UK-based multi-university initiative aims to research and develop tools to locate, position and digitally record all buried utilities.

Locating buried infrastructure for utility management, especially in crowded urban environments, is a challenge, as existing techniques have limitations. Now a UK-based multi-university, multi-disciplinary initiative aims to research and develop tools to locate, position and digitally record all buried utilities in all ground conditions in the country. The project, when completed, could have far- reaching implications.

It is estimated that there are enough pipes and cables buried within the UK that, if laid end to end, would stretch to the moon and back 10 times. These buried pipes and cables provide the principal means to supply power, gas, telecommunications and clean water, as well as remove foul water and, as such, are vital to modern living. They require regular maintenance and, occasionally, require emergency repair in the event of failure, to maintain their function. New sections of pipeline are often added to the existing networks to ensure that the utilities can cope with increasing demand. Without careful control of these networks, the disruption in supply can result in the breakdown of modern living (as illustrated by the outbreak of cholera in Zimbabwe in 2008 due to poor control of sewage and potable water supply networks, BBC, 2008).

It is estimated that there are enough pipes and cables buried within the UK that, if laid end to end, would stretch to the moon and back 10 times. These buried pipes and cables provide the principal means to supply power, gas, telecommunications and clean water, as well as remove foul water and, as such, are vital to modern living. They require regular maintenance and, occasionally, require emergency repair in the event of failure, to maintain their function. New sections of pipeline are often added to the existing networks to ensure that the utilities can cope with increasing demand. Without careful control of these networks, the disruption in supply can result in the breakdown of modern living (as illustrated by the outbreak of cholera in Zimbabwe in 2008 due to poor control of sewage and potable water supply networks, BBC, 2008).

The traditional construction techniques associated with maintenance or installation of buried utilities in the UK utilise open-cut methods. The principal advantages of open-cut techniques are that construction workers can see what they are dealing with and have space, even if limited, in which to work. However, open-cut methods damage the carriageway, potentially damage adjacent utilities during excavation and disrupt society’s functions (congestion caused by street works is considered a major problem within the UK). It is estimated that up to four million holes are dug in the UK road network each year to install, or maintain existing utilities. Written records describing the location of buried utilities are often imprecise or wrong, leading to frequent failure to locate the desired utility (known as dry-holes). A report published by McMahon et al. (2005) estimated that street works associated with utility management cost the UK economy £7 billion annually (£1.5 billion in direct costs and £5.5 billion in disruption to society’s function).

Alternatives to trenching do exist: geophysical detection techniques can be employed to locate utilities without the need for excavation, and trenchless technologies can be used to refurbish or install new utilities. However, these are not commonly used in preference to open-cut trenching, due to perceived limitations associated with the techniques.

An investigation into geophysical performance was undertaken by Ashdown (2001), with geophysical location companies being invited to survey a test site where the locations of the buried utilities were known. An 80% detection rate, at best, was returned. It is not suggested that detection rates would still be at the same level nearly a decade on.

And there clearly has been improvement in technology and surveying practices. However, a desired 100% detection rate in all ground conditions, using geophysical techniques, is still beyond current means.

The inability to locate all buried infrastructure, effectively results in installations being conducted using trenchless technologies that can disturb the ground, without full knowledge of what is buried below. This raises the level of risk associated with utility strikes and makes the trenchless techniques less appealing than open-cut methods.

Mapping the Underworld (MTU) is a UK-based multiuniversity, multi-disciplinary research initiative that aims to research and develop the tools necessary to achieve the location, positioning and digital recording of 100% of the buried utilities in all ground conditions. It is envisaged that the successful completion of MTU’s aims will promote the adoption of geophysical detection techniques and trenchless technology installation/ maintenance techniques when working in the street.

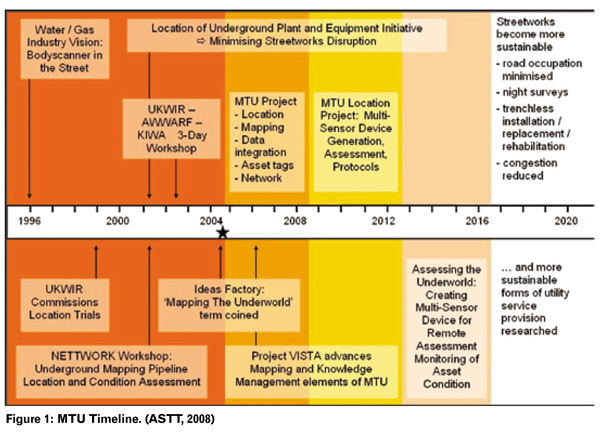

The MTU initiative commenced in 2005, and has a 15-year programme (Figure 1). The first phase of the project (2005-2009) comprised four research projects: a study investigating the feasibility of a multi-sensor platform; methods to determine the position of utilities using surveying methods, even in crowded urban environments; development of a common format for a cross-utility company electronic records database; and resonant tags that increase the likelihood for detection of utilities fitted with the tags when using ground-penetrating radar (these tags can be retrofitted to existing pipes during maintenance cycles or built into the walls during the construction of new pipes). Each of these projects has received further funding. (See Figure 1).

