Dan Mizesko elaborates on the importance of proper chiller evacuation, dehydration and the Standing Vacuum Test

A conventional centrifugal chiller is designed to operate with oil and refrigerant flowing internally. Anything else in the system is considered contamination and must be removed. This includes moisture and non-condensable gases, such as air. Proper start-up, commissioning and ongoing service practices are the first steps in keeping a system clean.

At sea level, one atmosphere exerts a pressure of 14.696 psi (pounds per square inch) or 29.921 in. Hg (inches of mercury). At this pressure, a calibrated compound pressure gauge will read 0 psig (pounds per square inch gauge). This pressure is referred to as Standard Pressure and is equal to one atmosphere (psia).

Dan Mizesko

At this pressure, pure water boils at 212 degrees F. If we were to move our container of pure water to an altitude higher than sea level, say 5,000 feet above sea level, the water will boil at 203.4 degrees F, since the atmosphere exerts approximately 25 in. Hg, 12.278 psi or 0.835 psia.

If we were to increase the pressure on the container of pure water to 15 psi or 30 psia, which is above standard conditions, our boiling point will rise to 250 degrees F, because the boiling point of water can be changed and controlled by controlling the vapour pressure above the water.

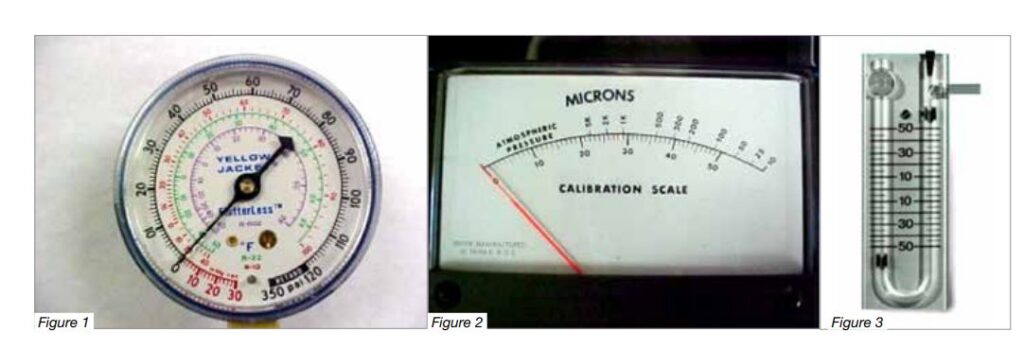

This is known as the Pressure-Temperature Relationship. In Figure 1, there are two pressure scales on the face of the gauge. Above 0 is the scale for measuring positive pressure or pressure above one atmosphere in pounds per square inch. The scale below 0 is used to measure negative pressure or pressure below one atmosphere in inches of mercury.

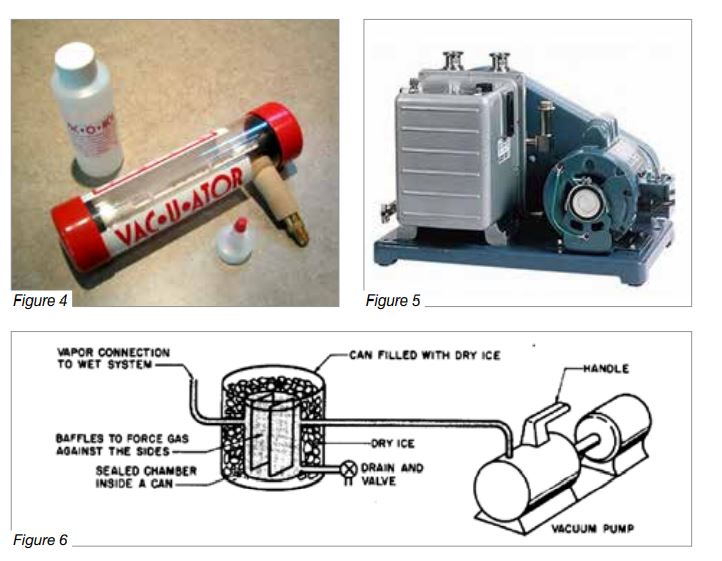

This scale is accurate up to 29 inches of mercury. Vacuum levels between 29-inch Hg and 30 inch Hg (absolute vacuum) are measured in microns. One thousand microns are equal to one millimeter of mercury and are measured with an electronic vacuum gauge.

If we were to reduce the internal pressure of a chiller to 29 inch Hg, we can say we have evacuated the system, meaning that we have removed air and non-condensable gases; and in doing so, we have lowered the boiling point of any remaining moisture in the system; but we have not dehydrated the system, if moisture remains.

By attaching an electronic micron gauge to the system, we can measure the vacuum level between 29 and 30 inches of mercury. The scale of the electronic micron gauge ranges from 0 to 5,000 microns. As we continue to extract molecules of vapour from the system with a vacuum pump, the decrease in pressure will register on the micron gauge. Conversely, if we were to stop extracting molecules of vapour and allow the system to remain static, no rise in pressure will be noted on the micron gauge, provided the system is completely sealed and dehydrated and no moisture is present. If moisture is present, a notable rise in pressure will be seen on the micron gauge, as liquid moisture boils off into vapour. Vacuum can also be measured with a U-tube mercury manometer.

