CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Highlighting that condensate from air conditioning systems is potential recoverable water, Farhan Juratli, in Part I of the two-part in-depth analysis on selection and maintenance of HVAC systems, dehumidification and condensate water recovery, focuses on design and selection of cooling coils.

Condensate from air conditioning systems should no longer be viewed as a waste product to be sent down sanitary sewer lines. Condensate recovery is especially applicable in facilities like shopping centres, where there is a high degree of air exchange. Bryant and Ahmed presented in 2008 a simplified model based on empirical data from a case study in Qatar, predicting condensate generation for a “normal” commercial air conditioning system to be eight gallons of condensate per tonne of cooling (8.6 L per KW of cooling) for each day, with a dew point (DP) temperature in excess of 60 degrees F (15.5 degrees C)[1].

EXAMPLE:

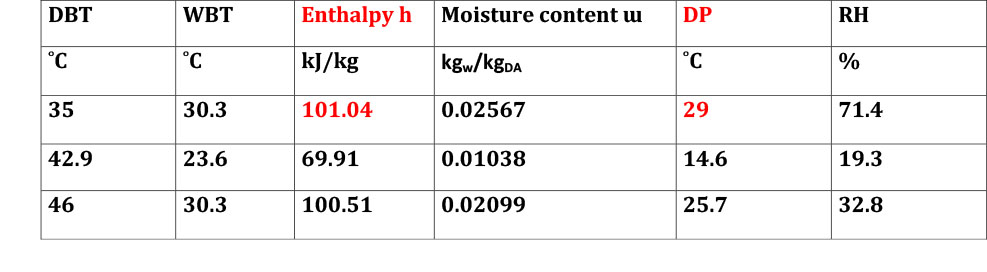

Air enters a cooling coil at Dubai’s design conditions: Dry Bulb Temperature DBT = 35 degrees C, and Wet Bulb Temperature WBT = 30.3 degrees C Ref. [2] at a rate of 100 cfm, and it leaves at DBT = 12.7 degrees C and WBT = 12.0 degrees C. Part of the moisture in the air that condenses during the process is also removed at the corresponding DP temperature. Determine the cooling capacity for the coil ??!”#. and moisture removal from the air:

SOLUTION:

Air is cooled and dehumidified by a cooling coil. The cooling capacity and moisture removal are to be determined.

ASSUMPTIONS:

1. This is a steady-flow process and, thus, the mass-flow rate of dry air remains constant during the entire process.

2. Dry air and water vapour are ideal gases.

3. The kinetic and potential energy changes are negligible.

PSYCHROMETRIC PROPERTIES:

The enthalpy of saturated liquid water (ℎ!) at 11.5 degrees C is the specific heat capacity of water 4.186 kJ/kg. degrees C × 11.5 degrees C = 48.14 kJ/kg

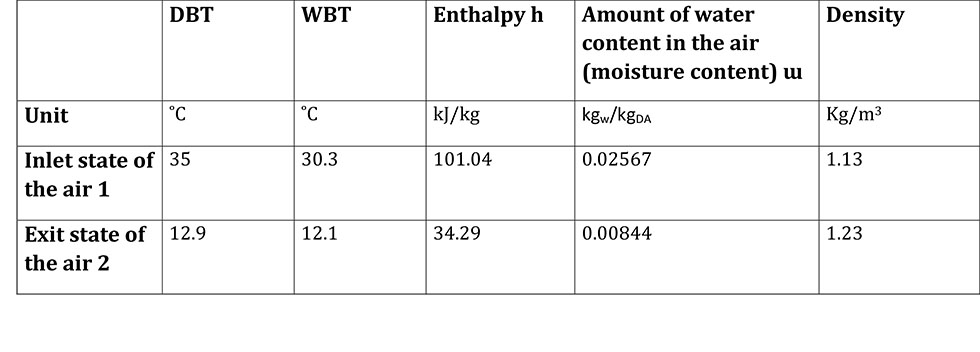

Also, the inlet and exit states of the air are completely specified. Therefore, we can determine the properties of the air at both states from the psychrometric chart, or Ref. [3] to be:

ANALYSIS:

