Highlighting that thermal insulation and pre-insulated panels can negatively impact climate change if they are not manufactured in a responsible manner, as enshrined in international agreements, Sarmad Fakhri asserts that foam insulation products need to be not only CFC-free but also HCFC-free to ensure low global warming potential and zero ozone-depleting potential.

Our way of life threatens the very planet that we live on, and for our future to be environmentally sustainable, we need to act – and now!

The seeds sown at the Vienna Convention in 1985 to halt and reverse the depletion of the ozone layer are slowly coming to fruition in the GCC region. The Convention, which took place over 30 years ago, enabled unprecedented international cooperation in researching the effects of ozone-depleting substances (ODSs) on the ozone layer, and was the basis on which the Montreal Protocol was produced in September 1987. At the time, 24 countries and the European Economic Community signed the Protocol, which requires the reduction and eventual phasing out of CFCs and other ODSs. It has since been amended five times, most recently in Montreal in 2007, each time calling for more stringent targets.

Sarmad Fakhri

Article 5 Parties and their commitment

In 1989, Article 5 of the Montreal Protocol was developed. This allowed developing countries to become part of the action against climate change. Recognising the need to balance environmental concerns with the demands of the industry, the Article 5 Countries that signed the Protocol committed themselves to the phasing out of Halons, CFCs and Carbon Tetrachloride by 2010. The United Arab Emirates, Qatar and Oman, too, signed the Protocol and came under the ambit of Article 5 Countries and, therefore, committed to phase-out these ODSs.

Implications of GWP and ODP

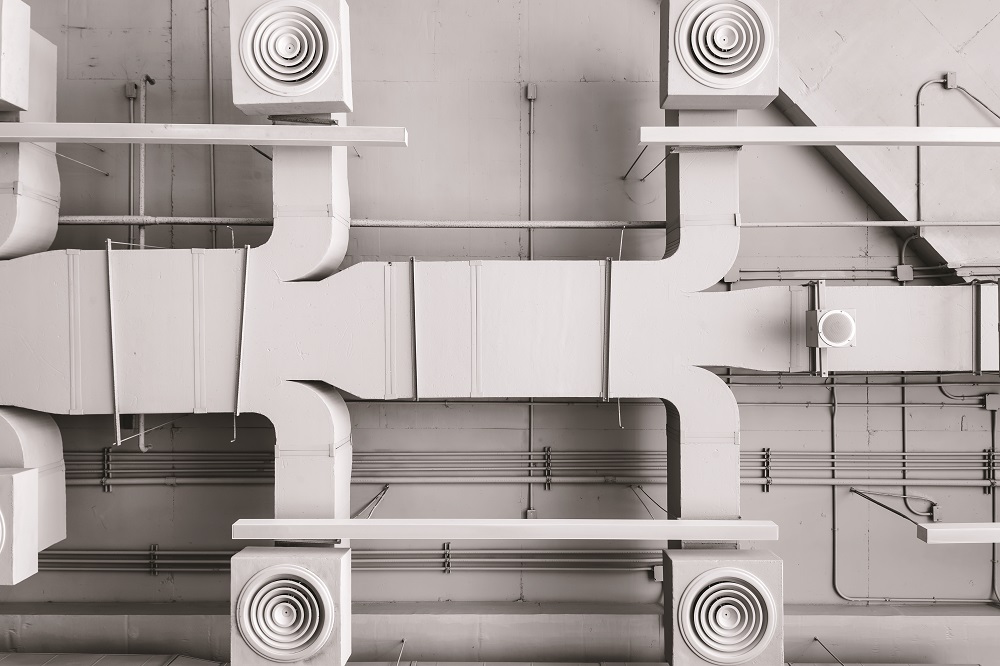

CFCs, HFCs and HCFCs are commonly used in refrigeration and air conditioning facilities. However, HCFCs (and previously CFCs), can also be used as blowing agents during the manufacturing of foam insulation products. Blowing agents used in foam insulation production will have a different global warming potential (GWP) and ozone depletion potential (ODP).

Under Estidama’s Stewarding Materials section, one credit point is available, providing all thermal insulation used has an ODP of zero and a GWP of less than five

In this context, it is important to understand that, whilst reducing energy consumption and carbon emissions of a building, thermal insulation and pre-insulated panels can impact climate change if they are not manufactured in a responsible manner. To underscore the point, blowing agents, such as HCFCs, used in the manufacture of foam insulation products, can be released into the atmosphere, and certain blowing agents that manufacturers are using can accelerate climate change.

HCFCs, whilst significantly lower than CFCs, can have a relatively high ODP.¹ ODP is the ratio of relative amount of degradation to the ozone layer caused by a substance. The ODP of HCFCs is thought to be between 0.001 and 0.11, while other substances, such as Pentane, have zero ODP, but also offer a low GWP.

GWP is a relative measure of how much heat a greenhouse gas traps in the atmosphere. The more heat the gas traps, the bigger the potential for global warming. For example, HCFCs have a GWP of up to 2,000 times that of carbon dioxide, and so, these substances are considered to have GWP. Further information is provided by the European Parliament, which lists the GWP of each blowing agent that can be used during the manufacture of foam insulation materials.²

Thermal insulation panel

After the phase-out of CFCs, many foam insulation manufacturers turned to HCFCs as an alternative, as they have a much lower ODP than CFCs. However, following the 2007 amendment, the phase-out of these interim chemicals, should really have already begun within Dubai, as per Dubai Municipality’s guidance document which enforces the phase-out.³

Additionally, Estidama rating systems in Abu Dhabi provide guidance.4 Under the Stewarding Materials section, one credit point is available, providing all thermal insulation used has an ODP of zero and a GWP of less than five.

However, despite this guidance, manufacturers are continuing to use HCFCs as blowing agents for foam insulation. So, are HCFCs safe for the environment? From research, the short answer is, no.

As such, specifiers in the United Arab Emirates, Oman and Qatar and, in fact, all countries across the GCC region, need to be aware that specifying all types of foam insulation products need to be not only CFC-free but also HCFC-free to ensure low GWP and zero ODP insulants.

Moving forward

Ideally, pre-insulated ductwork systems with ODP of zero and a low GWP would be an easy route for specifiers, engineers and contractors to help combat climate change.

References:

Sarmad Fakhri is Managing Director, Kingspan Insulation. He can be contacted at info@kingspaninsulation.ae

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Copyright © 2006-2025 - CPI Industry. All rights reserved.