Postulating the view that mechanical couplings offer alternative noise and vibration attenuation solution to traditional methods, Larry Thau demonstrates it with examples.

Postulating the view that mechanical couplings offer alternative noise and vibration attenuation solution to traditional methods, Larry Thau demonstrates it with examples.

Noise carried through piping systems is becoming an increasing challenge for owners, engineers and contractors alike. The reasons are varied, but include changing design requirements that place mechanical rooms on intermediate and top-floor building levels coupled with a greater use of lightweight construction materials that tend to vibrate more than traditional heavy materials.

In order to attenuate noise and vibration, designers often fall back on traditional attenuation methods for HVAC systems, as well as industrial utility piping. However, I believe that mechanical pipe joining systems offer advantages over traditional methods, and that this contention is supported by recent independent testing.

A sound idea

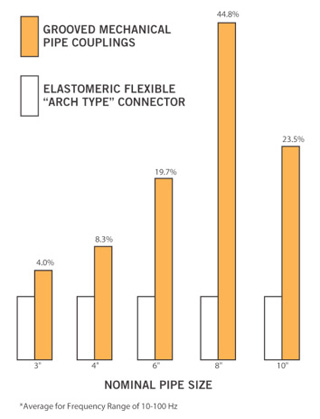

Designers have traditionally specified elastomeric flexible arch connectors to diminish noise and vibration from equipment connected to a circulation system. These connectors create a discontinuity in the metal piping (as opposed to welding), so that less vibration is transferred down the line.

Designers have traditionally specified elastomeric flexible arch connectors to diminish noise and vibration from equipment connected to a circulation system. These connectors create a discontinuity in the metal piping (as opposed to welding), so that less vibration is transferred down the line.

However, the weakness of flexible elastomeric arch connectors can result in premature rupture or leaks and expensive, lengthy installation times. Independent tests have shown that grooved couplings are as effective in sound and vibration attenuation as flexible arch connectors, within commonly experienced frequency ranges.

Recently, acoustical consulting firm, SSA Acoustics, in Seattle, Washington, undertook a field measurement which showed that three couplings, placed in close vicinity of the source have a comparable performance to twin-sphere neoprene connectors and a superior performance to braided metal hoses. These couplings dampened the overall vibration amplitude by 80% to 90%.

This supports previous testing from LS Goodfriend and Associates that has confirmed that a substantial vibration reduction is achieved in pipe systems that employ flexible couplings. Actual reduction measured in decibel level ranged from 2.3 dB to 12.1 dB over a wide frequency range.

Grooved couplings maintain excellent noise and vibration attenuation qualities, as well as the ability to accommodate deflection, expansion and contraction throughout the life of the piping system. Sound attenuation depends only on the three flexible couplings being placed near to one another, in close proximity to the source of vibration, so there are still numerous opportunities for design flexibility.

Good vibrations

Furthermore, each successive joint in a mechanical grooved system creates an additional reduction in vibration. Independent test laboratory, Nutech Testing Corporation/SE Laboratories used mechanical couplings in its testing, and concluded that, for any given pipe diameter, less vibration is transmitted with each additional coupling, whether flexible or rigid couplings are used.

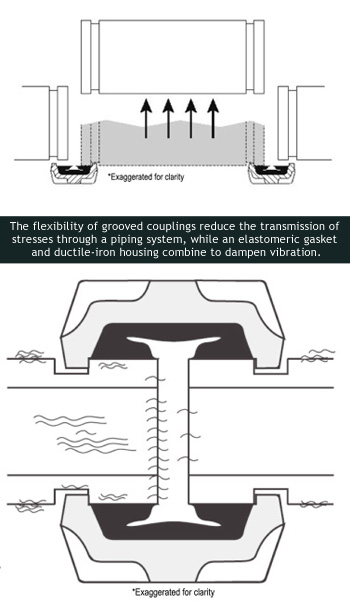

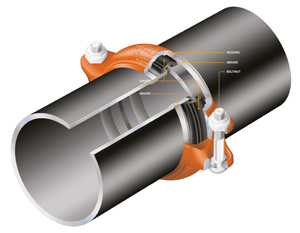

When explaining this reduction, it is necessary to examine the design of a coupling. The structure has a resilient elastomeric gasket contained inside the internal cavity of the ductile iron housing. This creates a discontinuity similar to that of a flex connector. The material from which the gasket is made also serves to absorb vibration.

When explaining this reduction, it is necessary to examine the design of a coupling. The structure has a resilient elastomeric gasket contained inside the internal cavity of the ductile iron housing. This creates a discontinuity similar to that of a flex connector. The material from which the gasket is made also serves to absorb vibration.

The key distinctions of a grooved pipe joint over a flex connector are inherent in the proprietary design of the coupling. Its unique construction enables the gasket to seal against the pipe, while the ductile iron housing provides both space for the elastomeric material to flex, and containment to prevent overstretching. Overall, the coupling works to create a permanent leak-tight seal with no need for additional reinforcement. Additionally, ductile iron has vibration dampening qualities of its own, so the external housing also serves to absorb sound.

The net effect can be viewed in this way: take continuous welded pipe to be the factor of one (all vibration is transferred without interruption). Install one grooved coupling, and the elastomeric gasket reduces noise transference and the ductile housing absorbs an additional amount of noise. That lowered vibration is then reduced by the same factor at the next joint. The same effect occurs again at each subsequent joint where a mechanical coupling is installed, providing a cumulative reduction in sound.

Couplings also offer the additional advantages of ease and speed of installation and maintenance, safety and reliability. This makes them an ideal replacement for traditional noise and vibration attenuation equipment in a number of different piping systems, and an alternative to welding or flanging.

Couplings are installed extensively in commercial buildings, such as stadiums and hotels, as well as industrial facilities. Regionally, these can be found in projects as diverse as the Alexandria Library and the Burj Khalifa.

Avoid rubber bellows and improve system reliability

In traditional mechanical room set-ups, rubber bellows or compensators are placed on either outlets of pumps to reduce noise and vibration. They are also sometimes used to correct misalignment between welded pipe and equipment, placing the rubber under undue stress. Rubber bellows require ongoing maintenance: as bolts gradually slacken and the system starts to weep, the bolts need to be tightened regularly. General wear and tear, along with exposure to UV light in the mechanical room, causes the rubber to perish.

In traditional mechanical room set-ups, rubber bellows or compensators are placed on either outlets of pumps to reduce noise and vibration. They are also sometimes used to correct misalignment between welded pipe and equipment, placing the rubber under undue stress. Rubber bellows require ongoing maintenance: as bolts gradually slacken and the system starts to weep, the bolts need to be tightened regularly. General wear and tear, along with exposure to UV light in the mechanical room, causes the rubber to perish.

With a best life expectancy of 10 years, rubber bellows will need to be replaced – perhaps several times within the life of the system, which involves system downtime plus the cost of a bespoke unit. Failure of the item can be sudden and unpredictable, causing serious health and safety risks if, for example, rubber splits in a heating system and hot water escapes.

Installing three flexible couplings on each side of a pump solves the problem. The method combines flexibility with durability to give superior noise and vibration attenuation without the need for costly, bulky flanged units. Guaranteed to last the life of the system, couplings provide a maintenance-free solution that delivers both practical and commercial benefits.

The writer is Vice President and Chief Technical Officer of pipe joining systems manufacturer Victaulic. He can be contacted at: LThau@victaulic.com

Copyright © 2006-2025 - CPI Industry. All rights reserved.