Rehan Shahid says that while harvesting condensate water for flushing toilets is not new, the ability to do so with ease, and without deploying massive apparatus or undertaking costly and disruptive renovation work is uncommon

Air conditioning units produce condensate water as part of the cooling process. A cooling coil in the air conditioner cools and dehumidifies the air in the room by pulling in and removing condensation from the air before replacing it with dry, cooler air. Most of the condensation from the cooling coil falls into the drain pan, and the quality of this water is essentially the same as distilled water.

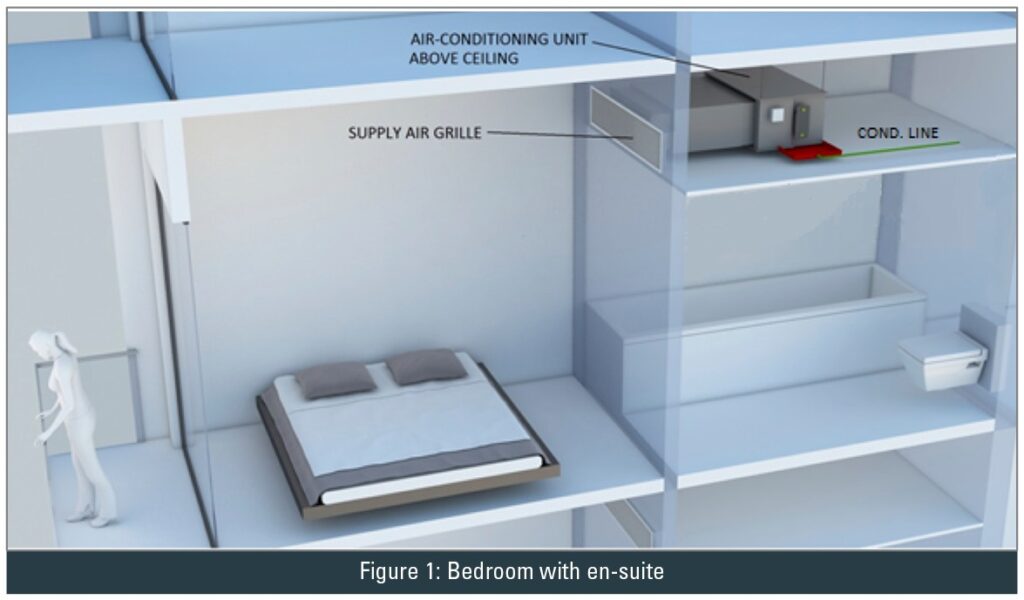

In the case of residential buildings, all the condensate from the air-conditioning unit(s), which is often located above the ceiling in wet areas (Figure 1), is usually piped to the nearest floor drain.

To date, there have been many advancements and techniques used to collect the water and reuse it for flushing, irrigation and as make-up water for cooling towers.

In this article, we will focus on using the water directly for toilet flushing without adding massive apparatus, as opposed to other methods that have been addressed many times in various studies.

Using condensate from air conditioning units directly usually demands changes to the water closet; therefore, the type of water closet (WC) that may be used needs to be considered well in advance, if it is a new construction, or if a renovation project.

There are various types of toilet cisterns now available that can accommodate additional volume as well as parts that may be required in order for it to store and use the condensate water for flushing (see Figure 2). This, along with dual-flush mechanism, makes these options green but rather big and a little expensive.

For existing buildings, if such installation is at the expense of changing the entire bathroom suite then this may not be a desirable option. Surely, there must be another solution, a relatively simple system that could be employed to use condensate water for flushing with little modification – one that will not cost a lot and would work with the existing toilet cistern.

One such solution is discussed below, based on a practical test installation.

The volume of condensate produced varies depending on the capacity of the

air conditioner and the outdoor humidity level. It is suggested that most modern air conditioners will produce between 19 and 76 litres of condensate per day.[1, 2]

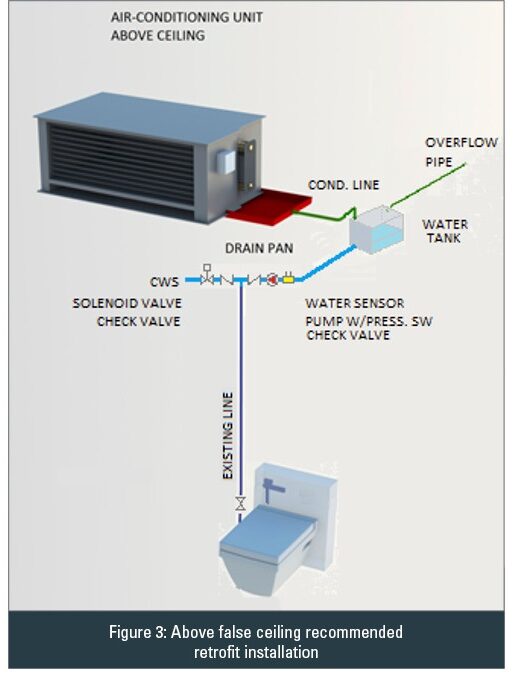

Using a simple system, as shown in the design solution (Figure 3 and Figure 4), it was realised that it is possible to collect up to 15 litres of water in a day from an air-conditioning unit (12 hours running time) of around 5.3 kW (11⁄2 TR – high- ambient temperature) cooling capacity. This water would then be used to fill the toilet cistern, and any top-up, if required, will be supplemented by the CWS from the mains.

