Independent testing can be a catalyst for a healthy dialogue and a process for continuous improvement, argues Jeremy McDonald

Since the early days of the pandemic, there has been increasing awareness that Indoor Air Quality (IAQ) is a key factor in the mitigation of the spread of COVID-19 viral particles. Business managers from a wide spectrum of businesses – nursing homes, K-12 and office complexes, to name a few – have been inundated with various solutions, all with the promise of protecting building visitors and staff.

With all this information, facility managers are, at times, overwhelmed wondering which product is the best for their particular needs.

This article will explore and define a pragmatic approach to testing and verifying the performance of IAQ investments. While the real-world experiences at an upstate NY School District – New Rochelle School District – focuses on testing and verification of bi-polar ionisation (BPI), the independent testing approach I describe in this article can be applied to a host of technologies.

BACKGROUND

One morning in early April 2020, in the early days of this long pandemic, I was sitting with two colleagues – we will call them Marty and Bill, because those are, indeed, their names – trying to wrap our heads around how the deadly viral particle, SARS-CoV-2 spreads. Through our deliberations, which were based on close to 100 years of HVAC experience, we kept coming back to the same conclusion – that this very tiny, invisible viral particle, which is more than 100 times less than the diameter of fine beach sand1, would be at its most dangerous in spaces with high occupant density, lack of ventilation and sub-par relative humidity.

Over the next few months, we explored a host of IAQ strategies. Although we had experience with several of these technologies, they were historically viewed as “nice to have” air-cleaning technologies, rather than a primary defence of protecting building occupants. As we brought ourselves up to speed on the nuances of the most marketed technologies, such as photocatalytic oxidation (PCO), BPI and ultraviolet (UV-C), we came to the conclusion that testing and verification of results offered the key to determine what works, and what is

ineffective.

After some brainstorming, we came to the conclusion that to analyse the real-world application of these “old but new” air-cleaning technologies, we need to apply the same independent commissioning process, which is commonly applied to any major mechanical/electrical project. Be it a new air-handling system, BMS, chiller plant or what have you, the independent commissioning process is always the same: The Cx Agent will review the design criteria and specifications, develop a test and then independently test the system to determine if the new mechanical/electrical system performs to the desired outcome.

The balance of this paper will lay out a real-world example of the New Rochelle School District, a community just north of New York City, which experienced firsthand the trauma of the early days of the pandemic and how data-driven commissioning can show real-world performance of air-cleaning strategies.

PROOF OF CONCEPT

The community of New Rochelle was front and centre in the early days of the pandemic, when one of its community members, dubbed Patient Zero by the press2 , fell ill with COVID-19. The story of Patient Zero was the precursor to the viral spread, shutdowns, and the social and economic dislocation that we all experienced, here in the United States and throughout the world.

As “normalcy” began to return in the spring of 2021, the New Rochelle School District decided to embark on a case study to explore the IAQ benefits of BPI. Working with Pandemic Solutions, which is based in New Rochelle, and Atmos Air, a vendor for BPI, they came to the conclusion that before they invested in BPI for the whole district, testing the systems in a few places was more prudent.

New Rochelle reached out to Guth DeConzo Consulting Engineers to perform the testing and validation. After discussions and deliberations, my team and I set the following parameters for the test:

THE PILOT TEST

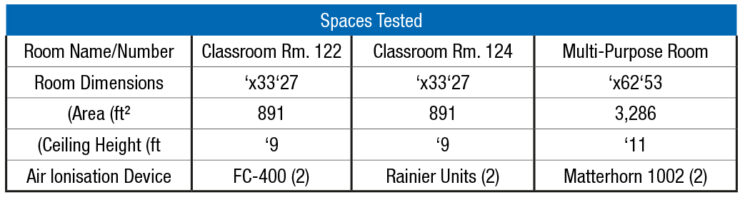

The pilot test was done for a diverse set of K-12 spaces. Recognising that the intent was to determine if the ionisation could be successful under different operating conditions, two class rooms and a multipurpose room were chosen. One classroom was conditioned with a traditional unit vent, while the other classroom didn’t have mechanical ventilation. The multipurpose room was served by an air-handling unit.

