Nimal Amukotuwa discusses how it is possible to provide dehumidified air to buildings at a low green cost, without compromising on thermal comfort

I may sound trite when I say this, but building ventilation is eminently essential for maintaining the air quality in a building to give occupants a comfortable living experience. The guidelines for ventilation and IAQ (indoor air quality) of buildings are found in ASHRAE Standard 62 (Standard 62-1 and 62-2). The International Mechanical Code (IMC) also provides guidelines relating to building ventilation.

The guidelines provide the ventilation rates for various types of building occupancies, with an eye on occupant comfort.

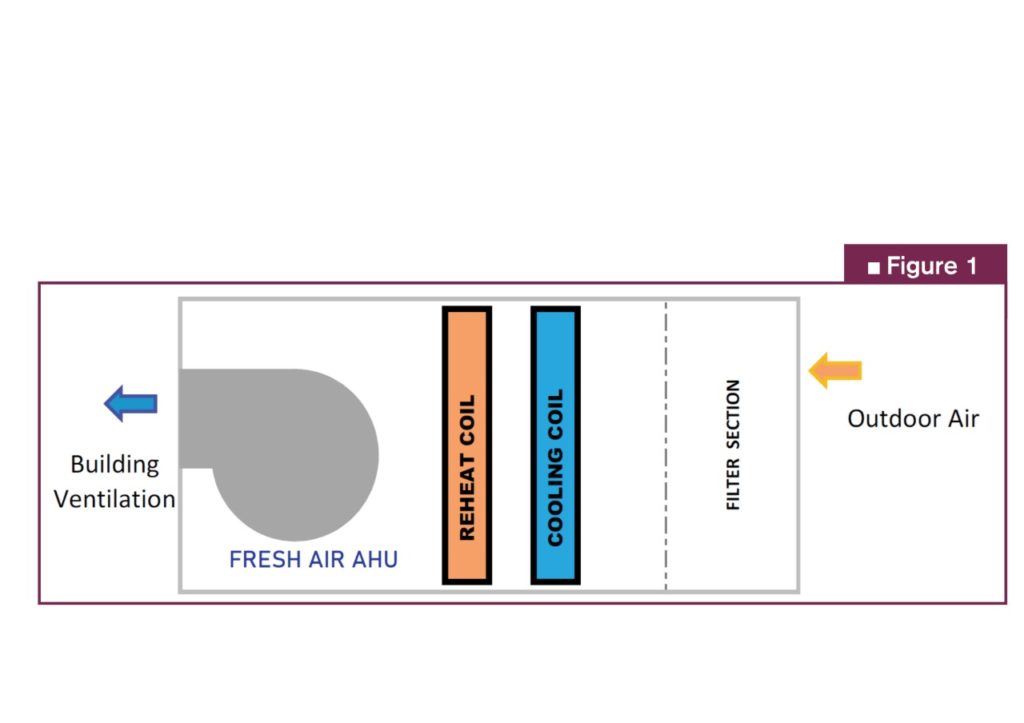

So, what were the building ventilation systems or practices followed in Dubai prior to the energy crisis? The systems or practices in earlier days revolved around providing dehumidified ventilation to the building, where the supply air temperature was reheated. It was a time when energy recovery was not considered or used.

The reheating was achieved through either electric heating coils or hot water coils that were installed in the fresh-air- handling units (FAHUs). Figure 1 indicates the general layout of an FAHU installed during that period.

