Variable speed drives reduce energy consumption and increase system efficiency in refrigeration applications, says Abdelhak Dhab, and backs it with empirical evidence.

Variable speed drives reduce energy consumption and increase system efficiency in refrigeration applications, says Abdelhak Dhab, and backs it with empirical evidence.

Abstract

This article will discuss the advantage of using frequency converter technology in refrigeration applications to control compressors.

This article will discuss the advantage of using frequency converter technology in refrigeration applications to control compressors.

As shown through theory and case study, speed control of refrigeration components provides maximum flexibility, control and energy efficiency. Most refrigeration systems spend most of their operating hours at reduced capacity.

Screw compressors back off slide valves, reciprocating solenoid valve capacity control and other compressor types use on/off. Unfortunately, these control methods do not provide the maximum attainable reduction in brake horsepower as the refrigerant capacity is reduced.

Frequency converter control

In standard system design, electric motors are intended to operate at a fixed speed. This speed is determined by the frequency of power supplied by the utility and motor design (number of poles).

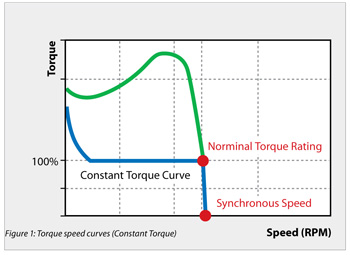

The shaft load on the motor is determined by the product of shaft speed and torque. With a fixed speed, motor power is determined by the torque of the load. With a change in speed, motor load will not only benefit from the speed reduction but also any reduction in torque with speed. Two types of motor loads exist: Constant torque and variable torque.

The shaft load on the motor is determined by the product of shaft speed and torque. With a fixed speed, motor power is determined by the torque of the load. With a change in speed, motor load will not only benefit from the speed reduction but also any reduction in torque with speed. Two types of motor loads exist: Constant torque and variable torque.

Positive displacement compressors such as screw, reciprocating and rotary vane are constant torque devices. That is, the twisting force required to turn the shaft is constant, regardless of speed. Therefore, the shaft power is determined by operating conditions (pressures) and method of capacity control, which both effect torque. In general, a reduction in 50% speed would provide a proportional 50% reduction in shaft power. (See Figure 1).

General drive control

Using frequency converters to control cold storage capacity provide improved control and efficiency, whether for compressors, fans or pumps. There are several incentives for using speed control on screw compressors. They are:

Using frequency converters to control cold storage capacity provide improved control and efficiency, whether for compressors, fans or pumps. There are several incentives for using speed control on screw compressors. They are:

Drive operation of screw compressor

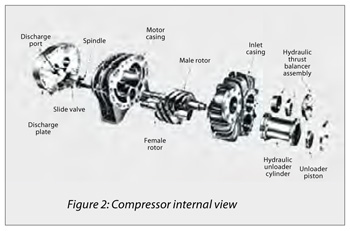

Almost every rotary screw compressor uses a slide valve for unloading. The slide valve moves along the length of the rotors, reducing the compression length within the rotors. An internal view of a screw compressor is shown in Figure 2.

Although this control method is infinitely adjustable and provides reasonable suction pressure control, there can be a substantial power penalty associated with slide valve control.

Although this control method is infinitely adjustable and provides reasonable suction pressure control, there can be a substantial power penalty associated with slide valve control.

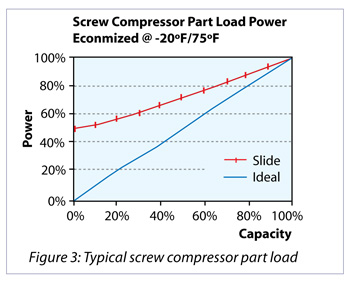

As the compressor unloads, there is no proportional reduction in power. A typical screw compressor part load curve is shown in Figure 3.

In general, part-load performance degrades with deeper suction or higher discharge pressure. Also, economised compressors typically lose economiser operation at approximately 75% slide position. Below this position, the compressor operation is non-economised.

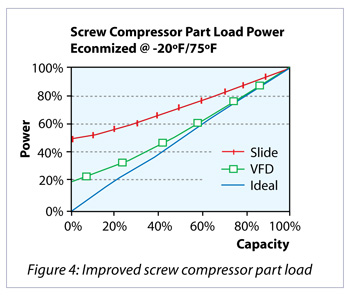

Most screw compressors can operate down to 50% speed, as rated by the factory. Below 50% speed, the slide valve must be used for further capacity reduction. The improved part-load power curve is shown in Figure 4.

Most screw compressors can operate down to 50% speed, as rated by the factory. Below 50% speed, the slide valve must be used for further capacity reduction. The improved part-load power curve is shown in Figure 4.

Note the substantial improvement in compressor performance throughout the entire range of loads. A compressor drive is shown in Figure 5.