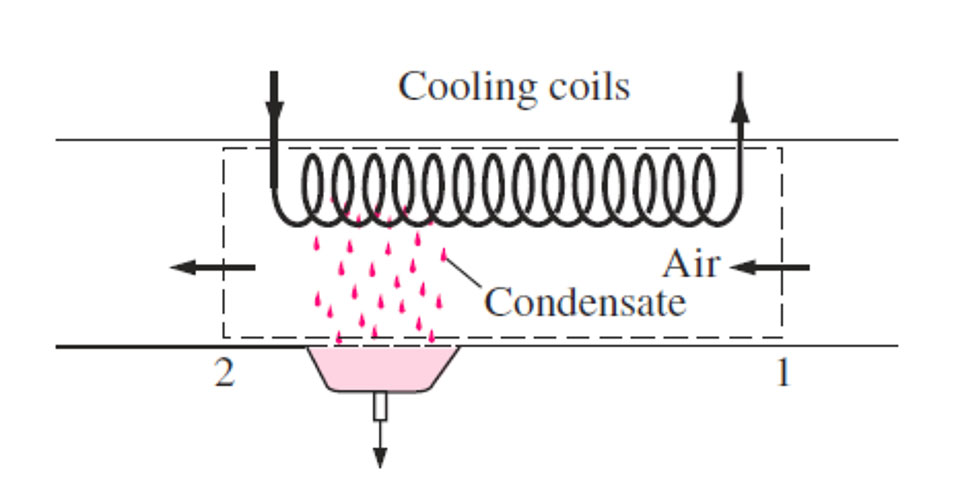

We take the cooling section to be the system. The schematic of the system is shown in the Figure (see left). Applying the mass and energy balances on the cooling and dehumidification section gives:

KEY POINTS

1. Don’t oversize the cooling load

The role of air conditioning in hot and humid conditions is twofold: Removing moisture from the air and reducing the temperature. Removing moisture from the air requires a far greater amount of energy than simply lowering the temperature. The oversized air conditioning units only run long enough to reduce the air temperature, and do not actually remove much moisture. This is because the compressor is automatically cycled off once set point temperature is achieved. The result is a lower indoor temperature, but actually a higher relative humidity or RH. (Colder air cannot hold as much moisture as warmer air.) To the occupants, this environment feels clammy or “cave-like” and uncomfortable, regardless of the space temperature.

It is often true that a space with slightly warmer temperature but lower RH is perceived to be more comfortable than one with a lower temperature but higher RH. Since cooling systems dehumidify the air only when the compressor is running (in DX and package units), it is very important to avoid oversizing equipment more than 20% to avoid excessive humidity at partial cooling load. Oversized systems spend too much time with the compressor cycled off to do a good job of dehumidifying the indoor air.

The ambient air temperature surrounding the body affects the heat gain or loss by contact (conduction) with the skin. The greater the temperature differences between the ambient air and the skin, the greater the rate of heat loss or gain. This heat gain is called sensible heat. The ambient air temperature is referred to as the dry bulb temperature. The RH, or the moisture content of the air, affects heat being dissipated by evaporation. The energy that changes the moisture from a liquid to a vapour is called latent heat. Air motion affects both the evaporation rate and the heat dissipated

by air motion (convection) and contributes to an individual’s sense of comfort. Moisture in the form of perspiration is given off through the pores of our skin. As this moisture evaporates, it turns into invisible water vapour. Evaporation is an important means for keeping us cool. The more humid the air, the slower the evaporation will progress. The less humid the air, more rapidly evaporation will progress.

The perceived air temperatures increase dramatically with increasing RH. For instance, an actual temperature of 34 degrees C feels like 48 degrees C at 70% RH, and feels like 57 degrees C at 85% RH! Ref [4].

2. Design for DP control instead of RH control: Keep the indoor temperature above 23 degrees C and below 26 degrees C, while also keeping the indoor DP below 12.0 degrees C. Keeping the DP low helps avoid the need to overcool the space, providing comfort for a wider variety of occupants.

DP is a measure of the absolute amount of moisture in the air, regardless of temperature. It is called dew point because the value actually predicts at what temperature moisture will condense on a surface. It is an excellent method of controlling humidity because, unlike RH that varies with temperature, DP provides an indication of moisture or the latent energy content in the air, and will remain constant, regardless of temperature. The ability to accurately measure moisture levels is important for reasons of the occupant’s health, the building’s structural integrity and building energy use.

When the indoor DP is kept below 12.0 degrees C, the cooling coil will cool the return air more quickly than if it had to first condense large amounts of moisture out of that air. So the time needed to cool the building down to the thermostat set point is reduced. The system responds more quickly to increased sensible heat loads, and more quickly to changes in the thermostat’s set point.