AFTER THE ENERGY CRISIS

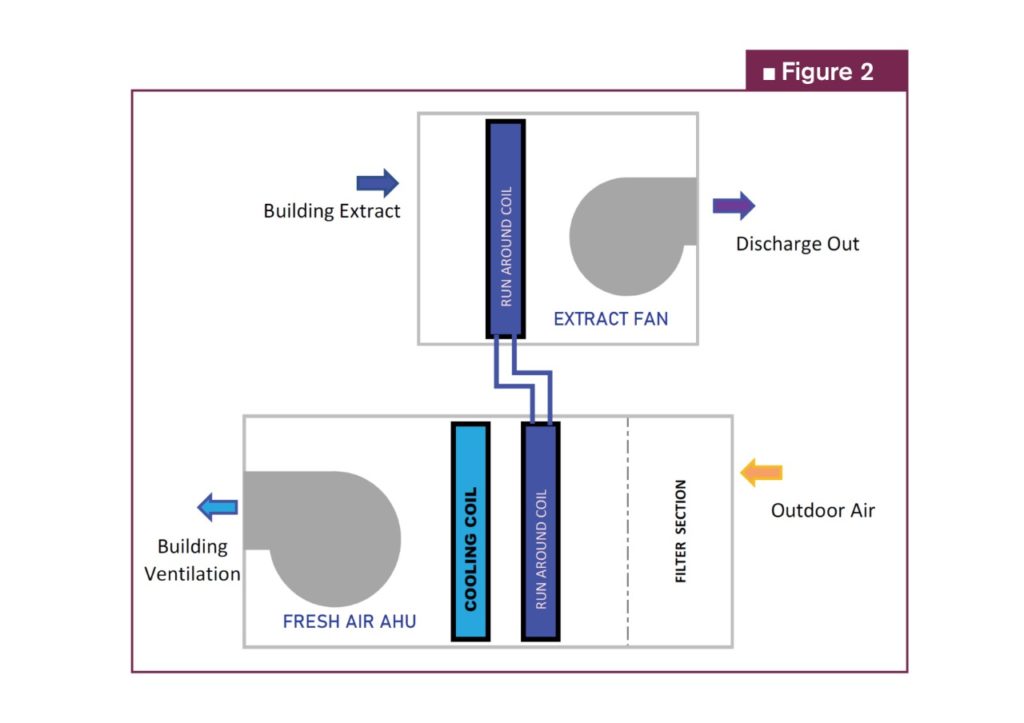

With the onset of the energy crisis, the building ventilation system transferred the high-ambient air thermal energy to the extract discharged from the building as a means of energy recovery. The energy transfer was usually performed with run- around thermal transfer coils.

Due to the energy consumed by reheat coils, reheating was discontinued, and the dehumidified air was supplied around 13 degrees C to 14 degrees C into the space. Figure 2 indicates the general layout of an FAHU installed during this period.

