With a case study as evidence, Arne Heuzeroth and Kazuhide Ishida argue that SAC is a sustainable alternative, as solar thermal absorption chillers improve energy efficiency of compression cooling plants.

With a case study as evidence, Arne Heuzeroth and Kazuhide Ishida argue that SAC is a sustainable alternative, as solar thermal absorption chillers improve energy efficiency of compression cooling plants.

ABSTRACT

The continuing rise of power demand in the GCC countries is a key challenge for further growth of the region. Since air conditioning accounts for approximately 70% of the region’s total power consumption,1 it is obvious that innovations towards more sustainable cooling technologies are paramount in order to reduce the strain on the region’s electrical grids and make more power available to business and industry. Solar Assisted Cooling (SAC), providing additional pre-cooling for chilled water or condensers of compression systems generated from small-scale solar thermal-driven absorption chillers, offers an interesting alternative to ease the power consumption of conventional cooling systems, while at the same time optimising the overall energy efficiency and reducing carbon footprint.

CONTEXT: POWER DEMAND AND CARBON EMISSIONS FROM AIR CONDITIONING IN THE GCC COUNTRIES

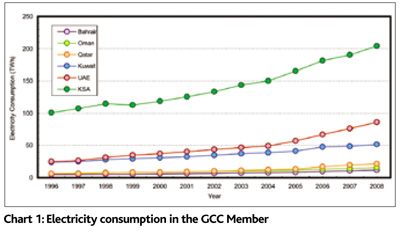

The electricity demand of the GCC member-states has significantly increased over the last decade (cf. chart 1). In some regions, this demand has already surpassed the existing power capacities during summer peak loads. Electricity consumption in peak season is approximately 35% higher than the annual average, and approximately 90% higher compared to consumption in winter. 2 This is mainly due to the rise in demand for electric chillers in peak season, which puts an extreme strain on the electricity grids. As the region continues to grow, the demand for power will further increase.

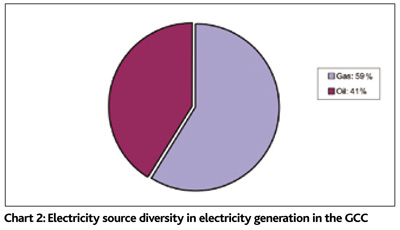

As a reflection of this, the total CO2 emission has also increased. The annual power consumption in the region is around 398TWh/annum, which equals to CO2 emissions of approximately 295 million metric tonnes per annum.3 This high value stems from the region’s energy mix, which focuses on power generation from gas and oil (cf. chart 2). The fact that about 70% of these emissions are air conditioning-related emphasises the urgency of considering more sustainable cooling alternatives.

As a reflection of this, the total CO2 emission has also increased. The annual power consumption in the region is around 398TWh/annum, which equals to CO2 emissions of approximately 295 million metric tonnes per annum.3 This high value stems from the region’s energy mix, which focuses on power generation from gas and oil (cf. chart 2). The fact that about 70% of these emissions are air conditioning-related emphasises the urgency of considering more sustainable cooling alternatives.

This article will briefly explain the absorption principle and absorption system characteristics, before discussing the applications of solar absorption cooling and its combination with compression chillers. The discussion will then turn to the analysis of the electricity and CO2 savings of a SAC system compared to a conventional compression system. Finally, the article will introduce a recent SAC reference at the European Football Association’s (UEFA) new headquarters.

COOLING BEYOND ELECTRICAL COMPRESSION: ABSORPTION COOLING AND SAC

In contrast to the electrical compression cycle, absorption is based on thermal-driven natural circulation of water (refrigerant) and lithium bromide (solution), both of which are environmentally benign substances.

This principle allows hot water-driven absorption chillers to generate chilled water temperatures as low as 6°C at hot water inlets of 70°C to 95°C from such diverse heat sources as, for example, co-generation, industrial waste heat or solar thermal.

This principle allows hot water-driven absorption chillers to generate chilled water temperatures as low as 6°C at hot water inlets of 70°C to 95°C from such diverse heat sources as, for example, co-generation, industrial waste heat or solar thermal.

In addition to its reduction of electricity consumption and its benign substances, the enduring non-mechanical and almost maintenance-free design is among the major benefits of absorption chillers. But in contrast to electrical chillers, absorption chiller systems require additional hydraulic pumps and a cooling tower. However, the average absorption system will require only 40% of an equivalent electrical cooling system’s power consumption.

