EcoPower’s hybrid ventilation system helps Australia’s Caddy Storage cut down factory temperature and eliminate false fire alarms

Automatic fire alarm systems help to keep premises and their occupants safe by providing an early warning of a possible fire, and enabling people inside the building to evacuate. However, a vast majority of signals from automatic fire alarms are not actual fires. Fire alarm and detection systems react to an increase in heat or the presence of smoke.

In January of 2015, Australia-based manufacturers and suppliers of commercial vehicle storage systems, Caddy Storage were faced with a similar situation. The company had installed an automated powder-coating line and an oven to increase its production output.

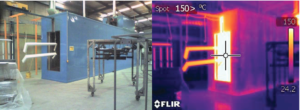

The 15-metre-long oven at the centre of the powder-coating line had two open-ended sides. The powder-coating line uses a programmed pretreatment and baking process in the oven. With all the heat escaping, there was a strong increase in temperature. Not only did this create an uncomfortable work environment but also increased the overall temperature of the building, resulting in false fire alarms during the summer. This resulted in fines from the fire brigade and loss of production time in the facility.

Temperatures of >150 C were recorded for the oven openings

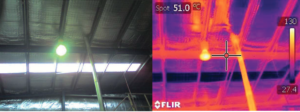

Temperatures of up to 51 C was recorded for the roof space, triggering false fire alarms

The excess oven heat was released to the surrounding area making the working environment unbearable with temperatures of up to 42.1 C

“The first time a fire alarm goes off, and if it’s an accident, you aren’t charged,” says Chris Brennan, Systems Manager and Chief Fire Warden at Caddy Storage’s Sydney facility. “But if there’s a subsequent false alarm within 60 days, you suffer the penalties. It can cost 1,500 Australian Dollars every time the fire brigade attends the call. By the time the firemen arrived, and we’d done a walk around to establish that everything was okay, and got everybody back to work, we’d lost about half an hour’s work per person. And when you’ve got to evacuate 90 people out to the emergency area, that’s about 45 hours of productive time lost. So we were losing a week’s wage every time there’s a false alarm.”

Thermal analysis highlighted that the existing louvres were not effective in removing the heat escaping from the oven. Temperatures of up to 51 degrees C were recorded at the roof space and 42 degrees C in the work areas.

In order to improve the ventilation and avoid paying fines to the fire brigade, Caddy Storage decided to install EcoPower EP900 hybrid ventilators from Edmonds. Being a hybrid ventilator, the EP900 is neither entirely natural nor entirely mechanical. When natural ventilation is not sufficient, its temperature sensors activate the ventilation system to ensure sufficient heat removal. Using real-time measured data, EcoPower shifts from natural ventilation mode to mechanical mode, ensuring that internal conditions are maintained continuously.

When outside temperatures and wind conditions permit, the turbines operate like a normal roof-mounted ventilator. If the difference between the external and internal temperature gets too low (reducing the effect of stack-driven ventilation), or the wind speed falls (reducing wind-induced ventilation), the EC motor in the EP900, mounted directly in the turbine, engages to boost airflow.

Ever since installing the turbines, the temperature in the workshop during summer has decreased by 10 degrees C, and no further false alarms have occurred due to overheating in the roof space. Caddy Storage claims that energy consumption has dropped significantly. In the mechanical mode, the units now typically consume between 180 W and 200 W per ventilator. EcoPower claims that the EC motor in EP900 allows variable-speed performance, with low noise and vibration transmission.

“It’s definitely more comfortable for workers,” Brennan says. “Ever since we have installed it, the fire alarms have stopped going off. We were running about five axial fans in our facilities, which are big, noisy, old and power-consuming creatures. The new systems are low noise, and the running cost and maintenance of them is negligible.”

Copyright © 2006-2025 - CPI Industry. All rights reserved.