CURRENT INSTALLATIONS

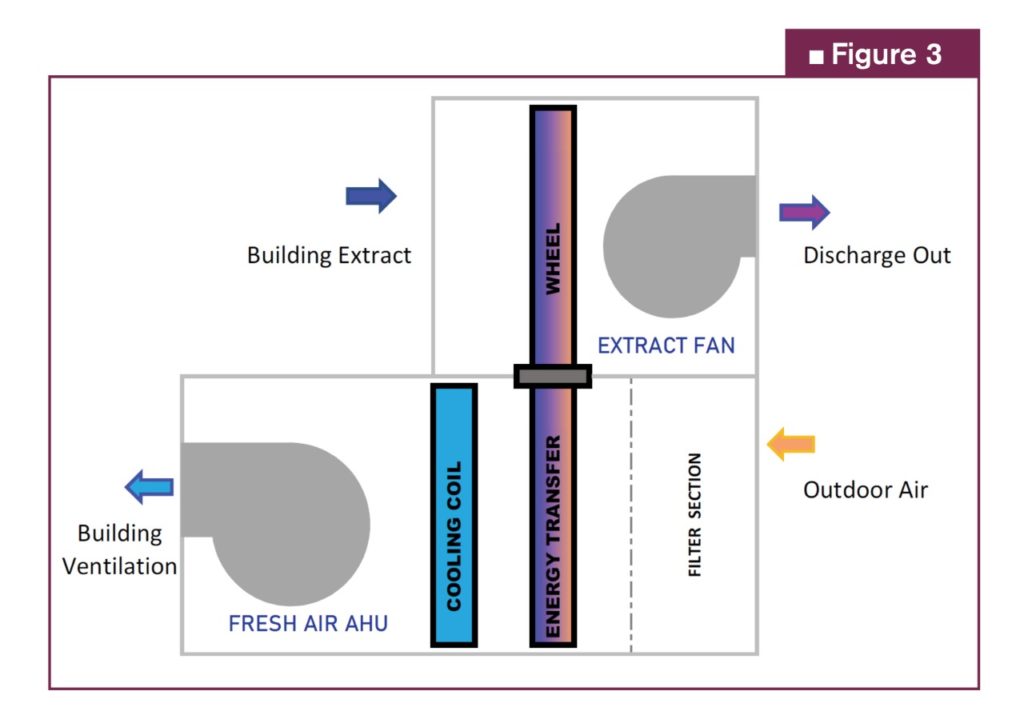

As per Dubai Municipality requirements, the current installations are fitted with recovery wheels that transfer sensible heat as well as latent heat (moisture), due to the desiccant coating on the wheel.

Again, the reheating is not performed. Even with the latent transfer through

the wheel, the FAHU cooling coil requires dehumidifying the ventilating air to reduce the moisture content to the desired level, some of the times. This process requires the air to be cooled to around 13 degrees C.

DOES THE CURRENT INSTALLATION PRACTICE MEET ASHRAE GUIDELINES?

Do the current installations in Dubai and other coastal areas in the UAE, where the ventilation is supplied at around 14 degrees C, or lower, directly to the conditioned areas, meet the ASHRAE Standard 62 (62-1 and 62-2) guidelines?

In my opinion, they do not. My opinion is based on interpreting ASHRAE Standard 62 as “providing a guideline to the ventilation to address health and comfort requirements”. Supplying cold air that is not controlled by the space thermostat cannot be considered as providing a comfortable air supply.

In Dubai, the number of hours per annum, where the moisture content of the ambient air is above that of the desired level in an occupied conditioned space is over 5,000, and the ambient dry bulb temperature over 24 degrees C is around 6,280 hours. The energy transfer wheel would not be able to bring the ambient air to the required or desired level for many of those hours; therefore, the cooling coil requires to cool and dehumidify the air. To achieve the required moisture removal, essential for ensuring indoor occupied comfort conditions, the ambient air needs to be cooled below 13 degrees C or lower. When air at temperature is delivered to the conditioned space, the occupants would feel cold, as the air conditioning units serving the space have no means of controlling the temperature of the air delivered by the ventilation system.

The undesired cooling from the ventilation supply is felt more prominently in residential buildings, where the ventilation air requires dehumidifying (removal of moisture) in the late evening and early mornings. During these periods, the space load is low, and air conditioning units serving the area are switched off from the thermostat, but the space is cooled further by the ventilation supply, causing many occupants to complain.

ENERGY-EFFICIENT SOLUTION

In the past few months, I have been requested to provide a design to replace 12-year-old ventilation systems in two buildings in the Bur Dubai area, both independent of each other. At the time of the original installation, energy recovery from the building extract was not considered, and the existing ventilation and extract risers were not installed adjacent to each other. Therefore, using an energy-recovery wheel was not possible, and the available solution was to use run-around thermal coils.

