Making a case for low voltage motors and equipment over their medium voltage counterparts for District Cooling applications, Nael Al Quqa enumerates their many advantages.

Making a case for low voltage motors and equipment over their medium voltage counterparts for District Cooling applications, Nael Al Quqa enumerates their many advantages.

In traditional power systems, medium voltage motors (MV motors) are usually used for pumps rated above 150kW. This preference of MV motors over low voltage motors (LV motors) is due to the high starting current of LV motors, which abnormally depresses the system voltage.

However, thanks to the advancement in technology of devices of starters (variable speed drives and reduced voltage soft starters), LV motors can now be used for pumps of sizes up to 600 kW and more, without any impact on the motors or the reliability of the overall system.

In the District Cooling industry, low voltage (LV) supply is used for all process pumps where motor sizes typically range from 75 kW up to 600 kW or more, based on project requirements. There are more than four million tonnes of District Cooling plants operating with LV motors in prestigious and critical projects across the GCC, such as airports, hospitals, financial centres, hotels, shopping malls, universities, residential centres and other essential projects without any failures or operational problems.

This paper illustrates the advantages of utilising LV equipment in District Cooling plants in terms of reliability, serviceability, operating costs, equipment size, spare parts and replacement costs, availability and delivery periods.

Reliability

Lack of information from manufacturers about the reliability of the power system equipment makes it difficult for buyers to decide whether an equipment of a power system is reliable or not. Though manufacturers do have the necessary information on warranty returns, this is usually not published.

Fortunately, however, industry groups and organisations have compiled reliability databases. One of the most extensive industrial databases is the Institute of Electrical and Electronic Engineers (IEEE) Standard 493-1997, IEEE Recommended Practice for Design of Reliable Industrial and Commercial Power Systems (Gold Book).

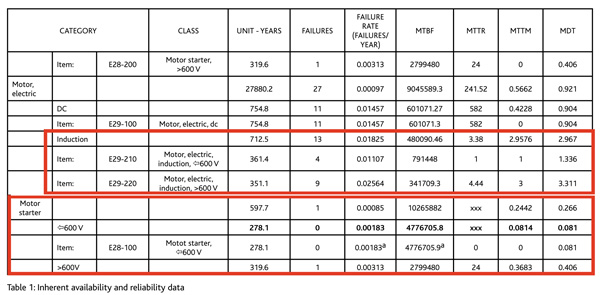

Below is a table extracted from IEEE Gold Book 2007 showing a reliability comparison of the two installations using LV and MV drives. The table shows the failure rates per year and also the downtime required for repair maintain and replace equipment. Motor and transformer failure data is quite extensive, and indicates that MV motors have more than double the failure rate of LV motors with higher downtime periods required for repair and maintenance of equipment. (Table 1, below)

Motor and equipment size

The physical size and weight of the MV motor is almost 25-50% more than the size of the LV motor. Moreover, the size of the MV electrical equipment is almost double the size of the LV equipment, especially the AC drives. Consequently, MV equipment is more difficult to handle or replace in case of failure during operation due to its heavier weight and larger physical dimensions.

Spare parts

LV motor and electrical equipment spare parts are cheaper and widely available, even locally, from various manufacturers. Most of the manufacturers/suppliers have a stock of LV products and spare parts that can be ordered without delay.

On the other hand, only a few manufacturers have MV motors and electrical equipment ranges. The spare parts need to be specially ordered from the manufacturer, as they are typically not available in stock, leading to higher replacement costs and longer delivery periods.

Service/repair/replacement

MV motors, AC drives, and electrical equipment require MV professional and trained engineers to handle and maintain. MV AC drives are almost always installed, started up, repaired and maintained by the manufacturer’s specialised field service engineers, which leads to higher service/repair costs. On the other hand, LV motors, AC drives and electrical equipment are easier to maintain by plant operators/technicians.

Moreover, MV motors have much higher replacement costs than LV motors and, therefore, will lead to higher operating and replacement costs during the lifetime of a District Cooling plant. Also, MV equipment will require longer delivery periods, consequently leading to longer downtime in case of replacement during the operating stage.

Motor-rated current

LV motors normally have a higher rated current compared to MV motors due to lower voltage level. This, however, has no impact on the life of the motor or operation, as motors are designed and rated to operate with higher current ratings.

In District Cooling plants, motors are aided by a VFD or a soft starter, which starts the motor smoothly by controlling the frequency or voltage. The starting current is:

The cost factor

For ratings of motors less than 600kW, the cost of the LV equipment is much lower than the cost of the MV equipment, especially for the variable frequency drives (VFDs). However, it needs to be noted that this is not the case for motor ratings above 600kW, as the cost of MV equipment is lower than the LV equipment due to the high cost of LV cables and drives.

Although motors above 600kW require a large number of LV transformers, these transformers will occupy more space in the plant and will increase the civil cost.

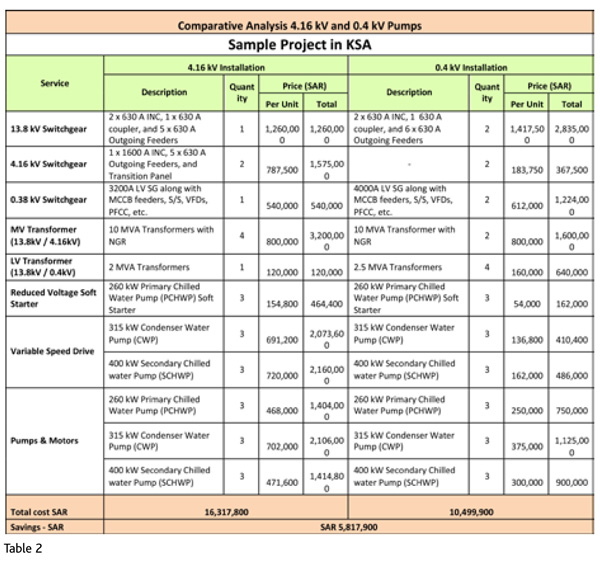

The table, above, shows the cost comparison between MV and LV motors for one of the District Cooling projects in the Kingdom of Saudi Arabia, where the design was changed from MV to LV motors. The utilised motor rating in this project is 260, 315, and 400kW. The total saving from converting the MV motors to LV motors is about 35% of the total electrical cost.

Conclusion

Reliability of LV motors is higher than that of MV motors.

LV equipment is lighter in weight with smaller dimension than MV equipment.

LV equipment is easier to handle in case of servicing or replacement than MV equipment.

The replacement cost and delivery periods in the LV system is lower than the MV equipment.

LV equipment spare parts are widely available at low cost, while spare parts for MV systems are less easy to obtain, have a longer delivery period and cost more.

LV equipment requires a lower capital, O&M and lower replacement costs than MV equipment.

LV motors are recommended for motor ratings up to 600kW. Above that rating, MV motors are preferred, since the cost of the LV equipment is much higher than MV equipment.

The writer is a LEED AP working as a Senior Electrical Engineer in DC Pro Engineering, specialising in District Cooling plants. He has designed electrical systems for more than 800,000 TR of District Cooling plants, and has eight years of experience in the field of construction, commissioning and consultancy. He can be contacted at: nkhamis@dcproeng.com.

References

Copyright © 2006-2025 - CPI Industry. All rights reserved.