Improperly implementing energy-saving projects on centrifugal chillers can cause potential damage

In the January 2018 issue of Climate Control Middle East magazine, I wrote about an energy company implementing an energy-control strategy on centrifugal chillers that was ill-conceived and was causing massive damage to the centrifugal chillers. Here, I am again revisiting the subject of improperly implementing energy-saving projects on centrifugal chillers, as yet again I have come across an energy company that had good intentions but, ultimately, implemented a control savings programme on a centrifugal chiller plant, which was implemented incorrectly, thus causing occupant comfort issues and not meeting savings projections, resulting in detrimental chiller operation and potential catastrophic chiller damage.

We were requested to perform an in-depth analysis of a chilled-water plant, where an energy project was being performed by an energy-savings company. The company had implemented variable flow on the condenser and chilled-water pumps to achieve energy savings. Subsequent to the control implementation, the chillers were suffering numerous emergency shutdowns. We went through the chiller’s history and observed many chiller emergency shutdowns due to low condenser flow, low chilled-water flow and chillers shutting down on surge conditions. First and foremost, surge is one of the most detrimental conditions a centrifugal chiller can encounter and will cause catastrophic chiller compressor damage. Two technical terms need to be made clear in this article, so that the reader will fully understand how the improper control of condenser and evaporator flows will cause the chillers to surge, thus leading to extensive damage.

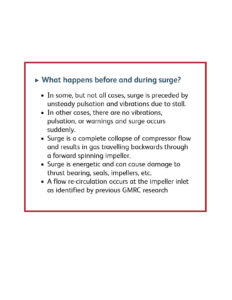

Again, our findings and alarm history review of the chillers proved the chillers were experiencing surge conditions. The following are the consequences of surge on centrifugal chillers…

Again, our findings and alarm history review of the chillers proved the chillers were experiencing surge conditions. The following are the consequences of surge on centrifugal chillers…

The preceding explanation is so the reader fully understands that surge must never occur and must be avoided at all costs in a centrifugal chiller.

The Problem

Our engineers determined that improper low condenser-water flow and improper low chilled-water flow, independently, as well as low condenser-water flow combined simultaneously with low chilled-water flow, were the causes of the surge conditions, surge emergency shut downs and low water flow shutdowns. A centrifugal chiller can suffer low-side (evaporator) surge and high-side (condenser) surge. Too low a water flow on either the high-side or the low-side will cause the centrifugal compressor lift to be outside its proper design operating map and, thus, the surge condition.

The solution

Variable condenser and evaporator flow have been proven to save substantial energy, and the energy company was correct in suggesting and implementing this type of optimisation programme; however, the control system and programming were not set up correctly and were missing important input and output information and controllers to correctly control the variable flow solution, thus causing chiller and comfort issues.

Variable condenser and evaporator flow have been proven to save substantial energy, and the energy company was correct in suggesting and implementing this type of optimisation programme; however, the control system and programming were not set up correctly and were missing important input and output information and controllers to correctly control the variable flow solution, thus causing chiller and comfort issues.

This type of variable flow strategy needs to have a robust state-of-the-art Chiller Plant Energy Control System installed/overlaid on the building automation systems (BMS) to operate the flows and towers correctly as well as protect the chillers.

The proper way to achieve maximum savings and proper safe control of a chilled water plant with variable condenser and chilled water flow requires the following: Typical BMS control equipment via fixed set points and schedules. These systems have limited knowledge of the actual equipment being controlled and how their performance changes at different operating conditions.

Case-in Point:

A BMS controls a cooling tower to a fixed 78°F, chillers are sequenced on once they reach full capacity, chilled water set point is adjusted based on a fixed time of day schedule and chilled water pumps are operated to maintain a fixed pressure. Typical strategies, such as the above, have been proven to consume as much as 75% or more energy at part load when compared to a CPECS (Chiller Plant Energy Control System), all as a result of the typical BMS system not having the calculation horsepower to make complex equipment performance calculations.

