Though there are a couple of caveats to be considered, HFC blends are emerging as potential alternatives to HCFC22 for air conditioning systems, says Dr M Ramaswamy

Though there are a couple of caveats to be considered, HFC blends are emerging as potential alternatives to HCFC22 for air conditioning systems, says Dr M Ramaswamy

Hydrochlorofluorocarbon-22(HCFC 22) known as R22 is a refrigerant commonly used in commercial, industrial and air conditioning systems. With effect from this year, manufacturers will not be allowed to use R22 as a refrigerant in refrigeration and air conditioning equipment as per the international protocol. This is an important milestone in the phase-out of R22. The air conditioning system manufacturers will only be able to use pre-existing supplies of R22 to produce new air conditioners and heat pumps. These would include R22 recovered from existing and recycled equipment.

The US Environmental Protection Agency (EPA) recently announced the final rules regarding R22 equipment installation and servicing, as well as production allowances of HCFC refrigerants. The EPA has reviewed several alternatives to R22. But there is no exact replacement to it, though researchers throughout the world are working to find suitable alternatives. One impediment is that every substitute refrigerant requires some change in the system design.

As far as the earlier CFC phase-out was concerned (mainly R12, used in refrigerators, automobile air conditioners, centrifugal chillers etc) and R502, substitute refrigerants with thermo-physical properties very similar to those of the original working media, were available. One could, therefore, replace the existing working media with something else, without significantly losing capacity or efficiency. However, phasing out refrigerant R22 in the existing machinery, has proven to be more complicated than phasing out CFCs like R12.

Usually, Ozone Depletion Potential (ODP) and Global Warming Potential (GWP) are the two issues to be considered while selecting a suitable alternative refrigerant, in addition to other thermo-dynamic and thermo-physical properties. The former is as per the Montreal Protocol and the latter is as per the Kyoto Protocol.

The ideal substitute for the original refrigerant should be non-toxic, non-flammable, chemically stable, compatible with the refrigeration system materials and lubricants and have transport and thermodynamic properties similar to or better than the original refrigerant. In addition, the ideal substitute should have zero Ozone Depleting Potential (ODP) and low Global Warming Potential (GWP). But unfortunately, so far, there is no such single substance, which possesses all these properties.

At present, the alternative refrigerants generally fall into three broad groups. They are: HCFC and HCFC blends; HFC and HFC blends and Natural refrigerants. Most of the HCFC blends have been developed to provide a low-cost retro-fill and are particularly useful in DX CFC systems. Besides, in any case, HCFCs are to be phased out, and hence, this group does not merit much attention.

Natural refrigerants like ammonia and hydrocarbons have excellent thermodynamic properties, but flammability and compatibility with materials used for refrigeration system design limit their applications to only certain types of systems. However, this group is being supported by researchers, especially from the European Union due to its low GWP effect.

The European Union’s F-Gas Regulation No 842/2006 became law on July 4, 2006. F-gases include all HFC refrigerants, such as, R134a, and blends containing FGases such as R407C, R410A and R404A.

Handling, recovering, supplying, installing, manufacturing or owning equipment containing HFC refrigerants in stationary equipment in any country in Europe have legal obligations under the F-Gas Regulations. Recently, an environmental pressure group has attacked British supermarkets for failing to phase out the use of hydro fluorocarbon (HFC) gases in refrigeration systems. Supermarkets in the UK are seriously planning to make their stores HFC-free in the coming years.

It is apparent that there are a limited number of pure fluids that can function as substitutes for CFCs and HCFCs. Mixing of refrigerants allow adjustments or tuning of the most desirable properties to provide suitable alternatives. In the process, however, the other properties are also altered. The ultimate objective is, of course, to develop a mixture and obtain the perfect fluid with all the desirable properties within the operating range.

Mixtures provide a flexibility of modulating the capacity by varying the composition of the constituents. Refrigerant mixtures are solutions, that is, they have constituents which are equally dispersed and cannot be mechanically separated. There are three categories of mixtures.

Azeotropes

This class of refrigerant mixture behaves as if it were a single component during its phase change. It needs to be borne in mind that in the phase change, the proportion of each constituent in the new phase is the same as in the original phase. This property is of great use when the refrigerant mixture leaks and it has to be recharged.

Near-azeotropes

Azeotropes rigorously exist at only one composition for a given temperature and pressure. However, for all practical purposes, minor deviations are acceptable for many refrigerant systems. The term, “Nearazeotropic Mixture” (NEARM) is used for this broader range. The advantage of utilising this category is that many more possible alternatives become available.

