Claiming that their explosion protection opens new areas of applications for EBE filter enclosures, for example, in the food and beverage industries where organic dust can occur during milling and can produce explosive atmospheres, GEA has announced expanding its Delbag EBE filter enclosure range by addition of a version designed for use in areas subject to explosion hazards.

The company lists the following product features and benefits:

The company lists the following product features and benefits:

- The Delbag EBE air-duct filter enclosures are certified for use in hazardous-area zones 20, 21, and 22, as well as for areas of Zones 0, 1, and 2, that are endangered by dust explosions.

- They may likewise be employed in plants with gas, mist, and vapours in the explosion groups of Categories IIA and IIB, as well as for operation in Zones 1 and 2 with gases of Explosion Group IIC.

- EBE filter enclosures are effective not only for air purification in the electronics industry, in processing plants and in libraries and museums, but also for bakery and mill applications and with the production of tobacco and spirits.

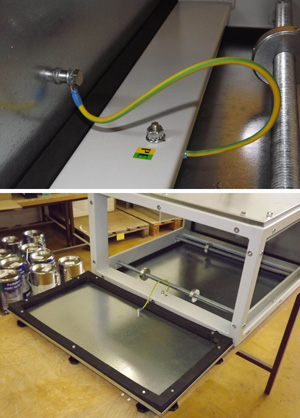

- Their modular design enables combination of the systems to provide a variety of facility capacities.

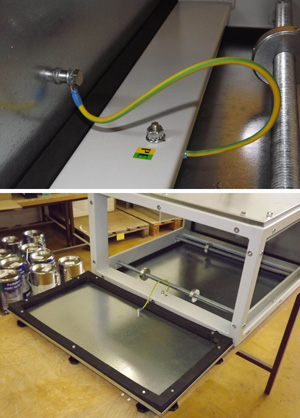

- The airtight enclosures are made of galvanised sheet steel or stainless steel with brazed or welded profile connections, effective for suction- or pressure-side operations (maximum 2,000 Pa).

- They are fitted with filter media from Classes G3 to H13, with various filter sizes.

- Several filter stages can be combined in a series.

- Extensive accessories are available for the filter enclosures, such as pressure drop measuring devices, connection fittings and protective grids.

The company lists the following product features and benefits:

The company lists the following product features and benefits: