Case study to find out the efficiency and effectiveness of Airfree’s patented Thermodynamic Sterilising System (TSS) on fruit, vegetables and perishables.

A study was conducted to find out the efficiency and effectiveness of Airfree’s patented Thermodynamic Sterilising System (TSS) on fruit, vegetables and perishables. The result showed that the system had a proven advantage over ordinary cooling units.

The Thermodynamic Sterilising System patented by Airfree works on basic principles of physics. Hot air rises through the sterilising system. This creates a convection pull to bring new air into the system. This process is assisted further by airflow in commercial chiller units. Once inside, the TSS technology incinerates 100% of micro-organisms at an internal temperature of 200° Centigrade. The sterilised air is then cooled and returned to the room, without increasing the overall ambient temperature.

Although the internal temperature is 200°C, thanks to cooling and the small scale on which the system operates, two units emit the equivalent kilojoules of heat as one person breathing, and the system does not increase the temperature in controlled facilities.

CASE STUDY

The study was conducted at Shokri Hassan Trading Company (SHTC), Dubai, from October 4 to 28, 2010.

Aim: The aim of the test was two-fold:

A) To formally assess the viability of installing the Thermodynamic Sterilising System throughout all SHTC chilled storage areas by measuring increase in shelf-life of Airfree in a fully functional commercial chiller.

B) Investigating the system’s potential to allow for an increase in chiller temperature settings and, thus, reducing cooling and utility bills.

THE TEST

Duration: 25 days

Subject: Peaches, Class II Grade AA-AAA

Origin: Turkey

Test chillers: Four – Berry Room (a special storage area where perishable and expensive produce is stored), installed with Airfree, and three chillers without Airfree installation

Chiller sizes: Berry Room: 118.485m³ (5.492m x 4.727m x Height 4.564m)

Chiller 1: 297.1m³ (13.815m x 4.712m x Height 4.564m)

Chiller 2: 162.89m³ (9.812m x 6.505m x Height 2.552m)

Chiller 3: 159.05m³ (9.807m x 6.335m x Height 2.552m)

Variables recorded:

1) Fruit temperature: degree Centigrade (measured using Raytemp 4 Laser thermometer)

2) Chiller temperature setting: degree Centigrade (recorded from the SHTC chiller computers)

3) Chiller ambient temperature: degree Centigrade (recorded from the SHTC chiller computers)

4) Chiller wall temperature: degree Centigrade (measured using Raytemp 4 laser thermometer)

Method:

Trays of peaches from SHTC’s regular stocks were used, selected from the same batch at random and placed in four test chillers on October 4, 2010. The Berry Room was Airfree-installed and Chillers 1, 2 and 3 were not installed with Airfree. Photographs and the aforementioned variables were taken initially every second day and, then, daily up until October 28, 2010.

Purpose:

SHTC had its Berry Room installed with 3 x Airfree WM50+ units in stainless steel (wall-mounted) in April 2010, and three chillers were without Airfree. A significant difference in terms of reduced spoilage was noted by the management, following the purchase and installation of Airfree units in an area where the most perishable and expensive produce is stored, namely, the Berry Room. A further study was requested to assess the viability of further investment and extended installation of the system.

SHTC had its Berry Room installed with 3 x Airfree WM50+ units in stainless steel (wall-mounted) in April 2010, and three chillers were without Airfree. A significant difference in terms of reduced spoilage was noted by the management, following the purchase and installation of Airfree units in an area where the most perishable and expensive produce is stored, namely, the Berry Room. A further study was requested to assess the viability of further investment and extended installation of the system.

CONCLUSIONS

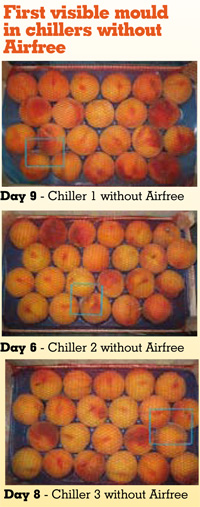

Shelf life: The peaches in the Berry Room, the chiller with Airfree installed, remained in a saleable condition for the entire 25-day period, with no signs of mould or decomposition. Peaches in all three control chillers were affected by mould and were decomposed.

In Chiller 2, mould was visible by Day 6.

In Chiller 3, mould was visible by Day 8

In Chiller 1, mould was visible by Day 9.

It could be concluded that Airfree extended the shelf-life of fruit between 16 and 19 days in the 25-day study. The implication of this was that it extended the shelf-life of the peaches by more than four times in Chiller 2, more than three times in Chiller 3, and more than 2.5 times in Chiller 1, averaging more than three times increase in shelf-life.

Savings through reduced cooling and increased chiller temperatures:

It was noted that the average temperatures, as recorded in Chiller 1, were colder than the Berry Room and, thus, the peaches should have lasted longer. Airfree achieved shelf-life extension in warmer conditions in the Berry Room than in Chiller 1. Despite running at an average ambient chiller temperature of 2.65°C higher, the shelf-life was over 2.5 times longer. This figure is reconfirmed by the fruit temperature statistics – the peaches in the Berry Room were on an average 2.63°C higher than in Chiller 1.

It can, therefore, be concluded that using the Thermodynamic Sterilising System, a company storing fruit and vegetables can increase temperature settings in their chillers by at least 2.5°Centigrade and, still, achieve shelf-life extension of at least 2.5 times.

Peaches from Chillers 1, 2 and 3 were discarded on Day 25 at the end of the study. Peaches from the Berry Room were retained for the purposes of further research into the full shelf- life extension possible, using the system. These peaches were inadvertently discarded on Day 32. But it was noted that they were still mould-free when pictures were taken earlier that day. Therefore, it can be concluded further that the Thermodynamic Sterilising System extended the shelf-life produce by between 23 and 26 days, indicating more than 3.5 to five times of extended shelf-life over produce stored without the system.

Peaches from Chillers 1, 2 and 3 were discarded on Day 25 at the end of the study. Peaches from the Berry Room were retained for the purposes of further research into the full shelf- life extension possible, using the system. These peaches were inadvertently discarded on Day 32. But it was noted that they were still mould-free when pictures were taken earlier that day. Therefore, it can be concluded further that the Thermodynamic Sterilising System extended the shelf-life produce by between 23 and 26 days, indicating more than 3.5 to five times of extended shelf-life over produce stored without the system.

Copyright © 2006-2025 - CPI Industry. All rights reserved.