In Part 11 of the series on air filtration, Dr Iyad Al-Attar explains the three vital stages of air filtration selection and argues that efficient air filtration is a concept whose time has come.

Though air filtration is a silent worker, doing its job quietly in the background, little attention is paid to its selection and gauging its efficiency.

Making appropriate filter selection requires a comprehensive understanding of the underlying parameters influencing, not only the air filter itself, but also the surrounding environment.

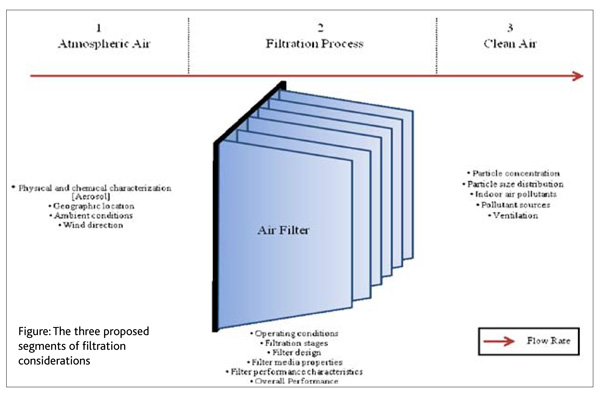

The right selection of an air filtration system needs to go through three stages:

When the filtration process is addressed, most people are interested only in the filter’s output, namely, clean air. Not much emphasis is placed on particle collection mechanisms, material properties, such as packing density and fibre-size distribution, which would greatly contribute to the filter performance characteristics – efficiency and pressure drop. But these preliminary steps are equally significant. Therefore, it is advisable and beneficial that, prior to engaging in filtration selection, importance is given to the three main steps of selection, as illustrated in the Figure, opposite page.

AIR FILTRATION SELECTION

Stage 1:

The first thing to be considered is the physical and chemical characteristics of the aerosol. This is of a great importance from the point of view of filtration, environmental hygiene, medicine and toxicology. For example, dust poses a problem once it becomes airborne and is introduced into air filters. Therefore, the crucial step in conducting measurements is to obtain a representative sample of the aerosol under study.

The process of getting an estimate of and an insight into air filter performance cannot be completed without taking into account ambient conditions, such as temperature and relative humidity. They greatly affect the filter performance, and may also influence the filter design parameters and filter media selection.

Another aspect which needs to be considered is the geographic location. Atmospheric aerosol composition varies noticeably, depending on the selected position of the sampler relative to the pollution source originator and meteorology1. For example, when we examine the contaminant types, size distribution and concentrations near an airport, we would consider the jet engine exhaust as an additional particle generator. If the airport is surrounded by a desert, then the dust concentration is expected to be higher compared to other areas. Another example is a filter installation in the downtown area of a city with high-rise buildings. With busy traffic of heavy and light vehicles, their exhaust will certainly pose a great challenge to air filters installed in the air handling units. The high-rise buildings could act as street canyons to trap pollutants to further contribute to the number of contaminants and concentrations challenging air filters.

Another important example is a hospital where it is absolutely imperative not only to condition the air prior to introducing it indoors, but also prior to exhausting it to the surrounding neighbourhood.

Stage 2:

The second consideration is the filtration process itself. Prior to making any further decisions in filter selection based on the characterisation of atmospheric pollutants – physical and chemical – in Stage 1, we need to decide what sort of contaminants have to be removed from the air stream and at what level of efficiency. Assuming that atmospheric dust is the prime concern, the second issue to be addressed would be ‘dust concentration’, as it would determine whether or not the filtration stages are needed.

Further, it is not possible to make an appropriate filter selection without considering the operational flow rate. Once the filtration stages are determined, the focus needs to shift to the filter type and design, to provide the required surface area and pressure drop for ensuring efficiency.

A critically important parameter in filtration is filter’s permeability. It is more relevant to consider permeability of the filter cartridge for evaluation than the flat sheet medium when considering full scale operations. This is because flat sheet permeability may be subject to alteration after pleating and constructed in the filter cartridge, which would lead to overall permeability reduction and consequential pressure drop increase.

Another advantage of characterising pollutants is that it helps determine whether outdoor or indoor pollutants are solid particles or gaseous pollutants. In the case of solid particles, appropriate mechanical filtration is sufficient to remove the particles. In gaseous pollutants, an adsorbent filter stage, such as activated carbon, is required.

It is also important to consider the life cycle of the filter, if the concentration, flow rate and the filtration stages have been chosen to provide the intended efficiency. In addition to the filter media types, one should consider several other parameters, such as the packing density, average fibre diametre, fibre size distribution and its thickness. Needless to say, filtration media property, such as water repellency, is greatly needed for HVAC and gas turbine applications for coastal installations. Clearly, purchasing managers cannot merely regard the initial cost of the filter as the main selection criterion. In fact, a precise filtration plan is needed and should be the top priority, and not just the cost of the filter. In short, several important questions need to be asked:

Stage 3:

The third stage is mainly a process of verification that the proposed filtration solution has, in fact, performed to the level it was supposed to do. In clean room applications, the allowable presence of certain particle size distribution will determine the integrity of the air filter performance. Another important challenge to filter performance assessment and improved indoor air is infiltration, which is defined by ASHRAE2 as the unintentional or accidental introduction of outside air into a building, typically through cracks in the building envelope and through use of doors for passage. Equally important is leakage-free installation in both air filter frames (header and holding) to ensure that the clean air produced is preserved.

TECHNIQUES TO CONTROL AIR CONTAMINANTS

Tackling air contaminants could range across the following parameters:

MEASURING IAQ

In this regard, awareness regarding clean air and the methods to either provide it or preserve it are also of paramount importance. Such awareness is not only beneficial to building owners, maintenance directors, engineers and their crew, but also to human occupants.

In this regard, quantifying whether or not a building has an indoor air problem by the number of complaints the building manager receives, is an old-fashioned gauge to measure indoor air quality. The million dollar question is, why do we wait until symptoms emerge to put together an action plan to tackle the problems of indoor air quality? There are many air pollutants present in the indoor air with concentrations below the threshold that would trigger our human response system, causing irritation or health problems. It is imperative, therefore, that pollutant concentrations are measured on a regular basis to determine if a certain concentration is soon going to exceed the specified threshold. We cannot allow contaminants to pose a threat to indoor space and its occupants, knowing that our homework is merely of a preventative nature.

CAMPAIGN FOR ZERO TOLERANCE

We design and construct indoor spaces and lock ourselves in them most of the time. We seem to be very tolerant in allowing unpleasant and harmful pollutants to invade our indoor spaces, multiply and elevate their concentration, until our human immune system triggers health issues. Air contamination requires early detection in order to identify, control and then eliminate it before it gets us.

Certainly, our responsibilities do not end by merely investigating the interrelated filtration performance parameters to make appropriate filter selection. It goes far and beyond this to control the indoor and the outdoor pollution sources and propose the filtration line of defense to ensure clean air can both be produced and preserved.

Today, we are equipped with state-of-the-art spectroscopic analytical technologies, lasers, and powerful computers – tools that were not available 60 years ago, though many advances were made at the time. This is simply to state that human psyche is ready, capable and willing to make technological dreams come true.

Would we have built gigantic shopping malls without power plants to generate the required energy output? Would we have even considered such projects without the existence of HVAC systems? Throughout history, human beings have always had ambitious dreams and have attempted to achieve, not only the improbable, but also the impossible.

There have been many human aspirations that took a long time before they were realised. The helicopter can be cited as an example. The first major development can be traced back to the early 1480s when Leonardo da Vinci produced a machine design concept for vertical flying3. However, it was not until 1936 that the first helicopter came into operation, and subsequently reached full-scale production in 19423a. Today, there are many possibilities for innovations that would make history in the future. But we cannot wait for four centuries to see them take shape. Similarly, the innovations in the field of air filtration have to happen now.

The writer is Regional Director, Middle East, and International Consultant, EMW Filtertechnik, Germany. He can be contacted at iyad.al-attar@emw.de

References:

1 Analytical Chemistry of Eerosol, edited by Kvetoslav Rudolf Spurny, Lewis Publisher, 1999.

2 Fundamentals Volume of the ASHRAE Handbook, Ch. 27, ASHRAE Inc, 2005.

3 & 3a www.wikipedia.org

Copyright © 2006-2025 - CPI Industry. All rights reserved.