A system where air travelling within concrete slabs, utilising concrete’s thermal mass to reduce the installed cooling and heating capacity by up to 50%, reducing power consumption by 25-35%+, and reducing HVAC-related operations and maintenance by >50% is the way to go, says Ghassan Nimry, especially when the clamour for more fresh air changes is tempered by efforts to lower indirect emissions and total cost of ownership

Construction is undergoing a forced stoppage, worldwide. Limited access to sites, stricter control of workers working on projects, social distancing, uncertain delays in procurement and a general economic downturn, worldwide is holding back projects everywhere.

This hiatus is the perfect opportunity to rethink old practices and employ new and creative ways to improve how we build so that we can live better and healthier. Social distancing is one simple yet effective technique to keep us removed from catching viruses that circulate in the air around us. Yet, when indoors, we may keep our physical social distance, but the air we breathe has been circulating in far larger spaces and with other people, and can transmit all kinds of particles, including pathogens, negating all our best efforts at minimising exposure to microbes.

As we have seen with the COVID-19 virus (SARS-CoV-2), opportunistic pathogens – bacteria, viruses, fungi, etc. – are becoming more prevalent and their impact is global. This is exacerbated by our modern buildings and HVAC systems, many of which rely on recirculating cooled or heated air inside the building, and on a significant amount of HVAC equipment installed internally, usually behind false ceilings. These air ducts and fan-coil units create an ideal environment for the pathogens to thrive and spread.

Airborne pathogens – for example, bacteria, viruses, mold spores and fungi – circulating in homes and buildings can cause discomfort in a healthy person, such as Sick Building Syndrome, and may cause severe health issues for people with weakened or compromised immune systems. We are susceptible to these pathogens potentially reaching us from other people in the constantly recirculating air flow from the HVAC. Further, these pathogens can also thrive in air supply ducts or HVAC drainage trays, and are released into the airstream when the HVAC system is turned on. Both these factors add to our health risks.

Conventional air conditioning in many climates has a few basic health shortcomings:

It is important to understand how this works: The nasal passages’ walls are coated with millions of tiny hair-like structures that form part of the respiratory mucus membranes. Their main function is to trap any incoming dust, bacteria, mold, viruses, etc., in the mucus and transport them to the back of the throat to be swallowed, where the stomach’s highly acidic gastric juices (pH 2-3) can neutralise them.

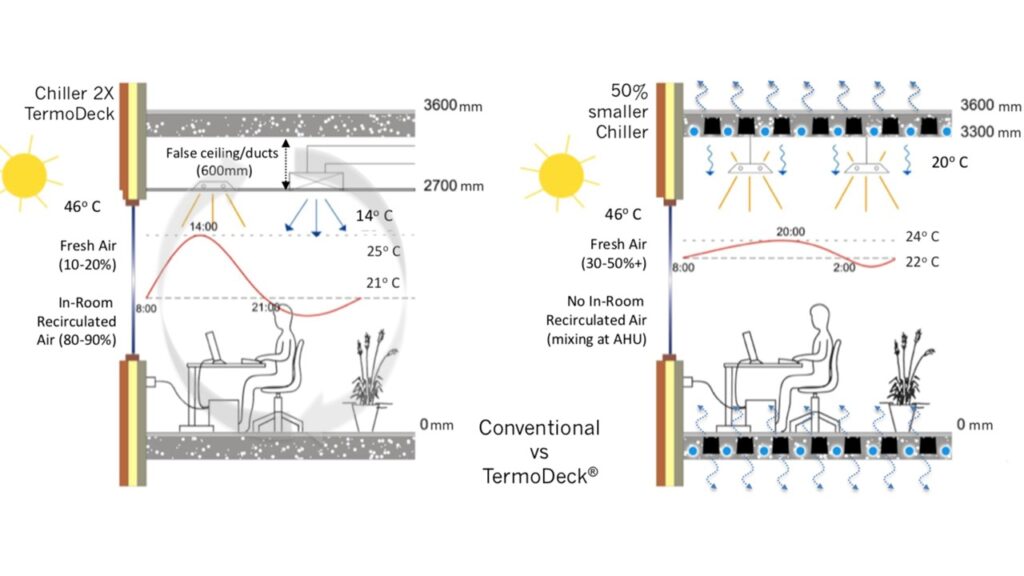

An overly dry internal environment – whether cold or hot and typical of conventional HVAC – can lead to the drying out of the mucus membranes, rendering ineffective the ability of the body to trap airborne pathogens and send them to the stomach. This allows these pathogens to reach deeper into the respiratory system, possibly leading to upper respiratory infections (sinus and throat infections), and in more serious cases, lower respiratory infections (bronchioles and lungs). The body is very effective in fighting infections, but chronic exposure to such an environment – for example, the ones we are exposed to in homes and work spaces using conventional heating and cooling – can overwhelm our defences and can cause many uncomfortable symptoms, including sinus pressure, headaches, sore throats, nosebleeds and dry mouth/nose. About 40 years ago emerged an HVAC system that circulates air within concrete slabs, utilising concrete’s thermal mass to reduce the installed cooling and heating capacity by up to 50%, reducing power consumption by 25-35%+, and reducing HVAC-related operations and maintenance by >50%, thereby slashing the building’s carbon footprint while cutting capex and opex. The system has been applied successfully in numerous projects, worldwide, including residential, commercial, educational, retail and healthcare-related buildings in Europe, Middle East, Africa, North America and Australia.

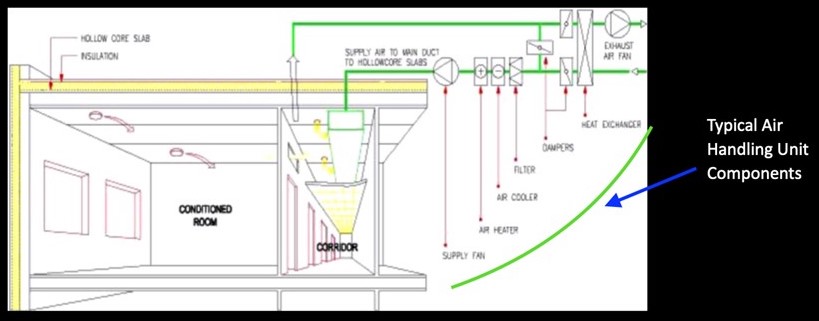

Air passes through supply ducts into the concrete slabs and, then, from the slabs into the occupied spaces, taking advantage of the concrete’s thermal mass, which reduces the installed heating/cooling capacity by up to ~50%.

In addition to these impressive sustainability features, several key features of the system also provide for a superior indoor environment:

1) The system provides a higher fresh air component compared to conventional HVAC

2) It does not rely on recirculating the same air inside each space but rather takes all the internal air out of these spaces to the air-handling units (AHUs), where fresh air is introduced and where all the air volume is properly filtered/treated and then brought back into the occupied spaces

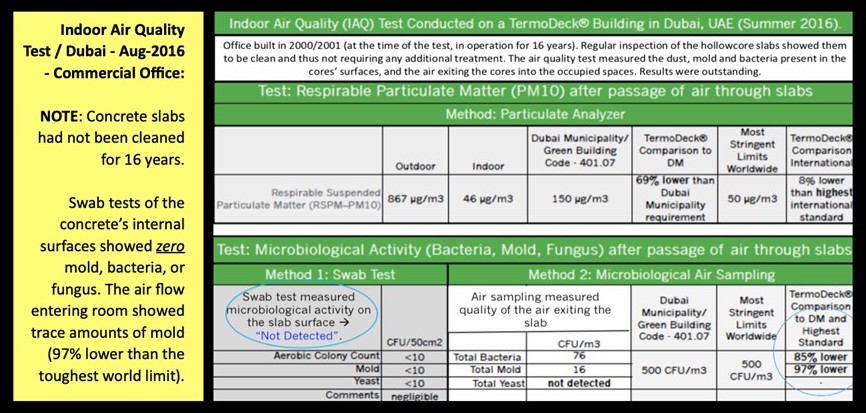

3) It does not promote any bacteriological growth due to concrete’s high pH levels (12.5-13)

4) Internal temperatures are maintained within a narrow/comfortable range 24/7, 365 days/year

5) It localises all HVAC equipment externally – that is, roof/basement – and so does not require any equipment internally, eliminating a primary source for bacteriological growth

6) With external equipment, no HVAC-related maintenance is required within the occupied spaces.

In addition to the ability to reduce the installed cooling/heating capacities by up to ~50% and using 25-35% less power, the system’s core design principles directly create healthier indoor environments and are not simply an afterthought. With the system in place, the HVAC system in the building runs silently; provides consistently draught-free comfortable temperatures, 24/7, all year round. As a combined radiant and convective HVAC system, it is not only more comfortable – the supply air temperature is only a few degrees higher than the room temperature – but it also reduces the overall air volumes, providing a far higher proportion of fresh air. The system further eliminates recirculation of air within each space. All the internal air is removed from the rooms and sent to the air-handling unit (AHU), where a significant proportion is exhausted, fresh air brought in, filtered, treated and conditioned before being sent back into the occupied spaces.