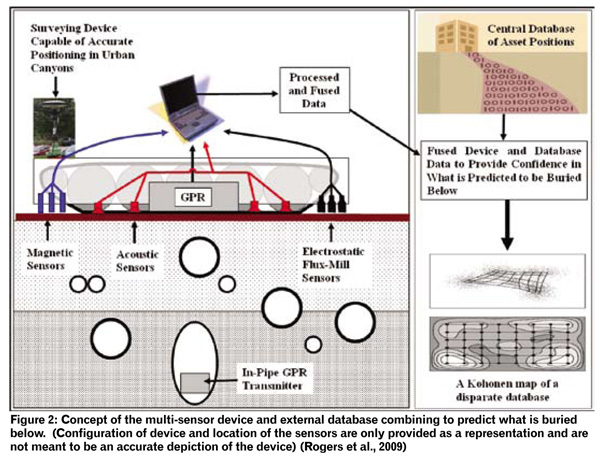

In 2009, the MTU Location project (development of a multi-sensor platform) received £3.5 million in funding from the UK’s Engineering and Physical Sciences Research Council to research and develop a multi-sensor platform. This platform will utilise four location technologies: ground-penetrating radar (GPR), vibro-acoustics, lowfrequency electromagnetic and passive magnetic fields. Two of the location techniques (GPR and vibro-acoustics) are being optimised for the project, whilst the remaining location techniques are being developed from first principles. The four location technologies have been selected, as no single technique has the potential to detect all buried utilities in all ground conditions (when considering the sheer range of variations in possible burial depths, pipe materials and ground conditions that could be encountered on site), whereas the four location techniques operating in conjunction might.

To improve detection rates still further, and reduce the impact of ground conditions on the location techniques, the potential for the development of in-pipe sensors – to work in conjunction with the surface mounted multisensor platform – for GPR and vibro-acoustic techniques is being investigated (Figure 2). Preliminary testing of the combined locating technologies is due to commence in the summer of 2010. (See Figure 2)

The multi-sensor device is being developed on a principle that it should not be used in isolation. Additional sources of information for a site due to be surveyed are likely to exist, and these should be incorporated into the surveying process to ensure that every opportunity is exploited to locate all of the buried utilities. For example, records for the utilities found on a site are often available and the ground conditions on site are known, or can be derived.

Research is being undertaken to fuse the data from the four sensors with existing electronic location records for the site being surveyed (should they exist), thus providing an additional data feed to increase the confidence in the location of the buried utilities. Discrepancies can be used to inform additional data analysis, to increase detection rates to 100%, or if it is found that the records are incorrect, then the data from the multi-sensor device can be used to update the electronic records. Additionally, research is being undertaken to identify the relationship between the geotechnical and geophysical properties of the ground. The understanding generated will be used as a foundation for a ‘knowledge-based system’ (KBS) that is being developed to help inform the surveyor of the ground conditions on site and their effects on the geophysical signals.

The KBS is based on the electronic records regarding the ground conditions within the UK (parent rock, soils, pore water chemistry, etc) held by the British Geological Survey. It will utilise the understanding of the interaction between the soil and the geophysical signals and the change in soil properties with changes in season (also being developed in the project), to inform the surveyor and allow the optimisation of the deployment strategies for the individual sensors and the optimisation of data analysis.

References :

Ashdown C. (2001). Mains Location Equipment A State of the Art Review and Future Research Needs – Final Report. UK Water Industry Research, London, UKWIR Report Number: 01/WM/06/1, ISBN: 1 84057 233 7

ASTT (2008) Utility Location: Mapping the Underworld: Locating Buried Assets Without Excavation. Trenchless Australasia, Published by Great Southern Press of behalf of the Australasian Society for Trenchless Technology, October 2008 pp. 40-42

BBC (2008). Water crisis hinders cholera fight. Online article posted on Wednesday, December 3, 2008. Last accessed June 2010, for further information please see: http://news.bbc.co.uk/1/hi/world/africa/7761520.stm

McMahon W., Burtwell M.H. and Evans M. (2005). Minimising Street Works Disruption: The Real Costs of Street Works to the Utility Industry and Society. UK Water Industry Research, London, UKWIR Report Number: 05/ WM/12/8, ISBN: 1 84057 408 9.

Rogers C.D.F., Chapman D.N., Royal A.C.D. and Metje N. (2009). The Mapping The UK Underworld Project. Proceedings of the International No-Dig Show 2009 Toronto, Ontario Canada March 29 – April 3, 2009

The article has been jointly compiled by the following: Royal, A.C.D1., Rogers, C.D.F1, Atkins P.R.2, Brennan, M.J.3, Chapman, D.N.1, Chen, H. 4, Cohn, A.G.4, Curioni, G.1, Foo, K.Y2, Goddard, K.5, Hao, T.1, Lewin, P.L.5, Metje, N.1, Muggleton, J.M.3, Naji, A.6, Pennock, S.R.6, Redfern, M.A.6, Saul, A.J.7, Swingler, S.G.5 and Wang, P. 5.

1 School of Civil Engineering, University of Birmingham

2 School of Electronic, Electrical and Computer Engineering, University of Birmingham

3 Institute of Sound and Vibration Research, University of Southampton

4 School of Computing, University of Leeds

5 School of Electronics and Computer Science, University of Southampton

6 Department of Electronic and Electrical Engineering, University of Bath

7 Department of Civil and Structural Engineering, University of Sheffield

If you want to get in touch … MTU (www.mappingtheunderworld.ac.uk) is a collaborative research project, benefiting from the generous input and involvement from its many industry partners.

Copyright © 2006-2025 - CPI Industry. All rights reserved.