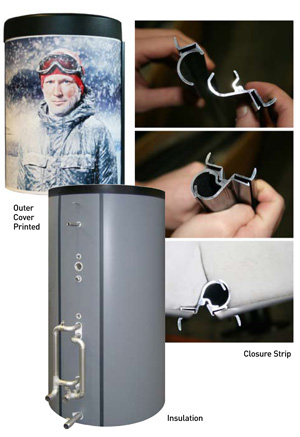

Ecotherm has announced developing an insulation system for hot water tanks from 200 to 20,000-litre capacity with fibre-fleece insulation and patented closure strips, which it claims is the result of more than two years of development.

According to Ecotherm, fibre-fleece has been used for several years now in the clothing industry and the automotive industry because the material fits the shape of the storage tank perfectly and the “chimney effect” can be prevented.

Highlighting the important advantage of the product, Project Engineer Christoph Lehner said: “The insulation system with polyester fiber-fleece provides up to 30% less heat loss in standby mode compared to conventional insulations. We offer a complete production system for companies that want to establish an insulation production. For an efficient production at least 5,000 insulations per year are required.”

The manufacturer lists the following product features and advantages:

The manufacturer lists the following product features and advantages:

Copyright © 2006-2025 - CPI Industry. All rights reserved.