Salah Nezar, a sustainability design specialist, is Sustainability Services Leader for Qatar Project Management (QPM)

Salah Nezar, a sustainability design specialist, is Sustainability Services Leader for Qatar Project Management (QPM). With a wide range of experience in designing and managing projects involving cutting-edge green technologies and forward looking design practices, he dreams of designing high performance buildings at the frontier of zero energy in the region, and finding solutions to solar cooling related challenges.

MY BACKGROUND

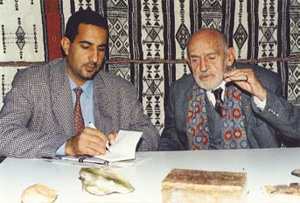

With Theodore Monod

I am almost 47. I was born in Batna, in Eastern Algeria. After obtaining my Baccalaureate degree, I learnt Italian and was about to join the Carlos Scarpa School in Italy and become an architect. It didn’t work, so I moved to building services, instead. I earned a degree in Genie Climatique from the University of Constantine, one of the few schools in the world of its kind, devoted to a five-year degree course on HVAC and refrigeration.

The course was, therefore, in a very narrow discipline, with a focus on air conditioning and building services. What I mean is, 90% of the people in the HVAC industry study the subject as part of their Mechanical Engineering degree, but we were capable of offering a wide array of choices in computing HVAC load calculations by the end of the third year of the curriculum.

I completed my degree in 1989 and went on to graduate school while working as an HVAC engineer for a local engineering office. I got a Master’s degree in Bioclimatique – a combination of passive design and intelligent active AC systems. It was specific for hot and arid areas. The research topic was sponsored by the Government of Algeria, in collaboration with the EU. I had to undergo a number of very specialised training programmes with ADEME (L’Agence de l’Environnement et de la Maîtrise de l’Energie) and l’Université Catholique de Louvain. They have one of the most advanced labs for Bioclimatique research.

During this phase, I had the chance to meet a number of top-notch sustainability specialists at the University of La Rochelle, and L’ecole des Mine de Paris. My discussions with the scholar, Theodore Monod are engraved in my memories on how to embrace sustainability as a mode of life and not as a buzzword.

At the end of the research work, I wrote a technical paper, which was selected by the World Energy Council in 1998 as the best of its kind, proving a rethinking approach in integrating passive and active energy conservation strategies in a single thermal model. I didn’t expect it to, but the paper changed my career and my life.

The year was 1998. I took the paper to the United States for a presentation in Texas. My plan was to be in the US for a few days, but I stayed on for years!

Subsequent to the presentation, in Texas, the University of New Orleans contacted me to join their energy conservation programme. I was in charge of the energy simulation lab and taught students numerical tools to conduct energy simulation and energy auditing, and discussed real case studies with them on intelligence buildings. It was a 4,000 level course.

FROM COLLEGE CAMPUS TO RETROFITTING

In 2001, I moved from the world of academics to the world of industry – to Dome Tech Engineering, in New Jersey. The firm specialised in commissioning and retrofitting, with a focus on pharmaceutical and medical facilities in hospitals. During my time there, I completed assignments for Pfizer, Johnson & Johnson, Merck, Baxter, in addition to a number of hospitals in the New York metro area, like NYU, Mount Sinai and Winthrop. It was an enriching experience, as the level of cleanliness involved was very high, and the designs had to be very stringent and specific. The assignment also involved trouble-shooting.

Speaking of trouble-shooting, let me cite an interesting anecdote from this period. In the pharmaceutical business, each product has a production line. One of these lines was serving a branded and well known medicine. From its starting day, generally, in summer, every year, the production line would go down, owing to humidity and high temperature.

The system, therefore, had to be shut down. This obviously had cost implications.

Speaking at a sustainability event in Dubai

Pfizer, in New York, called several companies to solve the problem. They all thought it had to do with air-balancing. But it was fortuitous that I looked at the data and decided to do water and air tests. When I looked at the test results, I noticed a shortage of chilled water. But that was not the crux of the matter. I asked for as-built drawings, and after doing some mathematical calculations, I concluded that the problem could be in the cooling coil. When we opened the AHU, we found that the coil was facing the reverse direction. Once it was flipped to the right direction, the system was able to achieve the design conditions despite a slight shortage in chilled water flow.

After Dome Tech, I moved to Kallen & Lemelson, in New York City. During this period, the firm bagged a contract from New York State Energy Research Development Authority (NYSERDA). I was fortunate enough to be in charge of managing the energy and sustainability segment of iconic projects in New York State. In all, I was in charge of 20 projects to recommend energy conservation measures and ensure their implementation in the design document in order to be eligible for the state incentives. The amount of incentives depends on the level of energy saved, generally quantified through a full year energy model.

My job was to run the energy conservation side of the projects, from the kick-off meeting to the completion of the design document.

I had to come up with forward looking ideas for energy conservation and generation. The measures concerned finding ways of using smart integrated systems for high performance buildings, using VAV instead of constant volume, use of advance controls in optimising the efficiency of the air delivery system such as demand ventilation control and static pressure reset, and finding ways to have smart chilled water delivery system, including the cooling plant sequencing optimisation. This gave me a lot of experience, because I was dealing with top engineering firms not only in New York but also worldwide, such as, JB&B, Cosentini, and Flack & Kurtz We worked on iconic hospitals, schools and green residential towers.

Besides the NYSERDA contract, I was heavily involved in the project of renovating the 100 year old lion shouse for the Bronx Zoo. It was the first landmark building in New York City to obtain the LEED Gold rating from the USGBC.

You see, the challenge in a landmark building project is that you can’t change the outside and you have to work around it. The zoo project was complex, because it posed other unique challenges. For example, in the exhibition area housing the Nile Crocodiles, Lemurs and other animals from Madagascar, we had to create a specific environment for the animals and plants. We used advanced techniques in providing optimal indoor environment, like dynamic skylight composed of three layers to optimise daylight harvesting and minimise sun load in summer. It was the first time in the US that dynamic skylights were deployed.

At the plant level, we succeeded in integrating the existing zoo cogeneration system and absorption chiller with a new 200 KW fuel cell unit, and a skid of ground source heat pumps. The amount of energy saved was just outstanding for a historical building.

It was soon time to move again, as I got an offer from Syska Hennessey in New York, for the post of Supervisor Engineer. It was a whirlwind time.

While there, one of the first projects was designing the cooling system for a data centre in downtown New York. It was a challenge, because in New York City, space is at a premium, and there was no space to add new cooling towers. To overcome the problem, we took part of a floor and removed the window frames. This allowed for the air recirculation for the purpose of heat rejection. All the units had to be custom made.

During my tenure with Syska, I worked on retrofit projects and many LEED buildings. I was also involved in the commissioning of 1, Bryant Park, which is the Bank of America building. It was the first LEED Platinum high-rise building in the United States. So, straddling between a zoo and a high-rise building was quite an experience.

I was also involved in the retrofitting of the headquarters of the Bank of America building in Charlotte, North Carolina. The proposed design, to achieve a LEED Gold rating, needed a smart air delivery system using passive chilled beams, combined with an underfloor air distribution (UFAD) system. But we ended up with smart VAV systems! The construction cost of the smart system of the first system was $42/square feet, while the classic VAV system was $17/square feet. The difference was quite large, and the bank decided to go for the second solution.

For Vachovia, again in North Carolina, I worked on all the preliminary LEED scoring sheets and recommended a strategy based on a variety of solutions to get LEED Gold for the entire complex. We worked with an engineering firm in Georgia and helped them develop an execution plan for the sustainability strategy.

FROM THE BIG APPLE TO GUANGZHOU

John & me, Bryant Park, NYC

After the Vachovia project, SOM in Chicago contacted me. They had just got a project to design the first zero energy, high rise building in the world – the Pearl River Tower, in Guangzhou. It was designated to be the most energy efficient, super tall structure in the world. I accepted the challenge, because it was one of the most complex projects I have undertaken in my life. It had all the advanced technology and design practices for high- performance buildings (HPBs). There were four cavities in the building structure to house vertical wind turbines. This integration allows the turbine to generate electricity 18 times higher than if they were installed at the ground level. The top of the building was covered with PV cells to generate electricity and reduce the cooling loads. A double-skin (ventilated façade) was used to minimise the space-cooling loads. Blinds within the cavity were covered with PV cells to energise the shading control system. Daylighting harvesting was optimised with the use of efficient lighting to reduce electrical consumption.

Understanding the building loads and using psychometrics encouraged us to opt for a separation between sensible and latent loads. We used chilled ceiling with an underfloor air system for the interior spaces. The load with the perimeter zones was high to a point we had to use passive chilled beams instead of chilled ceiling.

The main challenge was defining a common understanding about the design intent within the design team and lay down a platform able to integrate successfully a set of energy conservation measures, acting at different systems level, and energy generation opportunities from sun and wind. There were moments where we felt lost between divergent inputs from the parties involved in the project. During the closing phase, the stress was at the apogee for the entire team, particularly for me as the lead HVAC engineer.

