As the person who played a crucial role in the OMD building at Dubai Media City being awarded the LEED Silver certification, Sougata Nandi of TECOM shares his experience of the process. En route, he demonstrates that the certification is an achievable goal.

As the person who played a crucial role in the OMD building at Dubai Media City being awarded the LEED Silver certification, Sougata Nandi of TECOM shares his experience of the process. En route, he demonstrates that the certification is an achievable goal.

By the time we started the LEED certification programme for the OMD building at Dubai Media City, we had already delivered two LEED-certified projects at TECOM, and the LEED Gold Metito HQ complex (in 2007). We had, therefore, grown in confidence and, perhaps prematurely, thought that we should be able to deliver LEED Gold projects incessantly. But surprises were in store, and at the end of the LEED certification of the OMD project, for the first time in my career, I was able to empathise with Sir Isaac Newton’s humility, when he stated, “I do not know what I may appear to the world, but to myself, I seem to have been only like a boy playing on the seashore, and diverting myself in now and then, finding a smoother pebble or a prettier shell than ordinary, whilst the great ocean of truth lay all undiscovered before me.”

By the time we started the LEED certification programme for the OMD building at Dubai Media City, we had already delivered two LEED-certified projects at TECOM, and the LEED Gold Metito HQ complex (in 2007). We had, therefore, grown in confidence and, perhaps prematurely, thought that we should be able to deliver LEED Gold projects incessantly. But surprises were in store, and at the end of the LEED certification of the OMD project, for the first time in my career, I was able to empathise with Sir Isaac Newton’s humility, when he stated, “I do not know what I may appear to the world, but to myself, I seem to have been only like a boy playing on the seashore, and diverting myself in now and then, finding a smoother pebble or a prettier shell than ordinary, whilst the great ocean of truth lay all undiscovered before me.”

DUBAI MEDIA CITY – A THRIVING HUB

In order to contextualise its LEED-certification process, it would not be inappropriate here to describe in brief, the backdrop against which the OMD Building project was undertaken. TECOM Investments launched Dubai Media City (DMC) – its second brand – in 2000, to support and develop a cluster for the media industry.

Ideally located on Sheikh Zayed Road, both from the commercial as well as sustainability points of view, it is not close to any water body and is accessible through RTA bus lines. It complies with development density guidelines, has all support services required for commercial offices within the zone, and several other green building features.

As originally envisaged, the cluster has grown tremendously as a thriving media hub. Many global media giants and promising entrepreneurial ventures have joined DMC’s vibrant community. The City provides advanced infrastructure for media-related businesses to operate globally. DMC is the place where activities, such as media consultancy, publishing, music, film, new media, leisure and entertainment, broadcasting, media and marketing services, and business and news agencies flourish. Companies based in DMC include CNN, Leo Burnett, Thomson Reuters, AFP, The Neilson Company and Dow Jones International Limited.

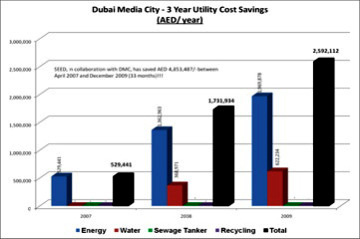

Figure 1: A three-year utility cost savings at Dubai Media City

Since April 2007, TECOM Investments, through its Sustainable Energy & Environment Division (SEED) has also implemented an Energy and Water Conservation Programme at DMC, in line with the Sustainable Development Policy of TECOM Investments. This conservation programme has achieved significant results for DMC, as summarised in Figure 1.

On a cumulative basis, the Energy and Water Conservation Programme at DMC has generated a net utility cost savings of Dh4.85 million during a period of 33 months – from April 2007 to December 2010. Of these savings, Dh3.86 million was achieved from electricity savings, which was a result of good housekeeping practices for MEP equipment. The remaining Dh0.99 million was saved in water costs. The overall conservation programme required an investment of Dh118,000 (approximately), which has paid back in 70 days, at the present rate of annual savings.