Non-azeotropes

Non-azeotropes change their composition continuously during phase change. These mixtures do not possess a sharp boiling point, but boil over a range of temperatures. This feature is intimately tied to the improvement of a system’s efficiency, if appropriate hardware changes are made to the system heat exchangers.

The change of temperature with phase change is called Temperature Glide. When heat transfer fluids exchange heat with Non-azeotropic Refrigerant Mixtures (NARMs) in a constant current flow mode, the thermodynamic irreversibility can be reduced by matching the temperature glide (NARM side) against the temperature drop (Heat Transfer Fluid side), resulting in an increase in the coefficient of performance.

Non-azeotropic blends of refrigerants are seriously being considered as replacements for environmentally damaging pure refrigerants. Generally, the following criteria are used to select a mixture as refrigerant:

(i) Volumetric capacity

Unless major changes in the compressor are made, the volumetric capacity of the mixture should be close to that of R22 in a single evaporator system, especially for the drop-in tests. For a given mixture, this requirement suggests that at least one of the components of the mixture should be more volatile than R22. This means that the normal boiling point of the component should be less volatile.

(ii) Gliding temperature difference.

Theoretical and experimental research has shown that the increase in the COP with non-azeotropic mixtures largely comes from correctly matching the temperature glides of the refrigerant and heat exchanging fluid stream.

We will now analyse the HFC blends group, as a majority of air conditioning manufactures in the United States prefer these refrigerants. HFC blends have zero OD, but still have noticeable GWP.

Around 1990, global warming resulting from the release of man-made gases became a major environmental issue. The largest contributor to this is carbon dioxide from burning of fossil fuels. Although the GWP ratings are slightly higher for HFC-based refrigerants, compared to R22, they do not provide an accurate representation for air conditioning systems that have both direct and indirect effects on global warming.

The direct effect, which GWP measures, comes from refrigerant release into the atmosphere through leaks. The indirect effect is a function of energy consumption necessary to produce cooling.

Air conditioning systems using electricity indirectly influence global warming through the release of carbon dioxide and other greenhouse gases from combustion of fossil fuels at the electric generating station. Researchers, therefore, have developed an index called the Total Equivalent Warming Impact (TEWI) that considers both the direct and indirect global warming effects of a refrigerant. However, since HFCs have high GWP (although lower than those of CFCs), every effort must be made to prevent the leakage of these refrigerants while considering them as alternative refrigerants. Zero flammability and zero toxicity are the two favourable properties which make HFC-based refrigerants a popular alternative in both existing and new systems.

There are many HFC blends available in the market. However, we will restrict our discussion with R410A in detail and R 407C in brief because, these two HFC blends are emerging as potential alternatives to R22.

R410A is emerging as a substitute for new systems while R407C is emerging as a potential retrofitting refrigerant. From the thermodynamic analysis of the properties of these refrigerants, it is observed that the volumetric cooling capacity and a vapour pressure curves are close to that of R22. In theory, while reviewing various literatures, many have argued that these refrigerants would be a suitable substitute for R22.

R410A:

R410A is a blend of HFC-32 and HFC-125 (50/50 wt %). It is an azeotropic refrigerant. It performs very much like a single component refrigerant. The physical and chemical properties of R410A are very similar to those for R22, as well as most of today’s HFC refrigerants.

In 1996, the EPA formally recognised R410A as a substitute for R22. Leading chemical companies have made a strong effort to sell R410A to air conditioning manufacturers as a longterm replacement for R22. Following are some of the positive points for considering R410A as an alternative to R22, especially for new air conditioning systems.

Higher capacity equipment

Equipment designed for R410A has demonstrated up to 40% greater capacity when compared to current HCFC-22 equipment. It allows for smaller equipment sizes. Majority of the customers prefer smaller size equipment.

Easy servicing

As it is an azeotropic mixture, it behaves almost like a pure refrigerant, and therefore, it can be repeatedly topped off.

Safe and easy to use

R410A has an A1 ASHRAE safety classification, which means, it has lower toxicity and no flame propagation.

Higher efficiency

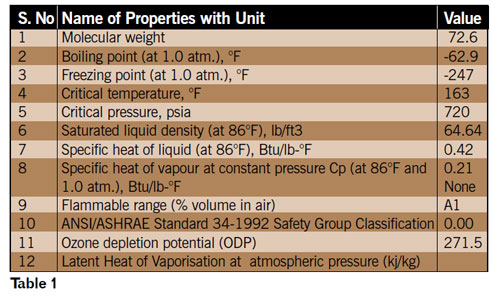

R410A systems exhibit about 10% increase in the Coefficient of Performance. Some of the R410 properties are given in Table 1:

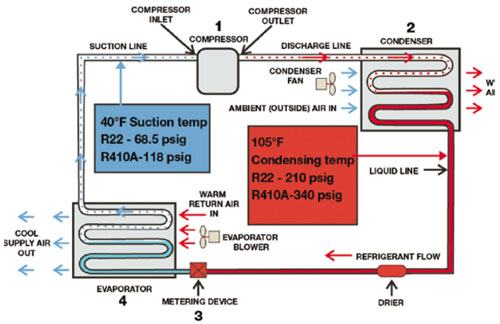

Figure 1 above shows the comparison of pressures of R22 and R410A in a simple refrigeration system.

