Danfoss

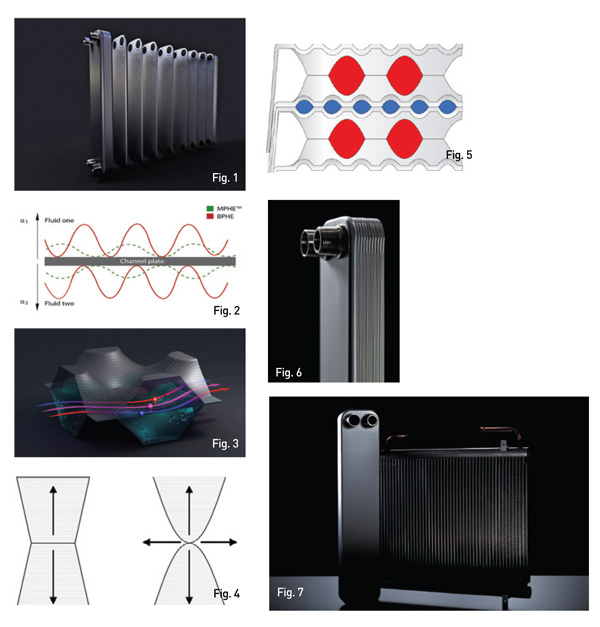

Stating that conventional solutions are failing to meet the increasing demands for efficiency and sustainable development, Danfoss says it has developed a new technology – the Micro Plate Heat Exchanger (MPHE) (see Figure 1 below). The company says MPHE technology is setting new standards in energy efficiency, with significantly improved heat transfer, reduced use of raw materials and minimal hold-up volumes translating into clear economic and environmental savings. The unique dimple-plate pattern makes the MPHE more robust, Danfoss claims.

It says the dimple technology is the main driver for the MPHE’s higher efficiency, offering far better heat transfer, because the flow around the brazing points is more uniform. According to the company, laboratory tests show that the difference between the maximum and minimum velocities in an MPHE is only one-third of the ratio in a traditional BPHE (see Figure 2 below). The MPHE achieves an optimal balance between increased turbulence and frictional losses, significantly increasing the heat transfer coefficient and improving efficiency (see Figure 3 below).

The company says traditional BPHEs have their brazing points in fixed, regular locations across the plates. In the MPHE, the position of each brazing point can be determined individually. This means brazing points can be concentrated in areas subject to higher mechanical forces. Strength is further increased by the dimples themselves, which offer a greater contact area (see Figure 4 below).

This freedom in the positioning of brazing points also offers opportunities to design solutions totally dedicated to the needs of different applications. According to Danfoss, alongside universal models, MPHEs are already available in dedicated ranges for heat pump and chiller applications respectively.

MPHEs have lower hold-up volumes compared with traditional BPHEs and the heat exchanger is also simply smaller, reducing the refrigerant charge by up to 40%, the company says. This represents a core saving on the initial refrigerant charge, but the need for refills also has a significant impact on running costs. For a typical heat pump (60 kW), the savings on refrigerant amount to EUR 120 per year – before taxes, it is claimed.

Danfoss says the MPHE technology requires less raw material and thus, a lighter unit can be used for a given capacity. In turn, this makes the price of MPHEs less sensitive to increases in raw materials costs. For chillers, the value of the increased stability ranges from EUR 30 (160 kW) to EUR 55 (400 kW) annually, the company claims.

The versatility of the MPHE’s dimple technology offers great freedom in exploiting asymmetrical flows, says Danfoss. MPHEs can achieve asymmetry ratios as high as 1:27, which allows the asymmetrical flow to be adapted precisely to the given operating conditions (see Figure 5 below), the company adds.

An MPHE is manufactured in the same way as a traditional BPHE, following a well-proven manufacturing process, Danfoss says. Typically, the same pressure vessel codes – including PED, UL/CSA and KHK – apply. MPHEs are the preferred technology for a number of leading European heat pump and chiller manufacturers (see Figure 6 below).

Copyright © 2006-2025 - CPI Industry. All rights reserved.