A BMS controls a cooling tower to a fixed 78°F, chillers are sequenced on once they reach full capacity, chilled water set point is adjusted based on a fixed time of day schedule and chilled water pumps are operated to maintain a fixed pressure. Typical strategies, such as the above, have been proven to consume as much as 75% or more energy at part load when compared to a CPECS (Chiller Plant Energy Control System), all as a result of the typical BMS system not having the calculation horsepower to make complex equipment performance calculations.

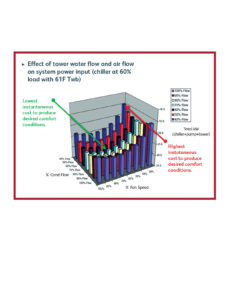

The CPECS software has complete knowledge of compressor, tower and pump performance characteristics, which it uses in real time to modulate control levels to all VFDs and provide the maximum level of system performance while respecting chiller flow, temperature limits and occupant comfort. The result is a central plant that operates in synchrony to deliver the highest possible total performance and equipment protection. Unlike other static optimisation strategies, a CPECS has the ability to self-correct chiller, tower and pump performance maps, such that regardless of wear and tear, inaccuracies in manufacturer’s data or off-design conditions, the plant will always run at peak efficiency. A CPECS goes past the central plant and out to the AHUs, continuously scanning specific data points in order to balance central plant performance with air side performance without sacrificing occupant comfort.

Any time a variable speed chiller plant operates at a capacity less than its maximum, there exists an opportunity for optimisation of set points and flows without compromising occupant comfort or process temperatures. ASHRAE studies conclude that air conditioning applications operate at part load over 96% of the time. The CPECS web interface displays actual plant performance in real time to the operator, placing utmost focus on efficiency.

Any time a variable speed chiller plant operates at a capacity less than its maximum, there exists an opportunity for optimisation of set points and flows without compromising occupant comfort or process temperatures. ASHRAE studies conclude that air conditioning applications operate at part load over 96% of the time. The CPECS web interface displays actual plant performance in real time to the operator, placing utmost focus on efficiency.

All CPECS control systems have the ability to remotely warn of equipment failures or poor efficiency through a built-in email server. Each installation deploys with a full enterprise SQL database that resides on the site (all data owned and under control of the plant owner).

A CPECS system may be delivered as a complete controls package with VFDs, control cabinet, touch panel, I/O hardware or as a networked smart box deployed on the BAS backbone (BacNet, Lon, Modbus and N2 capable). CPECS systems are factory designed and tested, guaranteeing quick installation and trouble-free startup.

CPECS achieves optimisation through:

CPECS features:

CPECS has achieved annual total plant operating efficiencies of 0.48kW/tonne (7.3 COP) and better. These results far exceed today’s energy efficiency code requirements.

We recommended all variable chilled and condenser water flow be stopped immediately until a CPECS system was engineered, designed and installed at the chilled water plant, because without a CPECS system installed it would be impossible to achieve maximum savings and protect the chillers properly. We recommended the CEPCS system installed at subject chilled water plant should be equipped with its own flow, electrical and temperature metering, which will enable the owner and the energy company to view plant efficiency in real-time. In addition to electrical savings, reductions of up to 10% in tower water consumption can be realised with the CPECS system.

CPECS plants offer connectivity to:

In closing, this energy-savings company did have a solution that would save energy; however, it was not engineered and implemented properly. Centrifugal chillers and plants are very sophisticated and expensive, and in my opinion, when an energy-saving solution is to be implemented on a chiller or any ancillary equipment, the owners and energy company should work with a proven chiller specialist energy solutions company to be fully involved in the design and implementation of the solution, as a proven chiller specialist company has the in-depth knowledge and experience to execute these projects to their full savings potential while keeping chiller reliability and safety, first and foremost.

Dan Mizesko is the Managing Partner of Al Shirawi US Chiller Services. He can be contacted at dan@uschillerservices.com.

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Copyright © 2006-2025 - CPI Industry. All rights reserved.