The project was a huge success. More important, it succeeded in convincing the international panel, which was doing the design review.

Another prestigious project was the assignment involving the new international terminal at Mumbai’s Chhatrapati Shivaji International Airport – a 2.5-million square foot project. It was 12 times the size of a football field. The challenge was to design the new one in phases and integrate it with the existing one. All this had to be done in 20 weeks. We updated cooling load calculation 15 times during those 20 weeks. We had to take into account constant architectural modification, interior design adaptations, life safety, IT and security concerns. We aimed for a high-efficiency building. The clients were pushing for reliable and efficient systems that could also achieve LEED rating.

To suit the air delivery path, as imposed by the architectural team, we had to provide design a special air column. We designed it in-house and sent it to the manufacturer to make it to suit the load requirements of the airport. The project gave me a great sense of satisfaction, as the architectural team (based in New York) and the client were very happy with our work.

UAE-BOUND

After the airport project was completed, I joined KEO International Consultants, Abu Dhabi, as Head of the Mechanical Department. I had to start the department from scratch. I worked on numerous project, like the design of the Dar Al Dhabi in Abu Dhabi.

As a team leader and manager, the big challenge was in understating the energy flow of a team and act as a regulating point to keep the flow going, regardless of the situation. In the beginning, the mechanical team had a heterogeneous pattern in providing engineering solutions. Our design document did clearly reflect this issue, and we worked extremely hard to make our deliverables consistent, useful and in-line with the international norms. I was successful in involving every member of the team in the process of updating CAD standards, several standards and specification without disturbing the production or missing any deadlines.

During my stint in the UAE, I also became the Vice President of ASHRAE’s Falcon Chapter, and the Chair of its Sustainability Committee, where we were involved in a number of activities with Masdar and Estidama. I made some contributions to the work involving the Pearl rating system with the pioneering team, right from the initial stages.

QATAR BECKONS …

From Abu Dhabi, I moved to Qatar. The peninsula needed experts in elevating the level of design and management to help in design reviews and value engineering. Today, my assignment involves activities similar to the ones I was involved in while in New York.

In my opinion, the leadership in QPM has the vision to create a worldwide leading project management firm. The strategic business models are under continuous change to meet the market transformation. Helping host the 2022 games is one of the challenges we are taking very seriously, indeed, at QPM. I’m happy that I’m providing the leadership needed to actualise the company goals. I believe I’m bringing something unique to the initiative. Here, I’m not talking about sustainability in marketing terms but about specific, defined, measurable goals in sustainability.

THE HUMAN ELEMENT

Pearl River Tower under construction

The question often asked is, why should we focus on IEQ and human productivity? The answer is, because it brings thermal comfort, acoustic comfort, visual comfort, olfactory comfort and, not to forget, the ergonomic aspect. If, by putting these together, you get optimal IEQ, you will enhance productivity by five per cent. Do consider $2 per square feet on energy, $3 per square feet on rent, $500/year per square feet on wages, $2/square feet in taxes in midtown New York. So, if you can save just five per cent of that, imagine how much you are saving! This will automatically change the owner/tenant equation. Instead of high rent, the tenant will pay a lower rent. But the owner will get 35% of benefits from the tenant – base rent plus incremental rent.

A case in point is 1, Bryant Park. The Durst Organisation gave it at $120/square feet rental. But at the end of the day, they got $150, because people now want to move away from sick building syndrome and dark spaces. They are looking for connectivity with Nature and green.

I BELIEVE …

I believe that we should focus on energy efficiency and energy generation. It starts with cooling load optimisation. And in this region, 65% is earmarked for HVAC. Therefore, the best way to have sustainable design is to figure out how to reduce cooling load. My experience is that there are different tiers in energy conservation. Let me explain:

Tier 1: Optimisation of building envelope – reduce glazing, shading, orientation and ventilated façade.

Tier 2: Reduce the internal load – lighting load and plug loads–

Tier 3: Smart buildings or advanced control systems

Tier 4: Efficient or enhanced commissioning to match the intent of design with construction practices – you can design the best system but end up having a bad system, depending on the quality of construction. Avoid “You get what we give you” from the project vocabulary.

Tiers 5: Solar cooling to shade half of the electrical load.

