Growing awareness about the importance of Indoor Air Quality has elicited an increased interest in air cleaning products in the HVAC industry. Though there is a wide array of appliances which employ sophisticated technologies, they also come with caveats and safety considerations that need to be addressed, says Chante’ White Maurio. She evaluates the options available.

Growing awareness about the importance of Indoor Air Quality has elicited an increased interest in air cleaning products in the HVAC industry. Though there is a wide array of appliances which employ sophisticated technologies, they also come with caveats and safety considerations that need to be addressed, says Chante’ White Maurio. She evaluates the options available.

In recent years, Indoor Air Quality has become increasingly important in residential, commercial and industrial environments due to allergies, respiratory concerns, pollution, and regulations. With greater focus on indoor air quality comes an increased demand for air cleaning products.

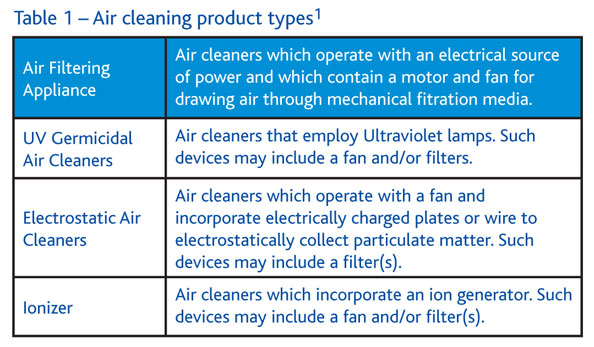

Electrical appliances that address indoor air quality can be loosely grouped into four primary categories: air filtering appliances, UV germicidal air cleaners, ionisers, and electrostatic air cleaners (definitions provided in Table 1). These products may be portable (provided with a cord and plug) or dedicated to one location by being wall-mounted, ceiling-mounted, duct connected or plenum connected.

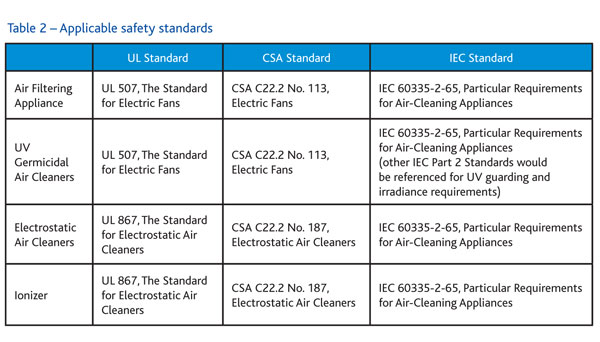

The category of air cleaning appliance determines the safety standard used for evaluating a product. Table 2 shows the US, Canadian and International electrical safety standards applicable to these appliances. In the US, media provided as a part of an air filtering appliance connected to or within the duct or plenum space are additionally required to comply with a fire safety standard, UL 900, “Air Filter Units.” In Canada the Standard is ULC S111, “Standard Method of Fire Tests for Air Filter Units.”

The category of air cleaning appliance determines the safety standard used for evaluating a product. Table 2 shows the US, Canadian and International electrical safety standards applicable to these appliances. In the US, media provided as a part of an air filtering appliance connected to or within the duct or plenum space are additionally required to comply with a fire safety standard, UL 900, “Air Filter Units.” In Canada the Standard is ULC S111, “Standard Method of Fire Tests for Air Filter Units.”

In addition to the Table 2 products/standards, and due to increasing demand, UL is currently developing a US standard for commercial and industrial indoor air quality systems of the ozone generating type. It will initially be published as an Outline of Investigation, UL 867A “Commercial/Industrial Indoor Air Quality Systems, Ozone Generating Type” until it has completed the consensus standards development process.

Technical considerations

Air cleaning technologies typically have, in addition to the usual fire, electrical shock and mechanical hazard considerations, unique technical considerations related to the technology employed in the design and the expected use. These include, but are not limited to, ozone generation, high voltage arcing, and UV radiation exposure. Each of these items is discussed below from a US market perspective.

Ozone

Ozone can be naturally produced by a variety of sources and often has a background presence in the air we breathe. In electrostatic air cleaners and ionisers, ozone is produced as an unintended by-product of the electrical discharges associated with the operation of the high voltage circuit used to help capture air particles. User exposure to ozone may affect the central nervous system, heart and vision. However, ozone predominantly affects the respiratory system. For this reason, the appliance safety standards include requirements to limit the ozone produced.

In the US, UL 867 limits the ozone produced by portable products to 0.05 ppm (50 ppb) measured near the appliance. The ozone produced by duct and plenum-mounted products is not limited, provided ozone is not intentionally generated and not the primary air cleaning mechanism. For these products, ozone at the appliance is diluted by the relatively large volume of air moving through the duct or plenum. By contrast, products that purposely generate ozone are outside the scope of the US Safety Standards cited. As mentioned earlier, UL 867A is currently pending publication. Once published, this document will include requirements for Commercial and Industrial duct and plenum applications. The requirements will take into account ozone emissions measured near the source and the calculated dilution for a given installation and occupancy. These products will also be required to monitor ozone and signal an alert if ozone concentrations occur and may potentially exceed allowable values within an occupancy. Hardware and software reliability of the monitoring and alert system will be part of the requirements.

High voltage arcing

In recent years, air cleaning appliances have been designed to include electrically charged filter media to enhance capture of airborne particles. Due to the increased fire ignition risk associated with the presence of high voltage within air cleaning products, UL 867 has been updated to include an arcing resistance to ignition test for these product designs. The test causes arcing to appear across the filter media surface. The arcing shall not ignite the materials nor create a carbonised path that increases the risk of fire.

UV radiation

It is a generally known fact that prolonged exposure to ultraviolet (UV) radiation generated by the sun poses health risks and that it is prudent to take appropriate precautions. However, the risk of UV exposure from appliance sources is not as well appreciated. To limit user exposure to UV radiation, products are classified by their Threshold Limit Values for Chemical Substances and Physical Agents and Biological Exposure Indices (published by the American Conference for Governmental Industrial Hygienists, Table 2 “Permissible UV Exposures”). Under this classification, user exposure is limited to 0.1 µW/cm2 over an eight-hour period. UV radiation in excess of this value shall not be emitted from the appliance

UV degrades exposed polymeric materials, such as those used to insulate electrical conductors and enclose moving parts. For this reason, all polymeric materials exposed to direct or reflected UV radiation are required to be suitable for this UV exposure. Electrical components not suitable for UV exposure are required to be suitably shielded by a non-reactive material.

Conclusion

In summary, air cleaning products are now often much more complicated than the simple fan/filter units of the past. They employ technologies that help improve Indoor Air Quality, but also come with safety considerations that need to be addressed. An informed safety evaluation of these products can provide peace of mind when using the air cleaning appliance.

The writer is Manager, Principal Engineer, Appliances, Underwriters Laboratories (UL LLC). She can be contacted at Chante.W.Maurio@ ul.com

REFERENCE:

ANSI/AHAM AC-1-2006, Method for Measuring the Performance of Portable Household Electric Room Air Cleaners.

Copyright © 2006-2025 - CPI Industry. All rights reserved.