In this article, Tawfiq Attari addresses condensation concerns in fabric ducting applications.

In this article, Tawfiq Attari addresses condensation concerns in fabric ducting applications.

Theory

When specifying a duct system design, an important consideration is the potential of condensation on the exterior surfaces. As metal duct is most commonly used, single wall metal duct is applied where condensation is not an issue, and double wall or insulated metal duct would be used to prevent condensation or heat gain/loss. Designers of fabric duct systems also have options to control gathering of moisture and condensation on the outer walls of the ducts.

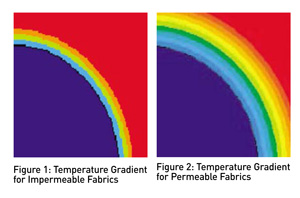

Common fabrics are available in permeable or impermeable constructions. Impermeable fabrics typically are either manufactured as a solid film material or a woven construction with a coating on one or both sides. While the coating offers fabric stability for cutting and construction, it yields a defined barrier offering little thermal benefit. The temperature gradient from duct surface to room air is due to natural convection, therefore very narrow, as shown in Figure 1.

Permeable fabrics are generally a woven construction and are processed to a specific permeability (should not be less than 1 CFM/Sq feet at 0.5”WG static pressure). In theory, conditioned air passes through the fabric and creates a thin layer around the duct wall of tempered air. This boundary prevents the warm, moist room air from contacting the duct wall and generating condensate. With this concept in mind, the permeable fabric ducts can be considered a direct alternative to insulated or double wall metal ducts. Figure 2 reveals the expanded gradient for the permeable fabrics due to controlled outward airflow.

Permeable fabrics are generally a woven construction and are processed to a specific permeability (should not be less than 1 CFM/Sq feet at 0.5”WG static pressure). In theory, conditioned air passes through the fabric and creates a thin layer around the duct wall of tempered air. This boundary prevents the warm, moist room air from contacting the duct wall and generating condensate. With this concept in mind, the permeable fabric ducts can be considered a direct alternative to insulated or double wall metal ducts. Figure 2 reveals the expanded gradient for the permeable fabrics due to controlled outward airflow.

Test results from a fabric duct manufacturer in USA in collaboration with BESS Lab, showed a significant reduction in condensation on permeable fabrics at 95% relative humidity.

These consistent test conditions and various evaluations clearly identify concerns of condensation for impermeable materials (metal or impermeable fabrics). Fabric permeability rate has little effect – as tests results are similar between 1 cfm/ft2 and 2 & 6 cfm/ft2 fabrics.

Conclusion:

For applications in which condensation is a concern, permeable fabrics yield the lowest possibility for condensation and show no condensation at 80% RH.

It also shows no condensation in the indoor swimming pool application.

Therefore, given that comfortable RH for people is around 50%, fabric duct can be used in any application without any fear of condensation.

The author is Global Sales and Technical Director MENA at DuctSox. He can be contacted at tawfiq@ ductsox-mena.com.

Copyright © 2006-2025 - CPI Industry. All rights reserved.