These initiatives are not only in line with the energy and water-saving goals laid out in the sustainable development policy of TECOM Investments but also support the LEED certification of the existing buildings at DMC.

DMC, in collaboration with SEED, has also been pro-active in engaging several tenants in the ongoing energy conservation programme, whereby the tenants are guided on no-cost conservation measures and good housekeeping practices.

It is, thus, evident that DMC already had a favourable ethos when the OMD Building project was initiated – an existing free zone in a well-established, pro-sustainable site with most of its buildings developed.

LEED FEATRURES OF THE OMD BUILDING

The project:

The OMD building was designed to be a commercial building intended to be occupied by OMD as a single long-term tenant. With a built-up area of 55,715 square feet, the building will house offices, meeting rooms, restaurant, basement and surface parking. The ground floor will be occupied by a food outlet, and the offices will be located on the remaining floors.

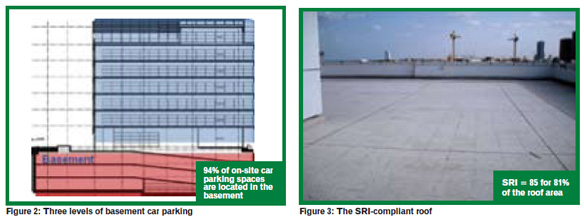

The chillers, chilled water pumps and FAHUs are located on the roof. Most of the car parking area is underground, and is in the form of three levels of basements. Although the building has only 55,715 square feet of built-up area, it has three basements, ground and six floors. As it happened, this turned out to be a crucial factor during the LEED certification process.

Site sustainability:

Site sustainability plays an important role, as it is through this section of the LEED rating system that a building becomes part of a community, and holistic sustainable development is achieved. Given the location of the project within the precincts of DMC, it was able to perform quite well in this segment, securing nine points of the possible 15.

The site had other additional advantages:

The ‘Average Neighbourhood Development Density’ worked out to approximately 104,000 square feet/acre, given that the project was constructed on the only empty plot available in the middle of several buildings. The ‘Project Development Density’ worked out to 256,000 square feet/acre. The building footprint being small on both the project as well as the neighbourhood levels, the project was in compliance with the LEED requirements. The project, thus, exploited the advantages of being located in a previously developed community.

Again, for the same reasons, the project has the advantage of being accessible via two RTA bus lines, as part of alternative transportation credit requirements.

Given the fact that a significantly large multi-storey car park building already exists right in front of the project, we were able to limit the number of car parking slots to only the minimum required by zoning guidelines. This is a further demonstration of the advantages a green building can enjoy, if constructed in a previously developed urban setting with readily available infrastructure.

As part of the LEED requirements, and also in the TECOM spirit of transforming the built environment towards becoming more sustainable, SEED prepares a ‘Tenant Design and Construction Guideline’ for every project undergoing a LEED certification. This guideline is now for use by OMD, the intended tenant for this project.

Being located in an urban setup, we were definitely mindful of the heat island effect that buildings typically create. Therefore, both credits on heat island – non-roof and roof – were aggressively pursued and successfully achieved. Except for the mechanical equipment area, the entire roof surface is covered with SRI-compliant white terrazzo tiles to reduce solar heat gain.

Water efficiency:

The intention of this credit is to “maximise water efficiency within tenant spaces to reduce the burden on municipal water supply and wastewater systems”. (Source: USGBC). SEED’s Water Conservation Programme at Site A (DIC, DMC & DKV) has secured the 2009 Emirates Energy Award. Being a project located at DMC, water conservation, therefore, was a prime objective on this project, too, and it performed extremely well on this count, securing four points out of the available five in the Water Efficiency category. An additional innovation point was also secured due to exemplary performance in water use reduction.

The project did not pursue the ‘Innovative Wastewater Technologies’, as it is located in an urban setting with connection to the Dubai Municipality’s sewerage network. Onsite sewage treatment was, therefore, consciously avoided.

Here, it must be stated that the project’s water savings performance has been benchmarked against both US EPA standards as well as local practices (See Figure 4).