Figure 6 shows the compressor pack with a master drive connected in parallel with several fixed speed compressors.

Figure 6 shows the compressor pack with a master drive connected in parallel with several fixed speed compressors.

The concept is based on intelligent VLT frequency converters. These frequency converter types can handle the open-loop and close loop control tasks in the compressor pack. The main function of intelligent frequency converters is to maintain the suction pressure constant by continually adapting the speed of the variable speed compressor.

The benefit of using cascade control compressors is to reduce the size and the cost and to keep the same or better capacity.

The benefit of using cascade control compressors is to reduce the size and the cost and to keep the same or better capacity.

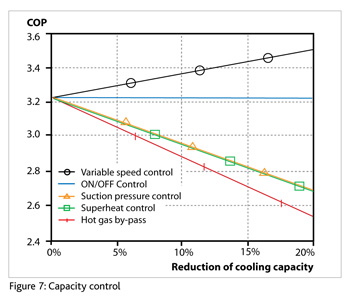

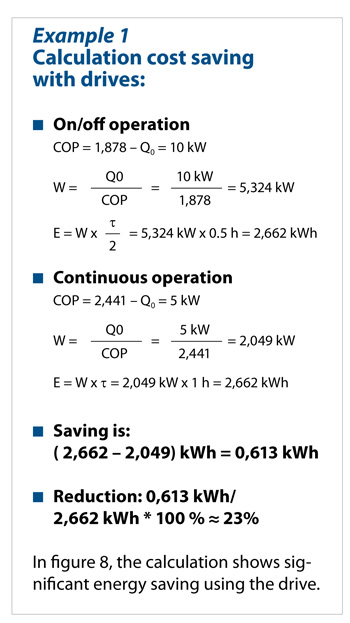

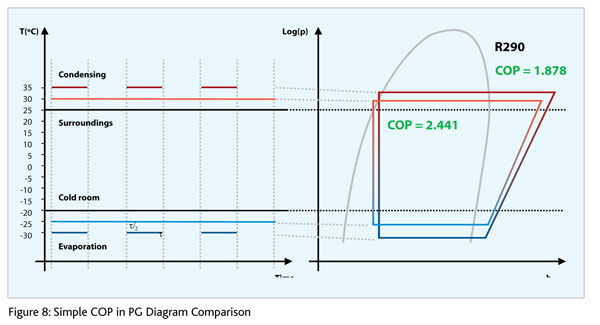

To use drives to control speed increases the COP (coefficient of performance) of the system and reduces the energy consumption. The comparison is shown in Figure 7.

In Figure 8, the calculation shows significant energy saving using the drive.

Screw compressors used in refrigeration plants come in two types:

a) With slide valve for capacity modulation

b) Without any capacity control regime

Although the slide valve control gives reasonable suction pressure control, there is a certain energy consumption associated with the slide valve control.

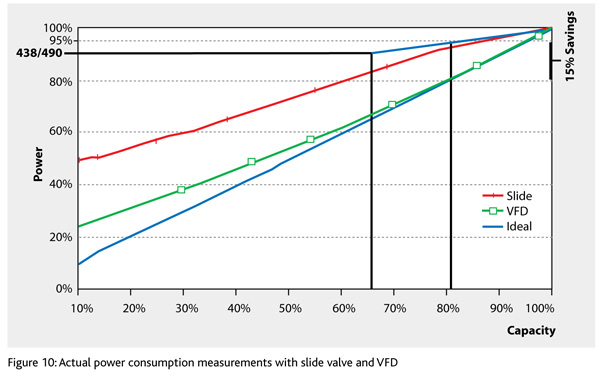

From the power consumption chart (Figure 10) we can see that the slide valve method of control do not follow the capacity control. In the case of 60% capacity, the slide valve control consumes approximately 80% of the power. Whereas, with drive control, at 60% capacity, the power consumed is approximately 60%.

From the power consumption chart (Figure 10) we can see that the slide valve method of control do not follow the capacity control. In the case of 60% capacity, the slide valve control consumes approximately 80% of the power. Whereas, with drive control, at 60% capacity, the power consumed is approximately 60%.

Our experience with a customer in Canada with a screw compressor is that we obtained the following results:

Compressor motor data:

(*based on actual measurements)

Assuming average annual capacity is 80% of the installed capacity, 20 hours working per day and 365 days operation, the comparison of slide valve versus drive control is given below:

With slide valve:

267 kW x 365 x 20 = 19,49,100 units

With drive control:

Energy consumption is 15% lower = 16,56,735 units

Savings: 2,92,365 units

Cost savings (@ Rs 5 per unit) = Rs 14,61,825

Average installed cost a 315 kW VFD = Rs 14,00,000

Payback period = 1 year

The writer is Global Business Development Manager, Refrigeration Business, Danfoss VLT Drives.

Copyright © 2006-2025 - CPI Industry. All rights reserved.