Solar assisted cooling represents an integration of conventional cooling and solar absorption cooling technology. Solar cooling systems obviously rely on solar thermal collectors, which provide hot water to the buffer tank. The buffer tank allows optimising the inlet temperatures into the hot water-driven absorption chiller, which will reject the heat via a cooling tower.

Depending on the system’s operational requirements, an additional back-up system might also be required, as absorption chillers rely on a constant hot water supply, which cannot be provided by solar collectors, for example, at night. Solar cooling, therefore, works best for projects whose cooling demand is concentrated over daytime, for example, offices and schools.

The significant advantage of such a system is that it can operate with 40% of power consumption of an equivalent compression unit, while providing chilled water from solar radiation, and as such, from a free and CO2-neutral energy source. The general rule of thumb provided by academics4 and the industry5 is that 1kW of cooling requires 3m2 of solar collectors (1 TR cooling requiring 10m2).

The benefits of solar cooling are obvious. As the cooling demand rises during the day, so does the performance of the solar collectors. Also, hot water-driven absorption chillers can operate from hot water inlets of 70°C. This means that solar cooling does not require Concentrated Solar Collectors (CSCs), but instead, can operate from hot water provided by standard collectors. But given the high cooling loads in the GCC region, the solar surface required for an entirely solar thermal-driven absorption system (considering required installation space, buffer tank capacity, backup solution, etc.) would be likely to smash the scales of economic and technical feasibility.

SAC systems appear better suited for the requirements of the GCC as the function of the absorption chiller is not to replace, but supplement the compression system.

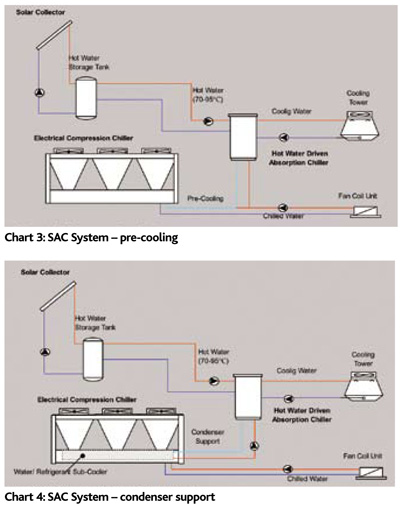

Absorption chillers in SAC designs provide “pre-cooling” for the compression chiller’s chilled water cycle, which reduces the Delta T of the electrical chiller, and thus, its electricity consumption (cf. charts 3). But absorption cooling in SAC can also be designed to reduce power usage by supporting the condensers of compression systems (cf. charts 4). Compared to an entire solar cooling plant, both designs allow for a significant reduction of the required solar square footage.

Absorption chillers in SAC designs provide “pre-cooling” for the compression chiller’s chilled water cycle, which reduces the Delta T of the electrical chiller, and thus, its electricity consumption (cf. charts 3). But absorption cooling in SAC can also be designed to reduce power usage by supporting the condensers of compression systems (cf. charts 4). Compared to an entire solar cooling plant, both designs allow for a significant reduction of the required solar square footage.

Imagine an office building with a cooling load of 100 TR. To cool the building entirely by solar thermal absorption, the required collector surface would be approximately 1,000m2. Due to solar installation requirements, it would be fair to assume a required solar installation space of 1,200m2.

While it might be hard to accommodate this surface, imagine the same building with a compression chiller of 100 TR, combined with a solar thermal-driven absorption chiller with a capacity of 30 TR. The solar collector surface would be around 300m2, with an installation space requirement of approximately 220m2.

Apart from the mere reduction of solar area (and related investments), SAC systems also better allow for the needs of retrofits into existing buildings, since absorption chillers can be combined with the existing chilled water distribution, or even share existing cooling tower capacities.

ENERGY SAVING AND CARBON REDUCTION – A CASE STUDY

In order to analyse the electricity and carbon savings of a SAC system in comparison to a compression cooling system, we have to first understand the electricity consumption of the latter.

For the purpose of illustration, let us consider once more, the above-mentioned example of an office building in the GCC region with a cooling demand of 100 TR. Let us assume that the compression chiller would operate at an average COP of 3.5. Let us further consider that the office would function 10 hours per day at 22 working days per month. Also, let us assume that the building’s cooling systems operate for nine months per annum at an average load of 60%.