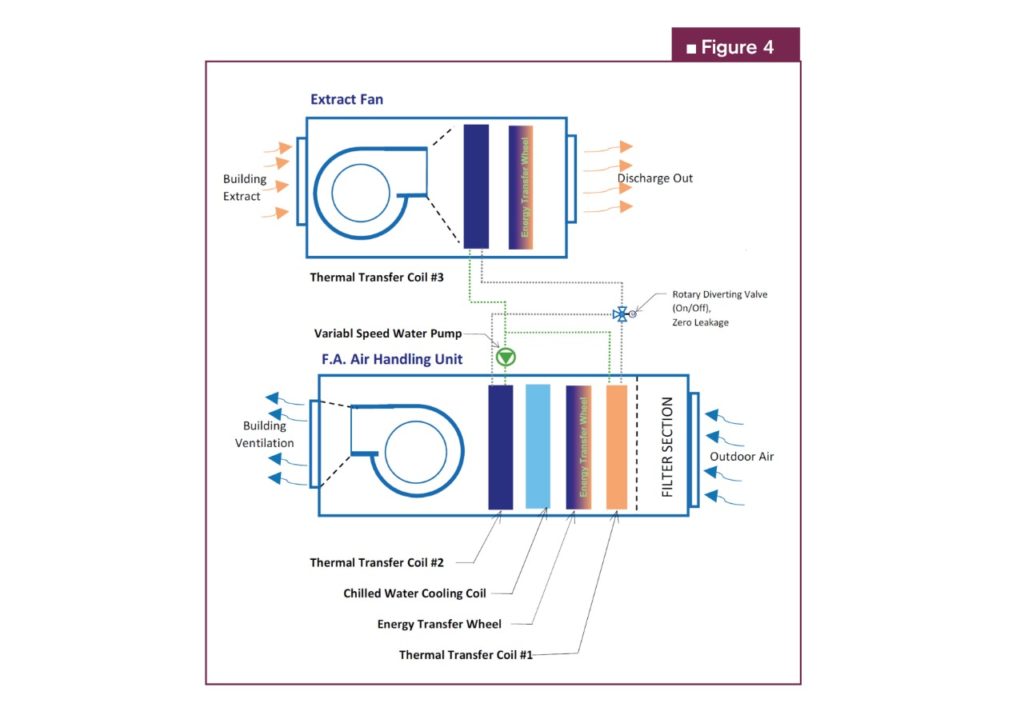

To overcome the issues – that is, supplying air at around 13 degrees C to the conditioned space – the ventilation air was reheated in an energy-efficient manner by recovering either the ambient air or extract air temperature, with run-around thermal transfer coils, as shown in Figure 4.

In the Bur Dubai projects, the supply air was reheated to around 17 to 17.5 degrees C. The temperature was controlled with a variable-frequency drive pump and a three-way control valve. The operation of the three-way on/off control valve

