In the seventh part of the series on air filtration, Iyad Al-Attar explains how to strike the right balance between the best efficiency rate and the lowest pressure drop

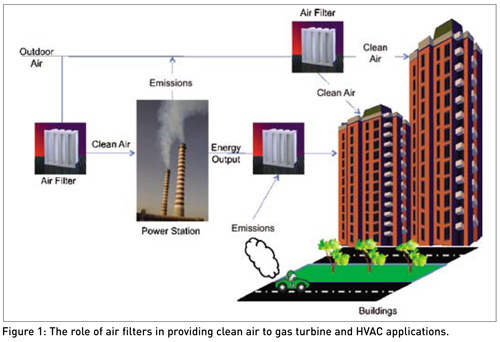

The rising public concern regarding indoor air quality in residential and commercial buildings has led to major developments of high efficiency air filters. The role of air filters in providing clean air in our daily human and industrial activities can never be emphasised enough. A large mass of clean air must be supplied to operate a gas turbine to generate energy for our buildings. Further, Heating, Ventilation and Air Conditioning (HVAC) systems also require clean air to introduce to the indoor spaces. Therefore, in both cases, as illustrated in Figure 1, air filters are absolutely essential to grant the air clean in quantity and quality required.

Walking on a rope

Ideally, we strive to have a filter with the best efficiency and the lowest pressure drop. It feels though like walking on a rope, improving the efficiency usually is associated with an increase in the pressure drop, and lowering the pressure drop will negatively impact the filter efficiency. The ultimate objective while walking on this rope is saving energy and providing the indoor air quality (IAQ) required. The “over-the-counter” solution would be sacrificing the efficiency by installing a lower pressure drop filter. By doing so, the IAQ is compromised but one would argue that more energy is saved this way. This sort of argument may seem logical and easier to quantify, present and possibly even convince building owners and operators. However, lowering the IAQ as a result of selecting lower filter efficiency requires harder effort to quantify and additional sampling devices to measure IAQ.

Everyone admits cost is always an issue when it comes to any engineering process. However, compromising filter efficiency in exchange for lower pressure drop is a rather risky measure and exposes the HVAC system and the human occupants to greater pollution level. We need to alter the angle at which we approach the air filter selection according to each application. No one wants to consider the commercial viability of an air filter prior to considering its performance credibility. Higher exposure to fine particles has been linked to lung cancer and cardiopulmonary illness1. Asthma attacks can be triggered by particulate matter (PM) and tobacco smoke has been related to health effects including aggravation of respiratory system1.

Filter lifetime

Usually the filter lifetime of the filter is based on its final pressure drop. Surely, it would make great sense to consider low-to-medium efficiency filters. But how about absolute filters? These filters are subject to low particle concentrations which means it would take months or even years before they reach their final pressure drop. An important consideration at this stage is microbial growth on HEPA filters during operation and to prevent it from transporting to the clean segments of the building. When greater IAQ is required, using the final pressure drop as the only means of replacement may not be always appropriate.

Urban Air Quality

Emission reduction traces back to 1272 when King Edward I of England banned the burning of sea-coal in London as smoke had become a critical problem2. In the seventeenth century, the effects of acidic pollution were noted on vegetation and humans although “acid rain” only came in context when Angus Smith published his book “Acid Rain”. In the late 1960s, air quality fell under the scientific knife but emphasis was still placed on outdoor pollution. Early 1970s indoor air quality was investigated by scientists to study the complaints of human exposure2. Nowadays, HVAC systems extensively use outdoor air to introduce clean air to the indoor spaces and therefore, the role of air filters becomes critically important in contaminant removal.

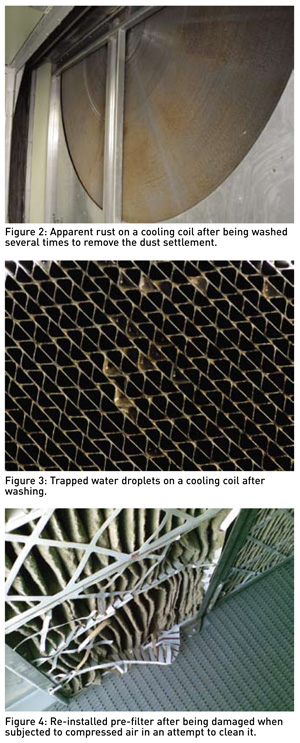

Clearly, outdoor air requires conditioning prior to introducing it into our indoor spaces, but prior to allowing outdoor air to enter our HVAC equipment we must first filter it. While the pollutants and their effects constitute a long list, indoor pollutants are not to be underestimated. We frequently tend to blame the atmosphere of emitting pollutants (particulate matter, fungal spores, pollen, jet engine and traffic exhaust) capable of penetrating our buildings. In fact, indoor sources such as cooking, tobacco smoking, vacuuming and cleaning can also play a role in the emission process. Therefore, a thorough understanding of indoor particle sources and their emission contribution is absolutely essential in enabling exposure control and reduction measures. Further, the manner in which air handling units’ maintenance is conducted, such as coiling washing (Figure 2 and 3) and attempting to regenerate a depth (disposal) filter (Figure 4), increases the possibility of contamination and worsening of air quality.

Clearly, outdoor air requires conditioning prior to introducing it into our indoor spaces, but prior to allowing outdoor air to enter our HVAC equipment we must first filter it. While the pollutants and their effects constitute a long list, indoor pollutants are not to be underestimated. We frequently tend to blame the atmosphere of emitting pollutants (particulate matter, fungal spores, pollen, jet engine and traffic exhaust) capable of penetrating our buildings. In fact, indoor sources such as cooking, tobacco smoking, vacuuming and cleaning can also play a role in the emission process. Therefore, a thorough understanding of indoor particle sources and their emission contribution is absolutely essential in enabling exposure control and reduction measures. Further, the manner in which air handling units’ maintenance is conducted, such as coiling washing (Figure 2 and 3) and attempting to regenerate a depth (disposal) filter (Figure 4), increases the possibility of contamination and worsening of air quality.

Particle Size Significance

Particle size are graded according to their health effects and size selective sampling and usually referred to as Particulate Matter (PM)2. PM range is selected based on the particles ability to reach a specific part of the respiratory system. Particles which can enter nose or mouth are referred to as the inhalable fraction. If particles can reach the thorax, it is then referred to a thoracic fraction. Respirable fraction on the other hand, contains particles capable of reaching the alveolar region of the human respiratory system but do not necessarily deposit there2. It commonly found that PM2.5 and PM10 are used when air quality and pollutions are addressed. While PM10 is similar to the thoracic fraction, PM2.5 can easily make their way through indoor spaces and poses a critical component of indoor exposure2.

To add to the complexity of the air filters assessment, building design can also influence indoor pollutant concentrations and filter performance, some of these factors are listed below:

The main filter characteristics for air filter performance are pressure drop and efficiency. As filters are loaded with dust, these characteristics change due to alteration in the internal structure of filter. Finally, the filter reaches a “clogging point” which is still a loosely defined term.

Perhaps we could be so abstract in assessing the performance of air filters in HVAC systems. To avoid passing judgment on such a critical issue, it is rather important to highlight the factors we ought to consider when evaluating the air filtration performance in general in the giant HVAC system:

Clearly, it is not a pass or fail examination so to speak when addressing such crucially important assessment. Air filters are expected to remove airborne particles, microorganisms and gaseous contaminants from the air stream and is characterised by its efficiency and air flow resistance. However, to ensure that air filters will perform according to the test reports that accompany them, a better understanding of the methodology of testing is required to be in a position to fairly evaluate its performance.

A contamination barrier, not a carrier.

Air filtration demands perfection. Simply put, filters are sought and bought to protect equipment and human occupants, if any of the associated performance requirements is missing, air filters can become a pollution carrier instead of a contamination barrier.

No looking back

We seem to always be looking back at conventional techniques to operate our HVAC systems. Conventional on/off thermostat merely based on temperature rather than on the daily human activities and requirements, single flow rate fan running day and night whether or not the indoor space is occupied, washing the heating/cooling coil rather making appropriate selection and leakage-free installation, seeking single stage filtration using cleanable and reusable air filters rather than reinforcing/introducing pre-filtration stages, relying on 100% re-circulating air as the only means of extending the filter lifetime, cleaning a disposal air filter and insisting on re-installing it after damaging its outer and internal structure. All these practices are not compatible with our twenty first century endeavors to enhance IAQ; these practices were used at times where our knowledge of air filtration was rather limited. Today, we realise that the air filtration process is dynamic and complex and is influenced by several parameters most of which are time-dependent such as dust/contaminant loading and pressure drop. To make a difference in the air filtration field, we need to confront the truth: existing testing methodologies require upgrading, testing apparatus require greater precision and testing standards need to be more comprehensive to include the parameters we never even considered. We cannot overlook what we know today about air filtration which would certainly augment the way we design, optimise and utilise air filters to better serve humanity.

The writer is Regional Director, Middle East, and International Consultant, EMW Filtertechnik, Germany. He can be contacted at iyad. al-attar@emw.de

References:

1 Gentry, W.G. “Aspects of health-related aerosol” in “Aerosols Handbook: Measurement, Dosimetry and Health Effects” (2005), Edited by Ruzer, L.S and Harley, N. H.. CRC Press.

2 Hinds, W.C. “Aerosol properties” in “Aerosols Handbook: Measurement, Dosimetry and Health Effects” (2005), Edited by Ruzer, L.S and Harley, N. H.. CRC Press.

Copyright © 2006-2025 - CPI Industry. All rights reserved.