Here, it must be stated that the project’s water savings performance has been benchmarked against both US EPA standards as well as local practices (See Figure 4).

In addition, the following water-saving measures have been adopted:

While LEED requires that the water savings are calculated against US EPA standards, we also do a consumption comparison against ‘standard’ consumptions in TECOM buildings (flow rates in water fixtures prior to implementation of the Water Conservation Programme), in order to put the extent of savings into perspective. Therefore, while the project achieved water saving of 50.5% against US EPA standards, when compared to a standard building, the project is 61.5% more water efficient.

Water-efficient landscaping:

The project has achieved a 100% savings in potable water requirement for landscaping through a two-pronged approach. The irrigation water requirement has been minimised by utilising native plants with low water consuming properties. For the first time in a TECOM project, the AC condensate from the building’s HVAC system has been connected to the irrigation tank located in the basement (See figures 5a and 5b).

The project has achieved a 100% savings in potable water requirement for landscaping through a two-pronged approach. The irrigation water requirement has been minimised by utilising native plants with low water consuming properties. For the first time in a TECOM project, the AC condensate from the building’s HVAC system has been connected to the irrigation tank located in the basement (See figures 5a and 5b).

Energy efficiency:

The intention of this credit is to achieve increasing levels of energy conservation beyond the referenced standard to reduce environmental impacts associated with excessive energy use (Source: USGBC). This was one of the two key elements of the LEED certification process that we were surprised with. Energy conservation being our primary thrust area, the most attention was paid to this segment of the LEED certification. Based on past experience of LEED certification projects, a standard set of energy conservation measures are always applied to all our projects. These include:

Improved insulation for walls and glass

Improved insulation for walls and glassAlthough these measures would typically allow the project to achieve an energy savings of around 20%, the project experienced a couple of constraints: 1) The architectural design of the project resulted in the building envelope having more than 60% glazed area. This is significantly higher than the 40% prescribed by ASHRAE 90.1-2004 for the base building, and 2) Since building is higher than five floors, ASHRAE 90.1-2004 requires the base building to be modelled using water cooled chillers, which have lower KW/TR compared to air-cooled chillers. However, for a project having a built-up area of only 55,000 square feet, the HVAC tonnage required is in the range of only 150 TR. Water-cooled chillers will rarely be used for such small capacities, and the project uses air-cooled chillers as standard practice.

Due to these two severe constraints to the base building energy use, the Visual DOE energy model identified an energy-saving potential of only 11%, which is equivalent to Dh50,090 of energy cost savings per year, in spite of the adoption of the energy conservation measures. This meant that the project was able to secure only one point in the ‘Optimise Energy Performance’ category, and also missed the Gold level of certification by two points.

Indoor Environmental Quality:

The intention of this credit is to “provide optimal indoor air quality to tenants” (Source: USGBC). This is another LEED segment where the project performed very well, scoring eight points out of a possible 11 points. The facility is designed to enjoy 30% more fresh air, compared to ANSI/ASHRAE 62.1-2004: Ventilation for Acceptable Indoor Air Quality standard requirements, making the building very healthy for its occupants. Also, the HVAC system design complies with ANSI/ ASHRAE 55-2004: Thermal Environmental Conditions for Human Occupancy standard, and thus, provides a comfortable thermal environment for the building occupants.

The intention of this credit is to “provide optimal indoor air quality to tenants” (Source: USGBC). This is another LEED segment where the project performed very well, scoring eight points out of a possible 11 points. The facility is designed to enjoy 30% more fresh air, compared to ANSI/ASHRAE 62.1-2004: Ventilation for Acceptable Indoor Air Quality standard requirements, making the building very healthy for its occupants. Also, the HVAC system design complies with ANSI/ ASHRAE 55-2004: Thermal Environmental Conditions for Human Occupancy standard, and thus, provides a comfortable thermal environment for the building occupants.

