Traditionally, air conditioning large spaces is an expensive and energy-consuming endeavour. However, High Volume Low Speed fan technology can yield energy and cost reduction by putting less pressure on air conditioners, says Dean Wood, and demonstrates how

Traditionally, air conditioning large spaces is an expensive and energy-consuming endeavour. However, High Volume Low Speed fan technology can yield energy and cost reduction by putting less pressure on air conditioners, says Dean Wood, and demonstrates how

Air conditioning is a necessity in the Middle East, given its geographical location, climatic conditions and the ever-evolving infrastructure. Product integrity, occupant productivity and humidity control are just a few reasons building owners and operators continually overspend to maintain interior area temperatures.

In recent years, improving the efficiency of air conditioning units has generated a modest amount of energy savings but lacks the major thrust needed to address the foremost concerns of sustainability and the long-term impact on climate change. Air conditioning remains an expensive and energy-consuming endeavour. This is especially true for large spaces, such as recreation facilities, distribution centres, atriums, shopping malls, aeroplane hangars and factories.

Large open spaces rely on numerous high tonnage units and extensive amounts of ductwork, booster fans, grilles and diffusers to generate and distribute conditioned air to all parts of the space. A constant temperature needs to be achieved for keeping these spaces comfortable, no matter what the outside temperature and no matter how high the cost. Although the goal of distributing conditioned air to large spaces has been achieved, air conditioning such areas has remained inefficient and continues to result in high capital and operating costs for building owners.

However, recent case studies have proved that High Volume Low Speed (HVLS) fans are capable of creating dramatic savings in energy consumption in large spaces where air conditioning is deployed. Energy savings is created through two main avenues – thermostat change and free cooling.

THERMOSTAT CHANGE

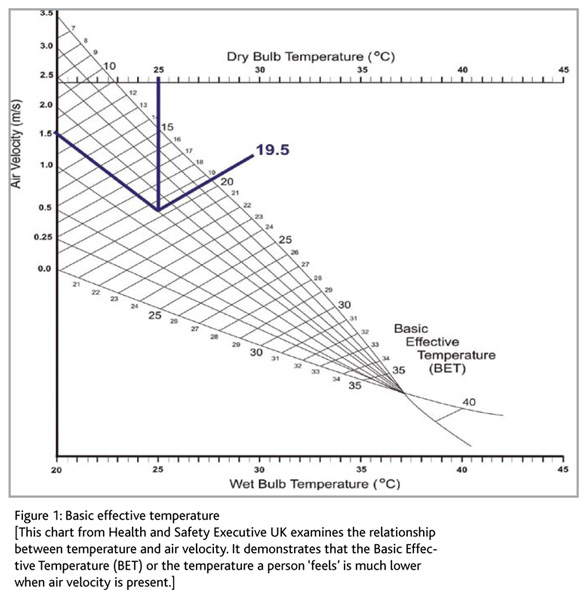

Let us first examine thermostat change. It is commonly accepted that wind chill factor lowers the apparent temperature, making the air feel cooler than it actually is. Thermostat change is achievable by better understanding the ‘wind-chill factor’ or Basic Effective Temperature (BET) created by HVLS fans.

Figure 1 examines the relationship between actual air temperature and the velocity at which it is moving. Armed with both these variables, we can successfully determine that at a temperature of 25⁰C with air moving at a speed of 1.5 metres per second, the BET is less than 20⁰C. This creates an environment which is too cold for occupants, encouraging the operator to increase the temperature set point and create continual savings. A savings of nearly 25% can be achieved by increasing the set point 3⁰C to 4⁰C.

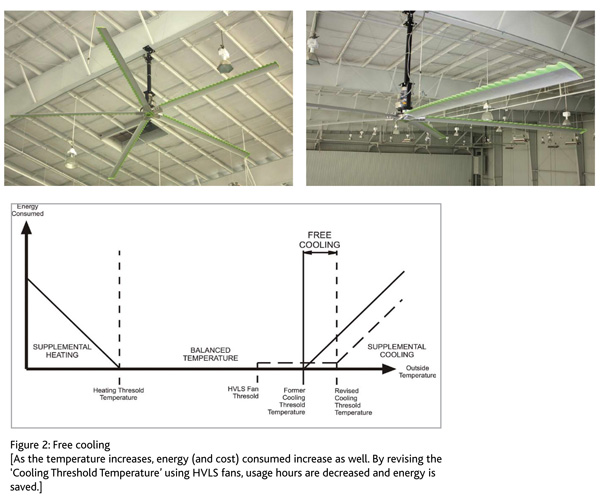

Further savings can be achieved by adjusting the ‘cooling threshold’ and attaining ‘Free Cooling’. Free Cooling is the period of time just before (and after) air conditioning is required. In terms of savings, free cooling is defined by a decrease in annual usage hours created by the capabilities of HVLS fan technology.

ENERGY AND COST SAVINGS

Figure 2 shows how energy consumed is directly affected by exterior temperatures. As the temperature increases, energy costs rise. By adjusting the thermostat set point, free cooling is automatically achieved, as the cooling threshold is now adjusted to a warmer temperature, decreasing usage hours and increasing savings. Free cooling creates even more savings, as the temperature decreases from peak summer temperatures. Operating air conditioning units is, therefore, now required for a shorter period of time.

New building construction projects at the design stage can account for even more savings. Knowing what HVLS fans can do in conjunction with air conditioning systems, consultants and engineers can now make adjustments to the cooling equipment required. It translates into nearly 85% less ductwork required, as the fans handle the distribution and circulation inside the space. Also, less tonnage is now required as the air conditioning units are working less and cooling to higher than traditional temperatures. These capital savings more than offset the investment in HVLS fan technology, saving capital now and continually generating savings over a period of time.

While it is true that HVLS fans consume additional power, this load is minimal. Most HVLS fans operate on 0.75 to 1.5kw motors with variable speed drives. This indicates that a single HVLS fan consumes less power than a typical hair dryer. Utilising multiple fans increases power consumed, but only marginally. The capital investment in the technology of HVLS fans is quickly returned with a payback period of less than two years. But it can be regarded as a perpetual source of saving.

The writer is International Sales Manager, Envira-North Systems, Canada. He can be contacted at: deanwood@enviranorth.com

Copyright © 2006-2025 - CPI Industry. All rights reserved.