The basic information for the three locations are shown below.

Figure 1: Test Basic Information-Pilot Study

Once the criteria were established, Guth DeConzo developed a testing procedure as follows:

Once the criteria were established, Guth DeConzo developed a testing procedure as follows:

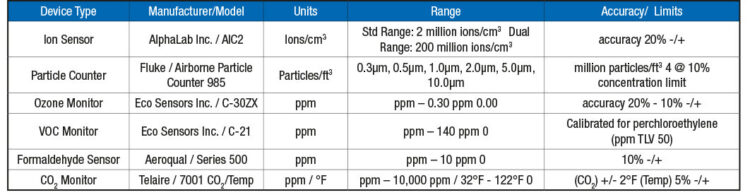

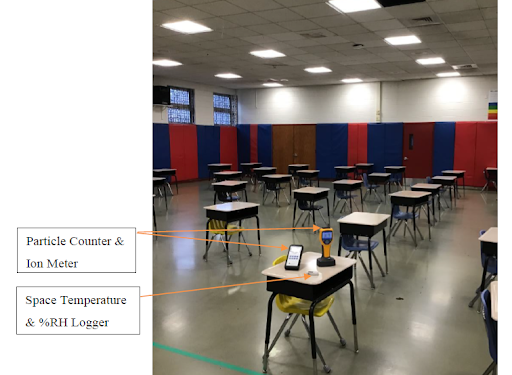

Setup testing equipment in centre of room at desk level. Refer to Figure 1.

Figure 2: Testing Equipment

THE PILOT TEST RESULTS

THE PILOT TEST RESULTS

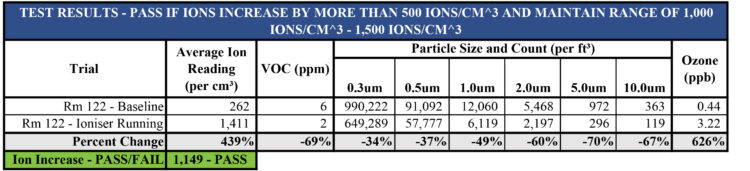

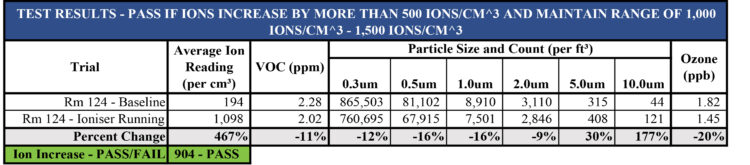

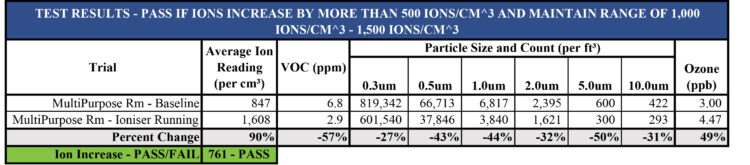

The test results for the three spaces are shown below…

Figure 3: Test Results – Pilot Study

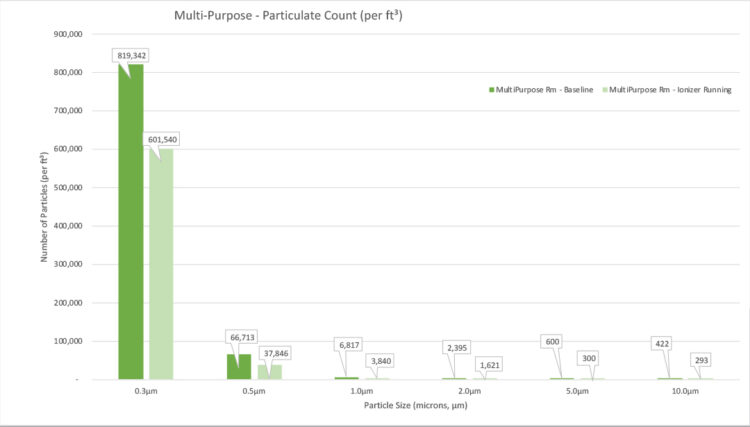

The above chart (Figure 3) is a graphical interpretation of the particulate data. Presenting this data this way is important to educate the client and stakeholders on what is happening (that is, particle counts are being reduced) through the invisible process of air ionisation.

