a building.

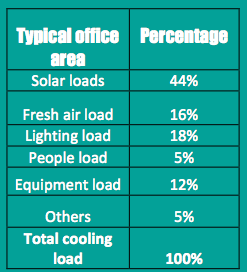

Lighting load represents approximately 18% of the total cooling load in a typical office or commercial building (see table, below). Bringing changes in the lighting will have a direct and indirect impact on the capex and opex of the building, including a major impact on the air conditioning system.

EVOLUTION OF LIGHTING

Light bulbs have experienced an evolution over the years, which has allowed the same lumen output to be obtained for a lower watt input. From incandescent light bulbs to LED light bulbs, the luminous efficacy has become nearly 10 times higher, which means that LED lamps can save up to 90% of the energy compared with incandescent lamps. Although incandescent lamps have largely been phased out by energy codes in developed countries, they are still widely used in several parts of the developing world.

Lighting systems convert only some of their electrical input into useful light output. Much of the rest is released directly as heat into the space.

A heat sink is built outside the body of the lamp. This provides a passive cooling element, which helps the lamp release heat into the surroundings, preventing damage to the lamp from high temperatures. Typically, a heat sink is composed of a finned surface that increases the effective area of contact with the air, hence increasing heat transfer. Any upgrade of the lighting system that reduces input wattage reduces the amount of heat that must be removed by the air conditioning system. This results in air conditioning-related energy savings during the operation of the building. In new construction, an energy-efficient lighting design can result in significant savings in the installed cost of cooling systems.

The effect on air conditioning loads can be considerable when lighting systems are changed. For every 1,000 watts of lighting heat reduction, cooling loads are reduced by 3,412 BTU/hour. In a building with hundreds of lamps, several tonnes worth of air conditioning capacity may be saved by installing a more efficient lighting technology.

LED lamps offer the highest luminous efficacy and lifespan of all commercial light bulb options. They tend to have a moderate to high price but can save about 80% of the energy when compared to incandescent alternatives and about 50% of the energy when compared to fluorescent options. An additional advantage of LED lamps is that their heat footprint is extremely small, providing indirect energy savings by reducing air conditioning loads.

Consider an operational 100,000-square-foot G+12 commercial office building. At two watts per square foot design for lighting load, and operating at 3,120 hours per year (52 weeks with five days and 12 hours per day of operation), the lighting demand and consumption can be calculated by:

If you consider an LED alternative that replaces the current lamps and provides 50% savings:

Comparison

This scenario only considers direct energy savings from the lighting upgrade. There is also air conditioning savings, thanks to the reduction of the heat released by the lighting system. A quick and reasonable estimate can be calculated from the lighting load reduction and the average efficiency of the air conditioning system; however, a detailed energy audit will provide better estimates.

Assuming the air conditioning system operates with a COP of 1.758 (2.0kW/tonne), the total savings achieved per year would be:

This brings total energy savings (total kWh savings) to 312,000 kWh/year + 177,474 kWh/year = 489,474 kWh/year.

THE SAVINGS IN AED (ARAB EMIRATES DIRHAM)

For new construction, if we assume DEWA electricity demand or connection fee is AED 1,000/kW, and for existing buildings the consumption charges to be AED 0.38/kWh, the savings would be:

INDIRECT SAVINGS

LED lighting also provides indirect savings during both project construction and operation:

CONCLUSION

Overall, most energy-efficient lighting upgrades in commercial buildings equate to a positive gain by reducing total energy consumption. If there is a large building with large internal loads and high usage of air conditioning, it is possible to see approximately 40% reduction in HVAC by adopting a more energy-efficient lighting system. In addition, using daylight to save energy on indoor lighting and utilising daylight harvesting and optimising the lighting requirements and using technology, such as motion sensing, can result in substantial savings in lighting, air conditioning and power.

____________________________________________________________________

Prashanth BS is the Associate Vice President, Air Conditioning Business Group and Lighting & Electricals Business Group, Eros Group. He can be contacted at prashanth.bs@erosgroup.ae.com.

____________________________________________________________________

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Copyright © 2006-2025 - CPI Industry. All rights reserved.