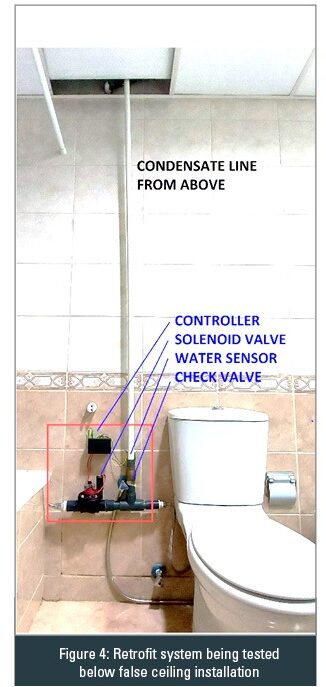

Figure 4 shows the installed retrofit solution being tested at a residential unit in Dubai. A 9V DC solenoid valve was used for this exercise, and exposed arrangement was considered only for the testing purpose.

The design solution, depicted above, does not demand any major changes to the existing water closet. All that would be needed are a few inexpensive check valves, a solenoid valve, a water sensor, some associated electrical works and a small water storage tank (12-18 litres). These are added to a line from the condensate drainpipe and connected to the cold water supply (CWS) pipe, supplying the WC. The assembly, being compact, can usually be installed easily in the space above the false ceiling, closer to the indoor unit, as illustrated in the sketch (Figure 3).

A mini (booster) pump may be required if the toilet cistern fill (inlet) valve minimum working pressure is more than the available static head. The other less favourable option that may be considered is to replace the fill valve with one having low working pressure (i.e. 0.01MPa).

The working principal is straightforward; the water sensor keeps the solenoid valve closed as long as there is water in the condensate tank; this stops the water flow from the CWS line. Following a flush, the water stored in the water tank flows first through the existing supply line (see Figure 3) into the toilet cistern. The solenoid valve opens only when the condensate tank is empty, and lets the mains water flow into the cistern, if required; a simple controller is used to carry out this operation. Check valves are installed so that mains water does not flow into the condensate line or tank, and vice versa.

For this retrofit solution executed in Dubai, the payback is estimated to be in two years, depending on the AC running hours and WC usage. And for new builds, as the cost of installation would be much lower, an even shorter payback period can be expected. Considering the cost of the system is in hundreds and not thousands, it may be regarded as an inexpensive option.

SO, HOW MUCH WATER MIGHT BE SAVED?

For example, let us consider a two-bedroom apartment having two bathrooms and AC indoor-units with a total cooling capacity of 21.1 kW (6 TR – high- ambient temperature). With a production rate of up to 0.3 gallons per hour of condensate per ton of air conditioning [4], depending on the geographical location, number of hours of AC operation and WC usage, a possible water savings of between 29,844 litres (7,884 USG) and 59,688 litres (15,768 USG) per year could be realised.

It may not seem a large enough volume, but considering there are thousands of existing residential units, hotel apartments and offices, and new ones being constructed every year, the water savings would be significant.

WHERE CAN WE USE THE SYSTEM?

As mentioned earlier, the system can be used for various types of new and existing buildings, such as villas, townhouses, and hotel and motel guest rooms having en-suite bathrooms.

It may also be used for buildings for which having an on-site central condensate recovery and distribution system is not economically feasible. Currently, the condensate from the air-conditioning units for such buildings is discharged straight into the drain.

The design solution detailed here costs truly little, is compact, uses materials and components that are readily available in the market and, therefore, can easily be employed. And the water savings that will be realised makes it worthy of consideration, especially for hot and humid regions.

In regions where water is scarce, I am sure all would agree that every bit helps.

References:

1) https://airexpertsnj.com/knowledge/entry/ how-much-water-should-drain-from-your- ac-a-nj-tech-explains

2) https://www.hunker.com/12575176/how-much-water-should-drain-from-a-central-air-conditioner

3) http://www.encorecistern.com/

4) Condensate water recovery, ASHRAE Journal (2005)

Rehan Shahid is Director, P&T Architects & Engineers. He may be contacted at rehan@ptdubai.ae.

Rehan Shahid is Director, P&T Architects & Engineers. He may be contacted at rehan@ptdubai.ae.

#HVAC #HVACR #ASHRAE #water #wateroptimisation #wateroptimization #watersavings #airconditioning #buildingperformance #IAQ #IEQ #airquality #indoorairquality #airconditioning #airconditioningmiddleeast #airconditioningUAE #HVACDubai #HVACRDubai #HVACUAE #HVACRUAE #condensate #condensaterecovery #MEP #plumbing #retrofit #buildingretrofit #renovation #buildingrenovation #pump #pumps #valve #valves #solenoidvalve #solenoidvalves #statichead #watersensor #watersensors #checkvalve #checkvalves

Copyright © 2006-2025 - CPI Industry. All rights reserved.