Tier 6: Ensure enhanced IEQ – human beings should feel this is the right place to be in. Being comfortable doesn’t mean depleting extra natural resources that we should be saving for future generation

HOW I WANT TO CONTRIBUTE TO THE REGION

I would like to contribute to the growth and development of the region by offering my experience to the service of management firms and helping them in achieving high-performance buildings (HPBs) in various ways, be it by way of optimising energy and water consumption or by reducing carbon emissions. I think I can do this by suggesting the best different approaches.

One of my key aims is to contribute to finding solutions for solar-cooling challenges. If we can hit upon a viable solution, we can really reduce specific load by 40%, at least, at the plant level. The focus is on how to find smart alternatives to produce chilled water. We have the highest solar density in the world, and we need to benefit from it. Paradoxically, we also need a lot of water (for the absorption chillers), and we need to find a way to cool the condensing water going to the chiller. I am working on this. Maybe we will find a way to create a prototype in producing the system.

I think I can also help in putting a high efficiency approach in place in building services – some people deploy VFD, but it does not work efficiently, either because the sensors are put in the wrong place or the wrong valves are selected. So, valve authority calculation is important. I think that’s the only way we can know that the system is working in part load. If a building has 40% load, the plant should mimic and have 40% operation. Realistically speaking, if you pay for a system with part load control capability, but your chiller does not see it, what is the use?

MY MENTORS IN LIFE

My mom was my first mentor. She never went to big school, but she had a strong personality and sense for a sustainable way of living. My father encouraged me to have a good education and a passion for work. His words did light my path during critical moments in my life.

Apart from my parents, I had a number of other mentors in Algeria. Every one of them nurtured my talents. In New York, Al Dechiara was my mentor. He had spent 52 years with Syska Hennessy, and was still working at 75. He was a walking reference book. John Maglaiano, the then CEO of Syska, was another mentor. He gave me access to opportunities.

In a way, I consider even the young guys who work with me as my mentors, because I learn something from them when they come asking, “Why do this?”

Theodore Monod, the French environmentalist and scholar and Rafat Girgis, are people I have learnt from. I remember Prof Boudemine Belkhouche of the Tulane University, New Orleans, Michael Thoresen, Rob Bolin and James Regan at Syska Hennessy, as people who have helped me.

I’m particularly grateful to Dr Edwin Russu, Dr Carsie Hall and Belgacem Hizoum at the University of New Orleans, for taking me under their wings. I couldn’t speak English when I went to the United States. I was in Downtown New Orleans with $20 in my pocket and no home or friends. It was a turning point in my life. The question in my mind at the time was, should I go back or stay? I stayed back, because I found friends and the strength to continue. Russo, Hall and Belgacem were there to help and will remain as friends for ever.

Though I had a brief stint at SOM, I consider my experience with them as a very enriching one. People there respected you and your experience. The support provided by Roger Frechette, Russell Gilchrist, Phil Enquist and William Baker have had a considerable impact on my productivity. Unfortunately, I had to move from there, owing to family reasons.

MY FAMILY

My wife’s name is Nadia. She loves trees and green spaces. I have a three-year-old son. His name is Abdel Aziz Sultan.

For us, it’s not about talking sustainability and driving an SUV. We have a social responsibility in our personal life.

MY INTERESTS

I was a university-level soccer player in Algeria. We won the Algerian cup in 1986. I was goalie. My father was a part-time soccer coach in Batna. So I grew up on the soccer field.

I play the game sometimes now. For regular exercise, I go on long walks. For me, walking is a hobby. I think when I walk.

I like reading. Alchemist by Paolo Coelho has had a profound influence on my life.

I also like writing. In fact, I was a part-time journalist and wrote for newspapers like El Massa, Al Atlas and Al Mountakheb in Algeria. I used to write on sports and on environment, since I liked these subjects. I can write in English, French and Arabic. I also participated in a couple of television shows in the early 1990s. I took classes in technical writing. I attended Université de Paris-8 for technical expression.

I also like films and was lucky to be involved in them from the point of view of my profession. I was among the few engineers who previewed the movie, An Inconvenient Truth and met Al Gore personally. I was called in as a preview expert for Chris Paine’s ’s film, Who Killed the Electrical Car? Michael Moore led the Q&A panel, and we had a very long debate that night on real sustainability issue involving a number of celebrities and journalist living in New York Media. I count these among important experiences of my life.

MY PHILOSOPHY

I think we have to give. Life is about giving without expecting. “Don’t create boundaries” is my guiding principle. Every person has a positive side, regardless of roots or religion. I have nurtured my philosophy from those who have been kind to me.

I believe that there should be a spiritual aspect to our life. We need it to balance stress.

Copyright © 2006-2025 - CPI Industry. All rights reserved.