Faulty installation of insulation material in air conditioning applications is not an uncommon occurrence. Laurențiu Pestrițu highlights typical mistakes technicians make and provides a few handy tips

Faulty installation of insulation material in air conditioning applications is not an uncommon occurrence. Laurențiu Pestrițu highlights typical mistakes technicians make and provides a few handy tips.

INTRODUCTION

Insulation materials inherently possess high flexibility and adhesive property. This is due to the fact that synthetic rubber is particularly user-friendly. The elastomeric insulation materials are not only easy to install, but they have very good technical properties to ensure the long-term functionality of the insulation system. Nevertheless, there is no ‘100% built-in security’ even when a high-quality insulation material is installed incorrectly. Considerable effort is needed to repair the system if it sustains any damage, as it can prove to be very serious, in case of low-temperature applications.

Proper installation work is, therefore, absolutely necessary, especially when insulating complex pipe systems. It needs to be remembered that insulation work must be carried out meticulously so that there are no weak points. This is all the more important, because mistakes can occur under challenging conditions at the building site. In this context, the adage, “A chain is only as strong as its weakest link,” provides an apt analogy and also sounds a warning.

WAYS TO AVOID COMMON MISTAKES

Faulty installation work can be easily avoided if insulation contractors follow a few simple rules. Condensation control and minimising heat loss are the two important factors that need to be kept in mind during cold applications. An insulation system has to be protected against moisture penetration, must be thermal efficient, fire resistant and easy to install. The following are the main technical criteria required:

Insulation work needs to be treated seriously, especially when it comes to refrigeration and air conditioning applications.

Careful planning of a low-temperature insulation project involves three important aspects:

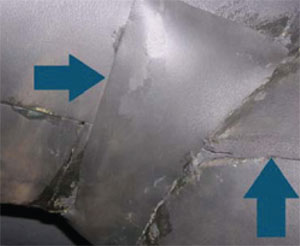

Mistakes in the installation of elastomeric insulation materials usually arise when measuring fittings, cutting the material to size and gluing the parts. However, errors can also be made when using mounting devices or functional substructures and creating correctly glued joints with ‘alien’ materials, for example, in the vicinity of pipe brackets. Incorrect installation could prove expensive, especially in sensitive areas of pipe brackets.

Figure 1: An illustration of problems waiting to happen: the insulation material has not been joined to the ‘alien’ refrigeration pipe clamps correctly

Taking accurate measurements:

The first mistake is often made at the very outset, when taking the measurements. A word of advice, therefore, is that when elastomeric insulation tubes are installed, material for the fitting piece should not be cut to the exact length of the pipe to be insulated, but should be one to two centimetres longer. Only then is it possible to ensure that the material is installed ‘under compression’. In this case, the compressive forces that occur on the seam provide mechanical support for the chemical bonding process of the adhesion (cold vulcanisation).

Initial preparation:

Preparatory work plays as important a role as actual installation, and, therefore, demands careful attention. It needs to be kept in mind that functional insulation can be guaranteed only when the initial steps have been carried out properly.

Often, insulation substructures and reinforcements are necessary around fittings, when complex objects are insulated. When reinforcing the substrate on a flange valve, for example, a rounded sheet of metal which has been cut to fit should be bedded on the flange. This is crucial for both visual appeal and efficiency, as it allows a stricter geometric shape of the valve cap and also increases reliability. This way, the insulator is safe when cap seam is closed, as only the reinforced substrate allows him to exert the pressure needed to close the seam. This is because only the reinforced substrate allows him to exert the pressure needed to close the seam securely.

A common erroneous practice can be observed when valve caps are fabricated from elastomeric sheet material. Usually, those who fabricate metal claddings make the mistake of determining the length of the valve body cover by rolling the material end disc over the material to be used. However, in this way, it is only possible to determine the inner circumference as the procedure does not take the insulation thickness into account.

In order to measure the precise length of the valve body cover, it is necessary to know how long the outer surface of the insulation is. The easiest and the correct way to do this is to lay a strip of material in the same insulation thickness in a relaxed state around the end disc. To avoid overstretching, the strip should be at least 50 mm wide. Figure 2 shows an almost unbelievable patchwork. It also demonstrates the importance of fundamental knowledge of true-to-size execution.

Figure 2: The example demonstrates how the insulation material should not be installed

RESPECTING THE LAWS OF PHYSICS

By acquiring and extending their theoretical knowledge of the laws of Physics through regular training, installers can also detect incorrect installation work based on their ‘gut feeling’. Let’s take a simple example. When installing insulation material on refrigeration pipes, it should always be ensured that the convective heat transfer is not restricted, as convection has a substantial influence on the level of heat transfer coefficient.

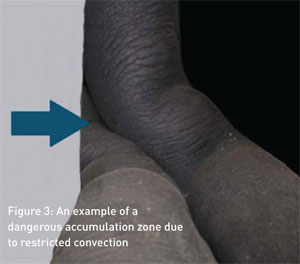

If pipes and ducts are too close together or if there is too little clearance between walls and other fixtures, then accumulation zones which prevent air circulation needed for a sufficiently high surface temperature can occur. This means that a lower heat transfer coefficient occurs because the convective part decreases and, as a result, the risk of condensation formation increases considerably.

If pipes and ducts are too close together or if there is too little clearance between walls and other fixtures, then accumulation zones which prevent air circulation needed for a sufficiently high surface temperature can occur. This means that a lower heat transfer coefficient occurs because the convective part decreases and, as a result, the risk of condensation formation increases considerably.

When carrying out low-temperature insulation work, it is crucial to ensure that there is sufficient clearance between insulated pipes and between the pipes and the wall or ceiling. To avoid restricting convective heat transfer, at least 100 mm clearance (even 1,000 mm for vessels, fittings, etc.) is required. In case of pipes which are not laid in accordance with these guidelines, the technician should report the matter in advance, instead of blindly accepting the situation and carrying out the insulation work required.

TIPS FOR CORRECT ADHESION

Correct method of gluing plays an important role in the functionality of low-temperature insulations. Here are a few tips about how to install and glue multi-layered insulation of the same type or of different types of systems. For example, it may be necessary to encapsulate an elastomeric insulation system using mineral-fibre shells for fire safety reasons. Consequently, the dew point is shifted into the open-cell mineral-fibre system. Keeping this in mind, the insulation thickness should be recalculated (multi-layer calculation) in order to prevent this from happening. Increasing insulation thickness of the closed-cell material ensures that the dew point lies inside the closed-cell insulation material.

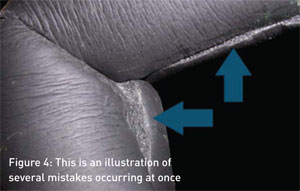

In Part II, we will focus on the serious consequences of approaches such as the one shown in Figure 4, and will give important tips on the necessary preparatory work and on professional gluing techniques.

In Part II, we will focus on the serious consequences of approaches such as the one shown in Figure 4, and will give important tips on the necessary preparatory work and on professional gluing techniques.

The writer is Insulation Product Manager (Middle East, India & Africa) at Hira Industries. He can be contacted at laurentiu@rhira.com.

References:

Copyright © 2006-2025 - CPI Industry. All rights reserved.