Earlier, it was difficult and expensive to use the DP to control the dehumidification components. Now, however, there is a wide variety of instruments and controls, which measure, display and control based on the DP. Owing to the evolution of more powerful microprocessor technology, it is possible to accurately calculate the DP on board a wall or duct-mounted sensor with increased accuracy. This capability is available for just a small additional cost over a standard temperature and humidity sensor.

This type of sensor is ideal for providing feedback for better moisture control inside buildings. In fact, any building automation system can easily convert the signals of air temperature and RH to a DP value, which can then be used to control the dehumidification equipment.

In most buildings, there is really no need to control the system based on RH, especially since there are so many benefits to controlling the system based on the air’s DP. First among the benefits is that the DP is an indicator of current risk to the building. When you know the air’s DP, you also know what surface temperature will condense moisture from that air. So you will quickly realise, for example, that when the DP is 18.3 degrees C and the supply air is 13.0 degrees C, the outside of a steel duct which carries the cold air will sweat (condense large amounts of moisture). Condensation and moisture absorption lead to mould growth and corrosion, which cause damage to buildings.

The RH of the air does not give you that same useful information. The RH at the sensor is not the same as the RH at the cool surfaces of ducts, pipes and walls washed by cold air. The DP tends to be nearly the same throughout the building.

We all know that temperature-controlled air conditioning systems are running less and saving lots of energy. However, while the sensible load has been reduced, moisture sources primarily related to people breathing/activities and outside air infiltration that can introduce humid air, have basically remained the same. This has created a problem, where air conditioning is running long enough to control temperature, but in many cases, it does not run long enough anymore to remove moisture from the air. In a research study sponsored by ASHRAE, it has been determined that if an air conditioner runs for 15 minutes or less, moisture will condense on the coil but will not get to the point where it drains off. When the air conditioner turns off, but air is still blowing through the coil, the moisture evaporates back into the space. This could happen regularly if the system is oversized or if it is operating under part-load conditions.

There are plenty of control strategies and equipment that can remove moisture from the air, but accurate measurement of DP levels is the only effective way to control the amount of moisture in the air. Recent breakthroughs in affordable DP measurement mean, we have a better tool for controlling all aspects of building operation, from cooling to economiser control to dehumidification control.

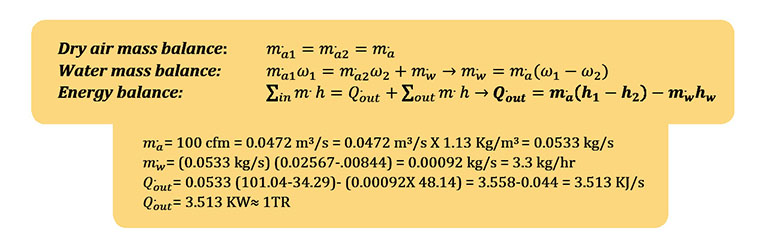

3. It is important to note for Dubai’s design conditions that the enthalpy (heat content or total heat) at peak dehumidification load DBT/WBT = 35/30.3 is 31% higher compared to the enthalpy at design peak cooling condition DBT/WBT = 42.9/23.6. The total heat at the peak dehumidification load above is even a bit higher than the total heat corresponding to non-coincident DBT/WBT = 46/30.3, as illustrated in the table below:

The table, below, reflects that peak dehumidification loads occur when the outdoor DP is at its highest point for the year, not when the outdoor dry bulb temperature is at its peak.

References:

1. Bryant, J.A., T. Ahmed. 2008. “Condensate water collection for an institutional building in Doha, Qatar: an opportunity for water sustainability.” Proceedings of the Sixteenth Symposium on Improving Building Systems in Hot and Humid Climates.

2. 2013 ASHRAE Handbook – Fundamentals

3. http://daytonashrae.org/psychrometrics_si.html

4. https://en.wikipedia.org/wiki/Heat_index

____________________________________________________________

Farhan Juratli is LEED AP and Certified Energy Manager (CEM) with over 20 years of experience in the design, commissioning, retro-commissioning, evaluation and optimisation of HVAC systems for commercial and residential buildings. He was a lecturer in Thermodynamics and Heat Transfer at the American University of Sharjah in 1999 and Operation Manager at Carrier Corporation. He is currently a Project Manager – District Cooling. He can be contacted at juratli@hotmail.com

_____________________________________________________________

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Copyright © 2006-2025 - CPI Industry. All rights reserved.