In this eight installment of a multi-part series on air filtration, like food and water, clean air should be regarded as a human right, and ensuring this is the shared responsibility of filter manufacturers, researchers, test laboratories and HVAC designers, says Iyad Al-Attar.

We do our utmost to earn a bonus, a raise or possibly an award for our achievements, because they are tangible and recognisable. But if our achievements had an invisible impact which could not be easily quantified, then would we still put ourselves out? Would we not feel disappointed and worried that an unseen impact went unrecognised?

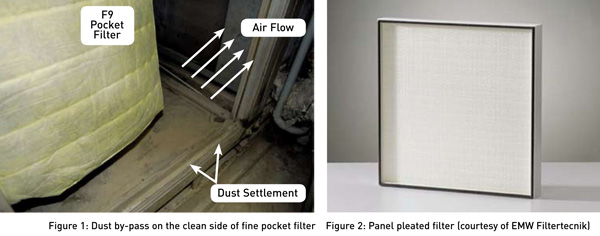

Extending the analogy to the air we breathe, this seems to be the case when it comes to implementing air filtration solutions and addressing filter performance, which is microscopic in nature. Filters are installed behind the closed air handling unit doors and require proper handling to ensure a leakage-free installation. Figure 1 shows dust settlement after F9 pocket filter (95% efficiency) on the backside of the filter, which is supposed to be considered the clean side. If air has gone completely through the filter, it should be impossible to detect visible dust. But its presence highlights the issue of leakage from the filter, installation frame and/or from the air handing unit door.

Surely, if we outsource a HEPA filter (Class H13, DIN1822), then it is reasonable to expect that the filter will perform as H13 filter. This is because when we see two HEPA filter products with the same efficiency label, our brain unconsciously dictates to us that the resemblance of the images reflects similarity of performance. But it might come as a surprise to us that under similar operating conditions, these two filters may behave differently. If this is not difficult enough to digest, consider a filter with a specific rated efficiency at a given flow rate. If the end-user subjects the filter to higher face velocity other than the one rated, the test reports accompanying the filter will neither be representative nor totally relevant.

HANGING THE HAT

Let’s hang our hat on the flow rate, as increasing it consequentially increases the face velocity and affects filter performance characteristics, namely pressure drop and efficiency. When air velocity increases, particles could get detached after they have attached themselves to the fibre surface. Such re-entrainment will lower the overall filter efficiency, which is a more pronounced effect in coarse-medium efficiency filtration.

Increasing the flow rate would also lead to increase in the pressure drop and elevate energy consumption. Needless to say, excessive use of flow rate will distort filter elements and may deform the filtration media, leading to substantial loss in surface area and further contribute to the increase of face velocity. In such operating conditions, the performance reliability is jeopardised and the filter will pose a major threat to the HVAC equipment and human occupancy. In fact, filter elements may collapse and dust-loaded pleated filter panels may rupture, causing a major contamination to the entire indoor space. Therefore, caution must be exercised when considering the operating conditions, specifically the rated flow rates, to ensure performance reliability.

The immediate question that would come to mind is, how do we know how the filter is operating efficiently since it is not readily visible? It is evident that occupants hardly see an air filter in operation. This is because the performance of air filters is microscopic and is impossible to quantify by seeing an air diffuser or by inhaling the indoor air. Therefore, filter efficiency is the shared responsibility of the filter manufacturers, researchers, test laboratories and HVAC designers. Filtration and maintenance companies are expected to apply air filtration solutions and the associated products in the fullest sense of the term. Thus, our commitment to adhere to the rules and regulations of filtration should always be our main priority.

ESTABLISHING AIR FILTRATION KNOWLEDGE

The behaviour of clean air filter has been well-established and specially reviewed by several authors (Davies, 1973; Brown, 1993). However, literature on loaded filter performance is still rather limited. This poses many challenges, primarily due to the dynamic flux of several time-dependent parametres affecting filter performance, as it tends to get loaded with dust. Filtration experiments, therefore, need to be conducted with great accuracy, using specific instruments to obtain representative and reproducible results. Recent advancement in nano-scale particle counter will open up a whole new research platform, as filtration discussion for so many years has been limited to the submicron scale.