The project utilises operable windows in lieu of individual controls, in order to achieve the ‘Controllability of Systems’ credit. The windows of this building are positioned in such a way that 74% of the occupied area complies with the requirement of being within 20 feet from the external wall and within 10 feet from either side of the window. Of course, thanks to the high percentage of glazing and the shallow nature of the building, the project easily complied with the requirements of ‘Daylight and Views’.

PROJECT PERFORMANCE

This project secured 32 points to qualify for the LEED Silver certification level. The project was able to secure all 32 points that it applied for.

KEY PROJECT FINANCIALS

At this juncture, it is important to share the financial cost-benefit of LEED projects, in order to dispel the popular myth about green buildings costing more. In fact, after the energy- modelling challenges, this was the second key lesson learnt from this project – if an organisation can make green design mainstream, then the concept of green premium does not arise, subject to the level of certification desired. It is interesting to note that, on this project, it was a struggle to identify the additional cost for going green. In fact, other than the administrative costs for the certification and fees paid for the energy modelling, the project did not incur any additional financial burden to achieve the LEED certification.

At this juncture, it is important to share the financial cost-benefit of LEED projects, in order to dispel the popular myth about green buildings costing more. In fact, after the energy- modelling challenges, this was the second key lesson learnt from this project – if an organisation can make green design mainstream, then the concept of green premium does not arise, subject to the level of certification desired. It is interesting to note that, on this project, it was a struggle to identify the additional cost for going green. In fact, other than the administrative costs for the certification and fees paid for the energy modelling, the project did not incur any additional financial burden to achieve the LEED certification.

In effect, the project has incurred a ‘Green Premium’ of only 0.11%. Figures 11 and 12 further demonstrate the point.

LESSONS LEARNT

Although a small project in terms of its size, it taught us two very unique lessons:

1. The energy-modelling exercise can be very tricky. Although the ASHRAE 90.1-2004 energy-modelling guidelines require the use of water-cooled chillers for a building that is higher than five floors, if the building’s HVAC tonnage requirement is small, it will almost invariably be designed with air-cooled chillers. The project will then significantly lose points on this count.

2. If green becomes mainstream, no additional costs need to be incurred for a project to secure a LEED certification, unless the project aims to secure a very high rating level.

EPILOGUE

EPILOGUE

At the time of writing this article, we have delivered two more LEED certified buildings, bringing TECOM’s tally to five LEED certified projects in 10 months – between April 2009 and January 2010. This achievement consolidates TECOM’s leadership position in sustainable development further, considering that there are only eight other LEED-certified projects in the entire GCC, as of January 2010 tally (see figure 13).

The growing number of certified green projects clearly removes any ambiguity about whether or not external rating systems work in this region. Of the 13 certified projects in the GCC, three are LEED Platinum, six LEED Gold, three LEED Silver and one LEED certified. A majority of the projects being LEED Gold or above, clearly demonstrates that LEED not only works in this region, but actually works quite well. TECOM Investments, through (SEED), is committed to creating a sustainable development industry in the region. As an offshoot of this, the dissemination of technical and financial information from its projects is helping create local case studies – so vitally important for green building practitioners.

The growing number of certified green projects clearly removes any ambiguity about whether or not external rating systems work in this region. Of the 13 certified projects in the GCC, three are LEED Platinum, six LEED Gold, three LEED Silver and one LEED certified. A majority of the projects being LEED Gold or above, clearly demonstrates that LEED not only works in this region, but actually works quite well. TECOM Investments, through (SEED), is committed to creating a sustainable development industry in the region. As an offshoot of this, the dissemination of technical and financial information from its projects is helping create local case studies – so vitally important for green building practitioners.

Ref 1: Memoirs of the Life, Writings, and Discoveries of Sir Isaac Newton (1855) by Sir David Brewster (Volume II. Ch. 27)

Sougata Nandi, B Tech, M Tech, LEED AP, PMP, is the Director, Sustainable Energy & Environment Division (SEED), TECOM. He can be contacted at: Sougata.nandi@tecom.ae/ Sougatan@eim.ae

Copyright © 2006-2025 - CPI Industry. All rights reserved.