R410A operates at a significantly higher pressure than R22. This may seem to be a negative characteristic of this refrigerant. But this negative point has forced designers to come up with more robust designs and superior control and protection techniques. Because of the higher pressure for R410A, most system components have been designed with increased wall thickness. Thanks, therefore, to the robust design, the system reliability has improved. R410A pressure drop is also less than R22.

A LEED pre-requisite is that HVAC equipment must not use a CFC refrigerant. R410A is one of the green refrigerants and can earn extra LEED point. But it has to be borne in mind that R410A cannot be used as retrofitting refrigerant applications because of the higher pressures associated with it.

Most R410A systems use a Polyolester lubricant (POE). It is to be noted that POE lubricants readily absorb moisture, and therefore, minimise exposure of lubricant or internal parts of the system to the atmosphere. Proper care should be taken while handling lubricants of this refrigerant. Following are a few tips to handle the POE lubricant:

Electronic leak detectors can be used for detecting any leak. But the detector must be capable of detecting a HFC refrigerant. It is to be noted that older leak detectors designed for R22 may not be sensitive enough to detect R410A. Use of halide torches should be avoided as they cannot effectively detect R410A refrigerant leak from the system. Also, using soap solution is not advisable as small leaks may not be detected with it. But UV-sensitive dyes can be used effectively.

Service technicians who work on R410A systems should use approved service tools to handle the high pressures of the system. These include gauges. Manifold gauge sets require an 800 psig high-side with a 250 psig lowside and all hoses should be rated for 800 psig. Recovery cylinders require a 400 psig service pressure rating and use cylinders approved for R410A.

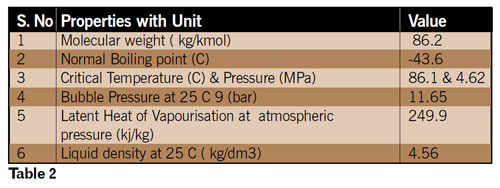

R407C has a potential use in retrofit applications, after the necessary system changes have been made. It is a blend of R32, R125 and R134a (23%/25%/52%). It is a zeotropic compound. It has been formulated to closely match the properties of R22. Table 2 shows a few of the essential properties of R407C. It is one of the green refrigerants and can earn extra LEED point. (See Table 2)

R407C has a large temperature glide, which makes it incompatible with some heat exchangers, especially with flooded heat exchangers. Therefore, this refrigerant should not be used in centrifugal chillers. This should be used in plant with counter-flow plate heat exchangers.

R407C’s ODP is zero and GWP is 1526. It has A1 safety classification. Its thermodynamic properties make it suitable as a refrigerant for medium and high temperature applications in residential and commercial air conditioning. We can use R407C in R22- equipment without losing either capacity or efficiency significantly.

As R407C has similar properties to R22, it will be possible – with few modifications – to use it in the same equipment designed for use with R22

While retrofitting the R22 system with R407C, one can observe the following:

Following points are to be considered while dealing with R407C, especially during serving air conditioning equipment:

When the Montreal Protocol has phased out CFCs in the developed countries and has a regulatory regime for the phase-out of HCFCs, it is still is a major problem in developed and developing countries. The global market will continue to develop and introduce new refrigerant chemicals. When replacing CFCs like R12 in existing machines was an issue, a substitute was found (R134a) with thermophysical properties so close to R12s that a unit subject to a refrigerant retrofit to it presented essentially the same performance and behaviour as before the retrofit. But when it comes to replacing R22 in the existing machinery, things become complicated due to the fact that none of the commercially available substitutes have thermo-physical properties very similar to that of R22.

Thus, using any of them in existing facilities will, in many cases, imply not only changes in capacity and efficiency, but also new types of behaviour, either not experienced with R22 or previously not considered significant. Therefore, proper care and professional approach should be adopted while selecting alternative refrigerants to R22, both in new systems as well as in the existing systems.

The writer is Technical Expert, Royal Estates Office of His Excellency, Head Of Royal Estates Affairs, Muscat, Sultanate of Oman.

Copyright © 2006-2025 - CPI Industry. All rights reserved.