Figure 4: Site testing equipment and space

Figure 5: Particle Count Reduction (for multiple size particles)

A review of the data revealed the following:

After conferring with the client and reviewing the results, it was agreed that the testing was satisfactory; and the client elected to install the air ionisation technology throughout the District.

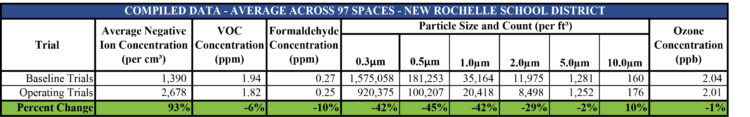

Once the air ionisation installation was completed for the District, Guth DeConzo was retained to perform testing for approximately 10% of all installations, which was approximately 100 spaces in total.

Also, recognising the public’s concern regarding “unintended consequences” of IAQ air cleaning, we added formaldehyde concentration, which is part of the Aldehyde family and is of special concern to public health officials, to the complement of contaminants my team and I were testing for.

At the completion of the study, a formal report was completed and provided to the owner. The study included the methodology, test results (by space for each of the approximately 100 spaces selected), cut sheets of equipment and supporting research articles on air ionisation.

The summary results of the complete testing are shown in the table, below:

Figure 6: Summary of Results – District-wide Test (District-wide average)

CONTINUOUS COMMISSIONING – BUILDING TRACING

The New Rochelle management emphasised investment in IAQ is not a one-shot deal but more of a new way of thinking of how we manage our buildings. With this in mind, New Rochelle tasked Guth DeConzo with the following additional tasks:

THOUGHTS ON FURTHER TESTING

Currently, there is no independent testing procedure for “in use” air-cleaning devices. If building IAQ tracing is to be successful, we need to have established rules, so we all know what success looks like.

Below is a proposal for IAQ testing protocol…

CONCLUSION – WHY INDEPENDENT TESTING

The pandemic served to surface the need for ensuring air quality in our facilities and buildings, and our hope is that third-party testing will lead us down a path for validating solutions that monitor for unknowns and invisible toxins that we were only made aware of as a result of the pandemic. The pandemic necessitated improvements in IAQ, but good IAQ also serves to maintain a healthy environment for non-public health emergency times, which we hope is the norm in the future.

More so, independent testing can be a catalyst for a healthy dialogue and a process for continuous improvement. As an example, only through healthy dialogue and challenge of results by the client, we concurred that we should add formaldehyde testing for future test results.

Only through independent testing, objective evaluation of the results and transparent reporting of results can we determine if the client’s investment in air cleaning devices are producing results. For decision-makers, who are concerned with results for their stakeholders, independent testing is a sure way to ensure the investment in air cleaning is worth it.

1Carmen Ang, https://www.weforum.org/agenda/2020/10/covid-19-coronavirus-disease-size-compairson-zika-health-air-pollution

2Maura Hauman and Scott Stump, May 11th 2020, Today, “New York’s coronavirus ‘patient zero’ tells his story for the first time: “Thankful that I’m alive”

3Dr Philip M. Tierno Jr, Professor of Microbiology and Pathology, New York University School of Medicine,

“Cleaning Indoor Air using Bi-Polar Ionization Technology”, April 2017

4https://www.epa.gov/indoor-air-quality-iaq/volatile-organic-compounds-impact-indoor-air-quality

Copyright © 2006-2025 - CPI Industry. All rights reserved.