The electricity consumption for the building can thus be calculated as follows:

Electricity consumption = 350kW/3.5 x 10h x 22 days/months x 9 months x 60% = 119MWh

The cooling-related annual power consumption for the building would thus be 119MWh.

If we want to determine the potential electricity saving of a SAC system for the same building, we would have to first consider the share of solar cooling in the total building’s cooling demand. It shall be assumed to cover 30% of the building’s demand by solar-driven absorption cooling.

As mentioned above, the electricity consumption of an absorption system is 40% of that of an equivalent compression system, which is why one can consider a 60% power saving for the absorption part of the SAC system. Given the GCC’s annual average of hours of sunshine/day it is fair to assume six hours of solar cooling hours/day. Furthermore, the absorption chiller shall cover the building’s base load, while the compression chiller would only switch on once the load exceeds the absorption chiller’s capacity. We can, therefore, determine an operational rate of 100%.

The annual power saving provided by a SAC system for the same building would then be calculated as follows:

Electricity saving/annum = 105kW/3.5 x (1 -0.4) x 6h x 22 days/mth x 9 mths x 100% = 21.4 MW

The annual electricity saving realised by the SAC system would thus correspond to 21.4MW or a respective annual power reduction of 18%.

Based on the GCC’s average energy mix, we can determine the annual CO2 emission saving. For this exercise, we presume a transmission end-loss of 10%, an average power plant efficiency of 38% and a CO2 emission factor of 0.24 of the average electricity generation:

CO2 Emissions Saving/Annum = {21.4 MWh x (1+0.1) / 0.38} x 0.24 metric t/MWh = 14.9 metric t

The change to a SAC system could thus reduce the cooling plant’s carbon footprint by 14.9 metric tonnes/annum or 18%.

A CASE STUDY: THE NEW UEFA HEADQUARTERS

The implementation of SAC systems is not limited to regions with high solar radiation and high cooling loads. When the Union of European Football Associations (UEFA) planned their new Swiss-based headquarters on the shores of Lake Geneva in Nyon, they had already decided that the building design should be based on the principles of sustainability and energy-efficiency. It was also determined that the remaining energy requirements should be covered by as much renewable energy as possible. Geneva-based architects Bassicarella developed the building’s circular design, which harmoniously integrated into the surrounding landscape while reducing the energy load. At the same time, the building’s renewable energy concept combined geothermal and solar thermal energy with photovoltaics.

The implementation of SAC systems is not limited to regions with high solar radiation and high cooling loads. When the Union of European Football Associations (UEFA) planned their new Swiss-based headquarters on the shores of Lake Geneva in Nyon, they had already decided that the building design should be based on the principles of sustainability and energy-efficiency. It was also determined that the remaining energy requirements should be covered by as much renewable energy as possible. Geneva-based architects Bassicarella developed the building’s circular design, which harmoniously integrated into the surrounding landscape while reducing the energy load. At the same time, the building’s renewable energy concept combined geothermal and solar thermal energy with photovoltaics.

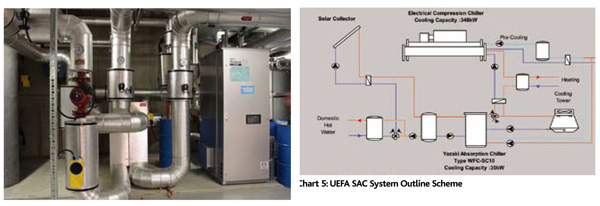

In addition to 90 vacuum tube collector, the building features additional 200m2 of photovoltaic, mounted on the building’s roof (see photo 1). The task was to align the cooling system with the high overall energy standards of UEFA’s new home.

The building’s collector array measures approximately 110m2 and generates a maximum thermal output of 55kW, used for heating and domestic hot water purposes.

However, during summer and transitional periods, when heating is not in operation, the building provides extra solar thermal energy, if not otherwise used.

This excess of solar thermal hot water was the initial point that led to considering the use of a hot water-driven absorption chiller. Given the limited solar collector array available, the solar cooling was designed to cover 10% of the building’s overall load. The selected absorption chiller generates 35kW of cooling at a hot water temperature of 88°C. One of the characteristics of the selected chiller is that it manages chilled water generation from hot water inlet temperatures as low as 70°C, which makes it ideally suited for solar applications. The chilled water is cooled at 7°C and stored in a chilled water tank with a capacity of 3,000 litres. If greater cooling capacities are required, the system is supported by a hydraulically reversible heat pump with a capacity of 348kW.