is through a differential temperature

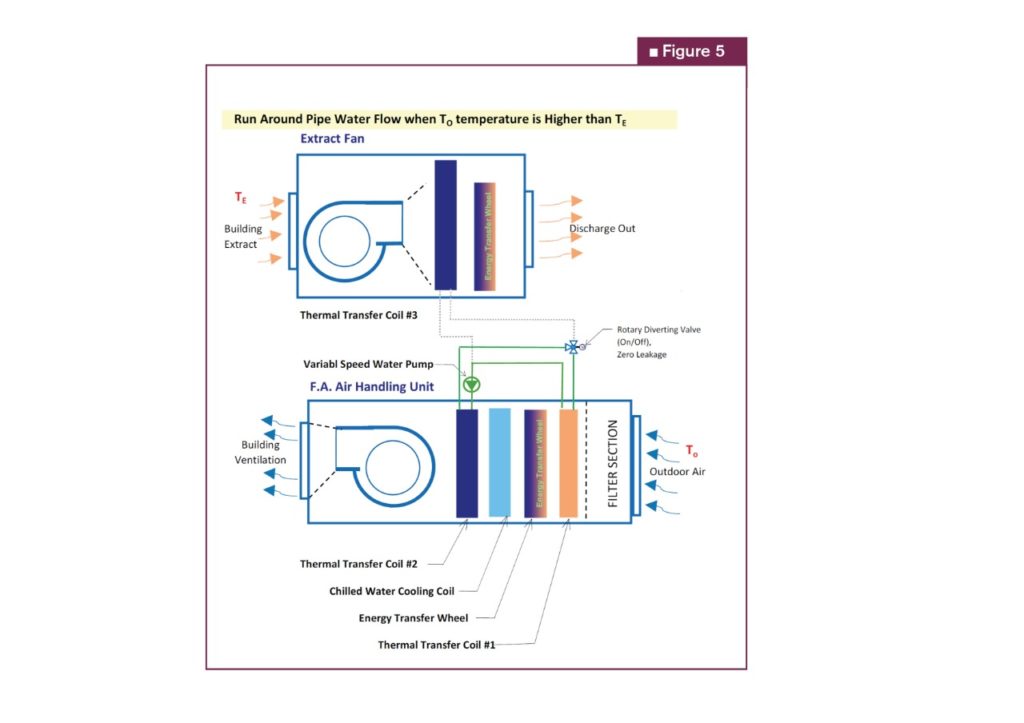

In the Bur Dubai projects, the supply air was reheated to around 17 to 17.5 degrees C. The temperature was controlled with a variable-frequency drive pump and a three-way control valve. The operation of the three-way on/off control valve is through a differential temperature controller, which switches the flow either to the Thermal Transfer Coil #1 or to the Thermal Transfer Coil #3, from Coil #2 – that is, common for both conditions. Figure 5 indicates the flow, when the ambient temperature is higher than the building extract temperature.

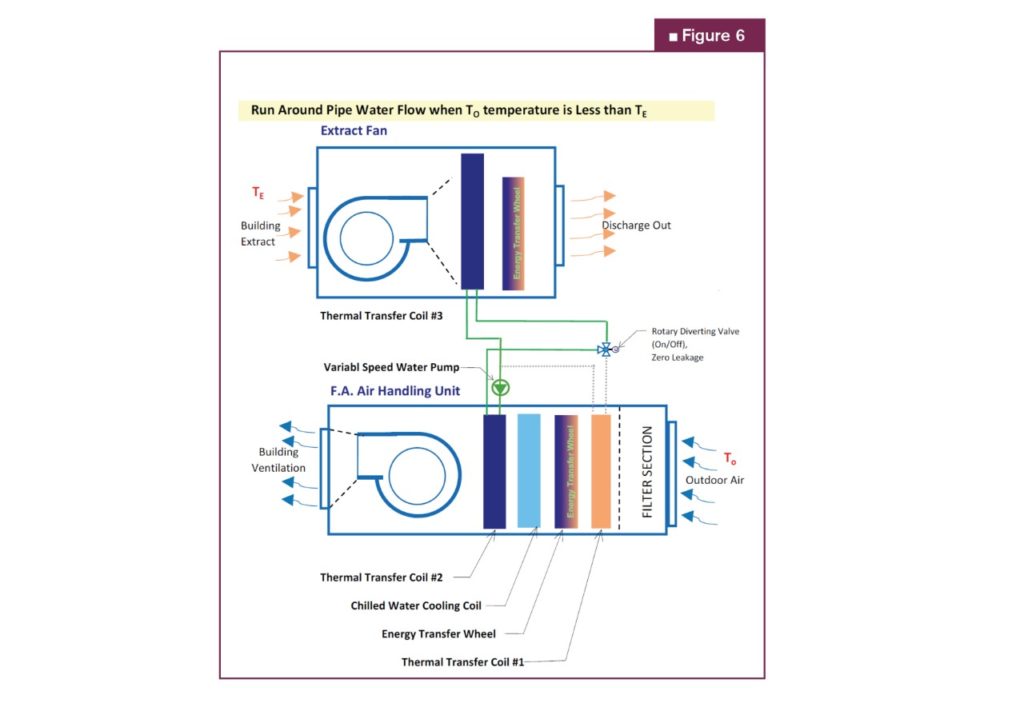

The flow, when the ambient temperature is lower than the building extract is indicated in Figure 6.

Nimal Amukotuwa is an independent consultant based in Dubai. He can be contacted at namukotuwa@gmail.com.

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Copyright © 2006-2025 - CPI Industry. All rights reserved.