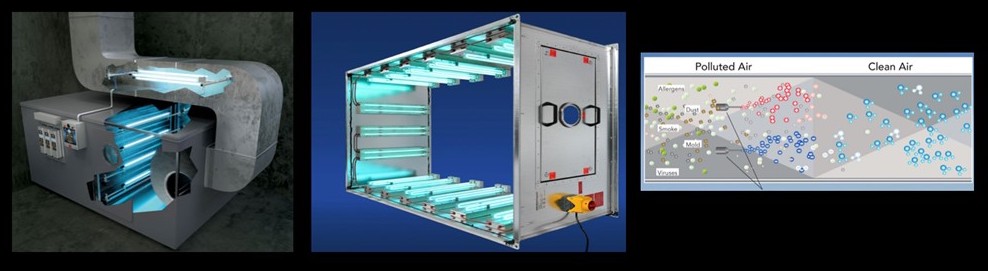

It is at the AHU that all the pathogens can be removed by filtration and sterilisation. Filtration – including HEPA (High Efficiency Particulate Air) filters – helps purify the incoming air. HEPA filters are designed to capture 99.97% of particles of 0.3 microns or larger. This is enough to capture most pathogens. However, Coronavirus – for example – ranges from 0.06 to 0.14 microns, so some will pass through even a HEPA filter. As an additional level of protection, UV-C steriliser (UV germicidal irradiation) or ionisation modules can be added to the AHU, which will neutralise all viruses in the air-path by destroying its ability to replicate. Such modules can also be placed in the main supply ducts, ensuring almost total sterilisation of the entire air volume.

Whereas in many HVAC systems, 80-90%+ of the air recirculates internally, the system I am talking about compels the entire volume of air to exit the occupied spaces and pass through the AHU, allowing the continuous filtration/sterilisation of the entire air volume, ensuring near-zero pathogens in the building’s supply air. This is an unprecedented ability for an HVAC system to simultaneously achieve this level of indoor air quality (IAQ) in an environmentally friendly building that uses about half of the cooling/heating capacity of a conventional HVAC building.

These capabilities of the system were recognised by the multiple awards received internationally. Its impact goes beyond energy and into cost, occupant comfort and the environment.

In the above school project, the installed system redesigned the HVAC to reduce the installed AC capacity by 58%, reducing the connected electrical load by ~33%, while allowing for ~50% fresh air (instead of the usual 15-20%). If we converted the school to 100% fresh air, the system would require ~29 m2/TR of cooling capacity, compared to ~10 m2/TR, if using conventional AC. Put another way, for 100% fresh air, each ton AC would only cool 10 m2 with conventional AC but would cool 29 m2 with the system in place (three times as much space). The system’s health benefits are evident in all our projects, but one particular project stands out: The Maun District Hospital for Highly Infectious Diseases, in Botswana, in southern Africa), below, where the very nature of the patients being treated (highly compromised/weakened immunities) and illnesses treated (for example, HIV/AIDS) necessitated a solution that increases the chances of recovery and reduces the chance of cross infections within the hospital. The system was able to do just that. The system has been recognised by the UK government as “mercifully bulletproof”. It is flexible enough to work with almost any commercially available HVAC equipment, and can adapt to greener forms of concrete and 3D-printed structures, as these become more commonplace.

The system can also be used in conjunction with solar energy – PV panels and CSP – that is, in harmony with other energy-saving technologies and natural energy systems. This can help relieve pressure on municipal power supplies and budgets, and also increase livability by improving IAQ and minimising the detrimental effects on outdoor air quality (OAQ).

Social distancing is the most effective way of preventing the spread of COVID-19. Rather than recirculating air internally, the system sends the entire air volume to the AHU (no internal air recirculation). This enables a “social distancing” solution for internal building air, sending it away from the people who share the same airspace, providing fresh air indoors, reducing the spread of viruses, sustainably.

As the world prepares for the post-Coronavirus/COVID-19 phase, and as the awareness of the importance of maintaining a healthy living environment takes the importance it deserves, the installed HVAC system is probably the one way for building owners and occupants to be fully confident that they are not only living and working in a place that is free from pathogens in the HVAC system but also in a building that requires ~50% of the installed heating and cooling capacity and consumes 25-35% less power (compared to conventional AC), and costs less to build, operate and maintain.

The writer is Director, Eco-Structures International Limited. He may be reached at gnimry@eco-structures.net

#hollowcore #thermalmass #concrete #concreteblocks #cooling #heating #power #energy #energyconsumption #energyefficiency #climatechange #climatecrisis #climatechangemitigation #HVAC #HVACR #sustainable #sustainabledevelopment #sustainability #freshairchanges #ACH #IAQ #IEQ #indoorairquality #pandemic #SARS-CoV-19 #COVID #Covid #COVID-19 #Covid-19 #coronavirus #novelcoronavirus #virus #pathogens #microbes #fancoilunits #FCUs #AHUs #airhandlingunits #SBS #sickbuildingsyndrome #mould #airquality #carbonfootprint #respiratory #airfiltration #filtration #airfilters #HEPAfilters

Copyright © 2006-2025 - CPI Industry. All rights reserved.