NEED FOR EXPERIMENTAL RESEARCH

If we consider most of the theoretical or experimental research in the past, we will find that their scope was limited to flat filters and small-scale pleated panel HEPA filters in panel configuration, as shown in Figure 2. Although some studies were conducted on the pleated filtration media, the literature available on pleated panels of HEPA filters is rather limited and is mainly based on numerical approaches used for performance analysis. Clearly, further research will prove invaluable for the understanding of dust-loaded filter performance and would reveal more in-depth analysis as far as filter clogging is concerned.

There is hardly any application nowadays that does not use pleated filter. However, we still rely on studies based on flat sheet testing, and then extrapolate the results in the hope of understanding the overall performance of a pleated cartridge filter.

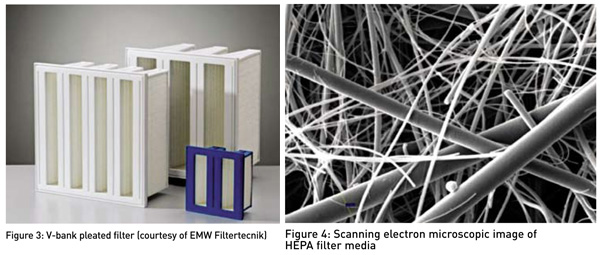

When a flat sheet medium is pleated and then constructed in a filter frame, the dynamics of filter performance begin to vary when comparing flat versus pleated filter. It would also continue to vary when altering the design to provide extending surface area through a V bank design, as shown in Figure 3.

Clearly, there is so much more that needs to be discovered and expected. And as much as our libraries are filled with material regarding experiments on clean flat sheet media, the research on pleated filter cartridges sadly falls short of expectation, and needs to get the performance parameters, as also the attention they deserve.

Clearly, there is so much more that needs to be discovered and expected. And as much as our libraries are filled with material regarding experiments on clean flat sheet media, the research on pleated filter cartridges sadly falls short of expectation, and needs to get the performance parameters, as also the attention they deserve.

During dust loading, the filter performance characteristics vary as dust continues to be loaded into the filter and its performance becomes even more complex to assess. Temperature and relative humidity are very important parametres affecting filter performance. However, accurate and comprehensive understanding of these parametres on filter performance has not yet been completely established. Therefore, it is essential to be able to predict the filter performance as far as pressure drop and efficiency are concerned in temperature and relative humidity settings.

Several questions come to mind regarding how significant the influence of the relative humidity is on filter performance. The most important one is: Is it more pronounced as the particle size decreases? Further, influence of the hygroscopicity of the aerosols on the evolution of the fractional efficiency and pressure drop across the filters must certainly be considered prior to reaching any sweeping conclusions.

COMPLEXITY OF THE AIR FILTRATION PROCESS

Evidently, the filtration process is complex and its performance assessment is influenced by a constant flux of several parametres, such as face velocity, filter medium properties, filter design, aerosol characteristics, ambient conditions and dust types and their loading conditions. Thus, air filter performance evaluation lies in the simultaneous variations of all these parametres. In fact, the first challenge that emerges in any filtration study is the random structure of filtration media, as shown in Figure 4. Other various assumptions are made in order to simplify the evaluation process of air filters. However, this evaluation can be viewed as a performance indication rather than exact filter behaviour.

THE ETHICAL OBLIGATION

In conclusion, one can say that providing the finest air filtration techniques is a commitment that researchers and manufacturers have towards humanity that goes far beyond any commercial objectives. Clean air should be regarded as a human right, just like food and water, and we owe it to the coming generations. Therefore, we have to do our utmost to ensure that clean air is a “product” we can preserve.

With mounting pressures of environmental changes and epidemic outbreaks, our obligation of providing clean air to humanity is an ethical one, rather than a mere technical issue.

The writer is Regional Director, Middle East, and International Consultant, EMW Filtertechnik, Germany. He can be contacted at iyad. al-attar@emw.de

References:

Davies CN , 1973. “Air Filtration”, Academic Press, New York.

Brown RC 1993a. “Air filtration: an integrated approach to the theory and application of fibrous filters”, Pergamum Press, Oxford. User Guide. Page reference: 8

Copyright © 2006-2025 - CPI Industry. All rights reserved.