The refrigerating plant (cf. chart 5) is controlled in such a way that the use of cooling energy generated from solar energy is prioritised at all times. Heating and cooling are distributed around the building by means of a four-conductor system, which supplies hot and cold water to the fan convector heaters.

Starting operation in 2010, the UEFA’s SAC system is estimated to provide power saving of 2.1MWh, and based on the Swiss CO2-neutral energy mix, a related carbon emission saving of 0.4 metric tonnes per annum7.

The UEFA project shows that the feasibility of SAC systems does not rely on high solar radiation and demanding cooling loads. It also illustrates how SAC can effectively contribute to optimising a building’s overall energy efficiency, provided there is a careful integration into the overall energy concept.

SUMMARY

As the challenges posed by growing energy demand, increasing standards of building efficiency and reductions of CO2 emissions become an ever stronger aspect of new projects, alternative cooling technologies come to the fore. Solar-driven absorption chillers combined with compression systems are among the most feasible and affordable means to realise renewable cooling. Solar assisted cooling can accomplish high annual electricity savings and reduce CO2 emissions, especially in regions with strong solar radiation and high base loads. This is particularly true for the GCC countries, where base loads account for approximately 40% of the overall cooling loads.

SAC, thus, appears especially suited to contribute to improving energy efficiency and CO2 balance of cooling plants in the Gulf region. SAC can provide its benefits in two ways: as a renewable pre-cooling for (1) compression chillers’ chilled water cycles or (2) their condensers, which usually suffer from reduced COPs in high dry bulb temperatures.

Due to the manageable retrofit, SAC enables owners to complement existing conventional cooling plants with sustainable cooling technology, in order to achieve power savings as well as optimise carbon balances. Among them, the main advantage of SAC is, reduced investment as SAC neither requires hot water temperatures above 95°C, nor the extensive collector area required by a full-scale solar cooling design.

It is, of course, self-evident that SAC cannot present the all-in-one solution for the region’s energy and climatic challenges. The demanding wet bulb temperature in parts of the region remains an issue for the re-cooling of absorption chillers. But SAC does appear to have the potential for projects not merely confined to dry and arid climates. It is time to capitalise on solar energy – the region’s biggest energy asset, and turn it into cooling.

The authors are Head of Business Unit and Product Manager of Yazaki Europe Limited (Environment & Energy Equipment Operations), respectively. They can be contacted at arne.heuzeroth@yazaki-europe.com and kazuhide.ishida@yazaki-europe.com.

Footnotes and references

1 Cf. “Saudi Electricity Demand to Increase Dramatically by 2020, says Chief of Electricity Board”, Al Arabia News, May 26, 2011.

2 Cf. Miller, Keith: “The Prospects for Electricity Trade Between the GCC Countries”, Abu Dhabi Waste and Electricity Company (ADWEC), Abu Dhabi, 2005.

3 Cf. “International Energy Agency Electricity /Heat Data”, IEA, 2008.

4 Cf. Henning, Hans-Martin: “Solar Assisted Air Conditioning of Buildings. A Handbook for Planners”, Springer Verlag, Vienna, 2007

5 Cf. Aydemir, Murat: “Viessmann – Solar Assisted Cooling”, presented at the first GCC Solar Assisted Cooling Seminar, Dubai, May 24, 2011.

6 Base values refer to the respective default CO2 emission factors, cf. “Workbook of the Revised 1996 IPCC Guidelines for National Greenhouse Gas Inventories”, Intergovernmental Panel on Climate Change (IPCC), London,1997. Also cf. Graus, Wina: “International Comparisons of Fossil Power”, Ecofys, Utrecht, 2007.

7 Based on the predominantly carbon-neutral Swiss energy mix (55% Hydro, 40% Nuclear), the generated CO2 saving is relatively small cf. “International Energy Agency Electricity /Heat Data”, IEA, 2008. Assuming the GCC region’s energy mix, this value would correspond to a CO2 saving of 1.5 metric tonnes/annum.

Copyright © 2006-2025 - CPI Industry. All rights reserved.