The device has a glass U-tube, graduated in inches of mercury. One end of the U-tube is connected to the system and the other end is open to the atmosphere. When the internal pressure of the system is equal to atmospheric pressure, the mercury level in the side open to the atmosphere is equal to the side connected to the system. As the system pressure decreases, so does the level open to the atmosphere. A wet bulb vacuum indicator can also be used and proves very accurate in the absence of a micron gauge.

The device in Figure 4 uses Methyl Alcohol Anhydrous, which is poured through a fitting provided at the top of the cylinder. It is common practice to fill to the middle of the lower port and connect the Wet Bulb Indicator to the evacuation line. It should be evacuated until the wet bulb thermometer reads –32 degrees F.

A chart is provided to convert wet bulb temperature to microns. As we have covered several methods of measuring a vacuum, let’s now discuss the equipment required to achieve the vacuum.

The vacuum pump must be a high-capacity minimum 20 CFM pump to evacuate and dehydrate a large chiller in a reasonable period of time. It must be in good operating condition, leak free and clean. It is important to change oil prior to every use.

Besides providing pump lubrication, the oil provides an internal seal. Clean fresh oil is a must. It is advisable to follow the pump manufacture’s maintenance instructions. It is equally important to use good-quality hoses and be sure that they are free of cuts and blemishes and that they do not leak. Also, it is recommended to use copper tubing instead of hoses, whenever possible.

Putting it all together – evacuation, dehydration, Standing Vacuum Test

A note of caution: Do not start or megohm-test the compressor motor or oil pump motor, even for a rotation check, if the chiller is under dehydration vacuum. Insulation breakdown and severe damage may result on doing so. To be safe, isolate any starter before evacuating the chiller if you are not sure if there are live leads to the hermetic motor.

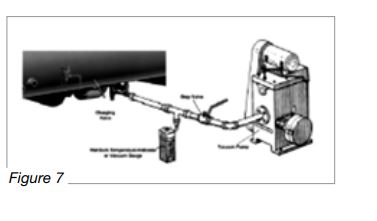

The following steps are recommended if the chiller has been open for a considerable period of time, if the chiller is known to contain moisture, or if there has been a complete loss of chiller charge. Evacuation and dehydration can be performed at room temperatures. Using a cold trap (Figure 6) may substantially reduce the time required to complete the dehydration. The higher the room temperature, the faster dehydration takes place.

The following procedures are for high-pressure centrifugal chillers:

1) Dry nitrogen purge. This is done by connecting a nitrogen cylinder to the chiller in a manner that will permit a low-volume purge to remove as much moisture as possible. It is advisable to drain as much water as possible, paying close attention to all the low points. One pound of water, which is approximately one pint, will produce 2,948 cubic feet of water vapour.

2) Connect a high-capacity vacuum pump (20 cfm or larger is recommended) (Figure 7) to the refrigerant charging valve. Tubing from the pump to the chiller should be as short in length and as large in diameter as possible to provide least resistance to gas flow.

3) Use any of the instruments described in this article to measure the vacuum. Open the shut-off valve to the vacuum indicator only when taking a reading. Leave the valve open for three minutes to allow the indicator vacuum to equalise with the chiller vacuum.

4) With the chiller ambient temperature at 60 degrees F (15.6 degrees C) or higher, operate the vacuum pump until a wet bulb temperature of 0 degree C or a pressure of 5 mm Hg (absolute) is reached. To improve evacuation, circulate warm water (not to exceed 50 degrees C) through the cooler and condenser tubes to thoroughly dehydrate the shells. If a source of hot water is not readily available, it is advisable to employ a portable water heater. Do not use steam, under any circumstances. A suggested method is to connect a hose between the source of hot water under pressure and the cooler head drain connection, out the cooler vent connection, into the condenser head drain and out the condenser vent. To avoid the possibility of causing leaks, the temperature should be brought up slowly so that the tubes and shell are heated evenly.

5) Valve off the vacuum pump, stop the pump and record the instrument reading.

6) Standing Vacuum Test.

Hold the vacuum in the system for eight hours; the slightest rise in pressure indicates a leak or the presence of moisture, or both. If, after eight hours, the wet bulb temperature in the vacuum indicator has not risen above 4.4 degrees C or a pressure of 6.3 mm Hg, the system may be considered tight. 7. If the vacuum does not hold for eight hours within the limits specified, the leak must be found and repaired. If you follow these procedures, you will be assured your chiller is moisture free, leak free and ready for operation.

Dan Mizesko is Managing Partner/ President, U.S. Chiller Services International. He may be contacted at dmizesko@uscsny.com

Copyright © 2006-2025 - CPI Industry. All rights reserved.